A kind of anti-corrosion steel rib reinforced spiral steel pipe and its manufacturing method

A technology of spiral steel pipe and manufacturing method, which is applied in the direction of pipe, rigid pipe, pipe/pipe joint/pipe fitting, etc., can solve the problems of large pipe wall thickness, high maintenance cost, difficult control, etc., and achieves high production efficiency, reliable quality, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

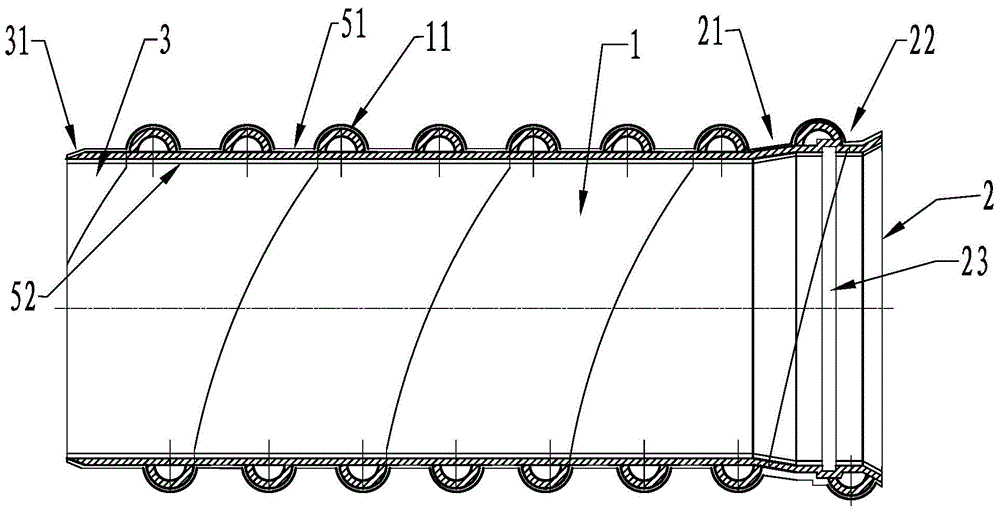

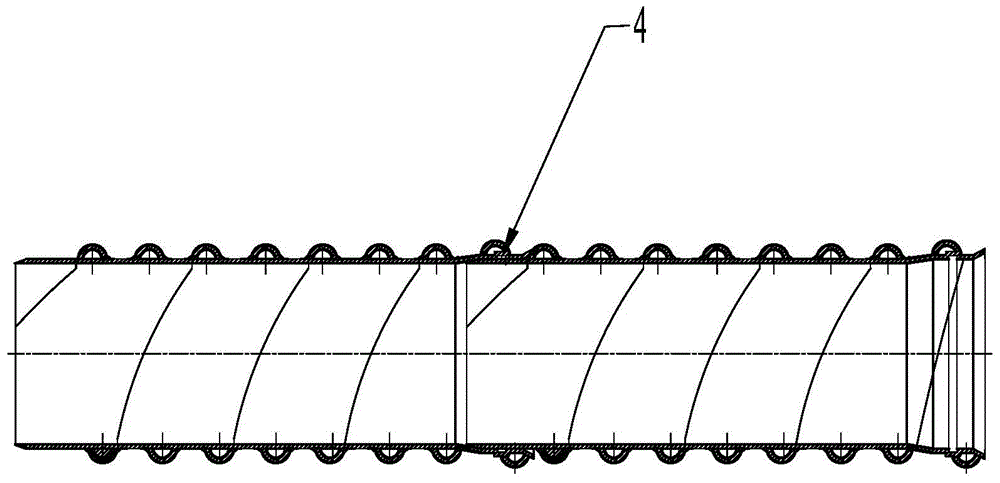

[0078] Embodiment two, combined with Figure 8 ,

[0079] The difference from the first embodiment is that the spiral steel rib is not welded on the pipe body, but integrally formed with it. Use the steel rolling system to directly roll the thick steel strip with steel ribs, and then weld it to form a spiral steel pipe, then make the socket, and finally carry out protective treatment and inspection. Forms an all-steel pipe with helical ribs. The specific process is as follows:

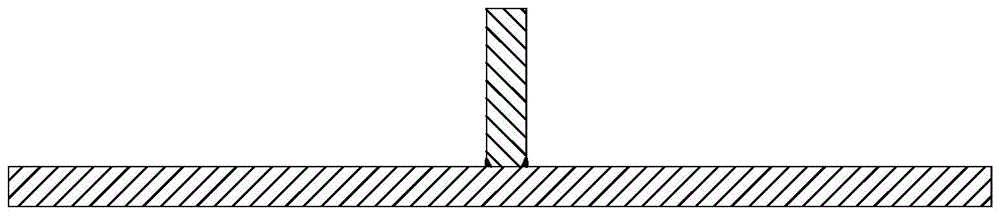

[0080] In the first step, rolling a continuous steel plate with steel ribs;

[0081] The second step is to use a spiral winding machine to wind and weld to form a steel pipe with spiral steel ribs;

[0082] The third step is to cut to length, remove the steel rib at the socket, and seal and repair the open end of the steel rib.

[0083] The fourth step is to preheat the two ends of the steel pipe, and carry out the shaping of the socket and the socket. Specifically, make the socket (2) and the soc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com