Hydraulic design method for asymmetric solid-liquid two-phase flow centrifugal impeller

A centrifugal impeller, hydraulic design technology, applied in mechanical equipment, non-variable-capacity pumps, liquid fuel engines, etc., can solve the problems of poor non-destructiveness, reduced production efficiency, changes in slurry performance, etc., and achieves improved streamline distribution. The effect of improving clogging and entanglement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] Design requirements: the flow rate under design conditions is 0.096764 cubic meters per second, the head under design conditions is 60 meters, the speed is 2950 revolutions per second, and g is 10 meters per square meter.

[0088] (1)

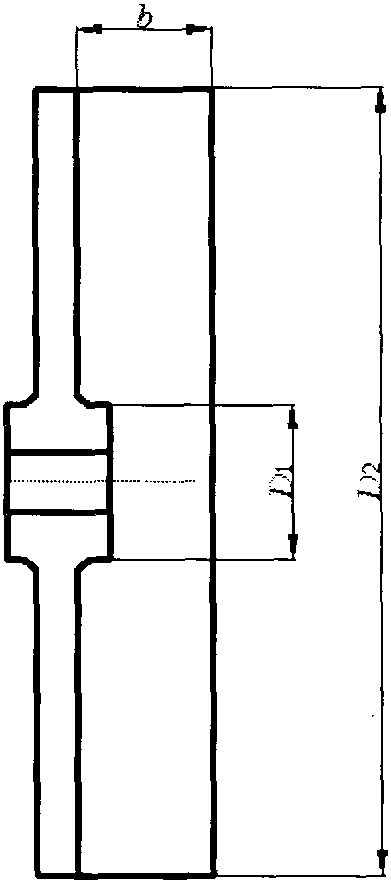

[0089] (2) Impeller inlet diameter:

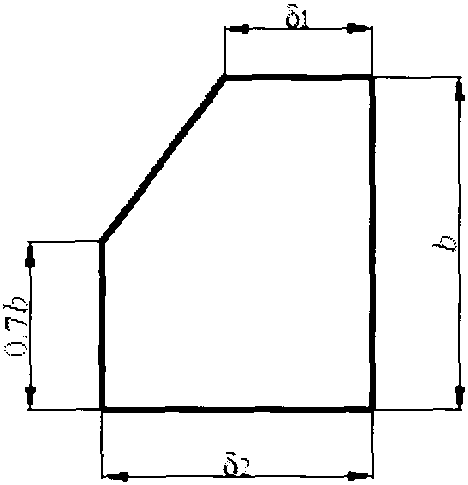

[0090] (3) Blade inlet installation angle:

[0091] (4) Blade outlet installation angle:

[0092] (5) Impeller outlet diameter

[0093] (6) Blade width:

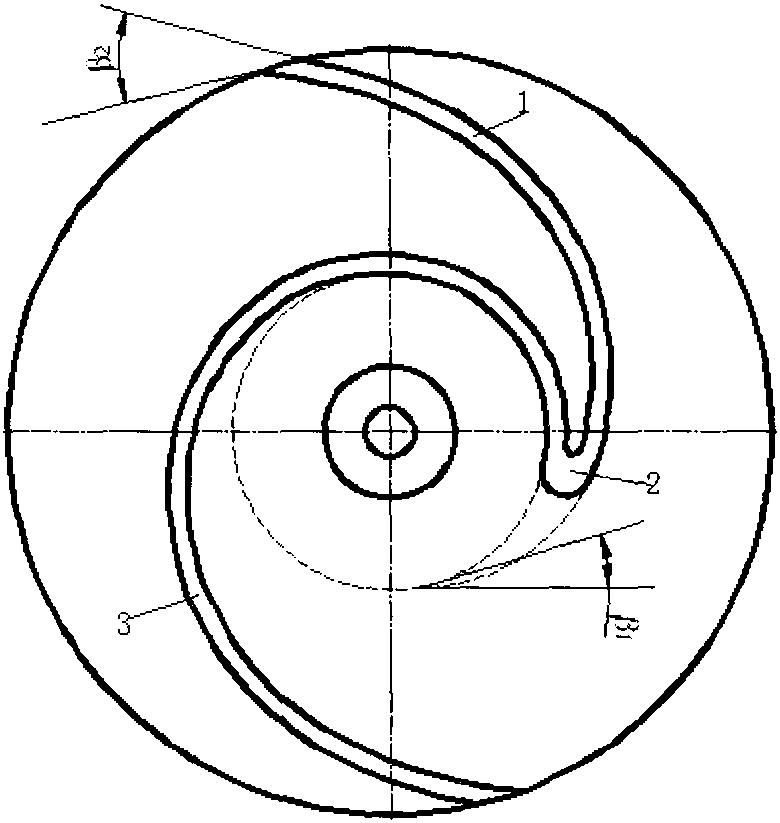

[0094] (7) Streamline equation of working face with long blades:

[0095] (8) The streamline equation of the short blade face:

[0096] (9) The polar equation of the size and fillet of the impeller:

[0097] (10) Blade bottom thickness: δ 2 =0.00012n s +0.003955=0.00012×100+0.0039≈0.016

[0098] In the design process, the selection of other coefficients needs to be selected according to the actual situation. For example, the shape of the blade inlet needs to be selected according to the shape of the inlet suction chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com