Extrusion type vertical air conditioner

A vertical air conditioner, extrusion technology, applied in heating and ventilation hoods/covers, etc., can solve the problems of increasing R&D, production, material and transportation costs, increasing the number of assembly parts of vertical air conditioners, and increasing the complexity of assembly parts. , to achieve the effect of increasing material and transportation costs, increasing the number of assembly parts, and reducing research and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

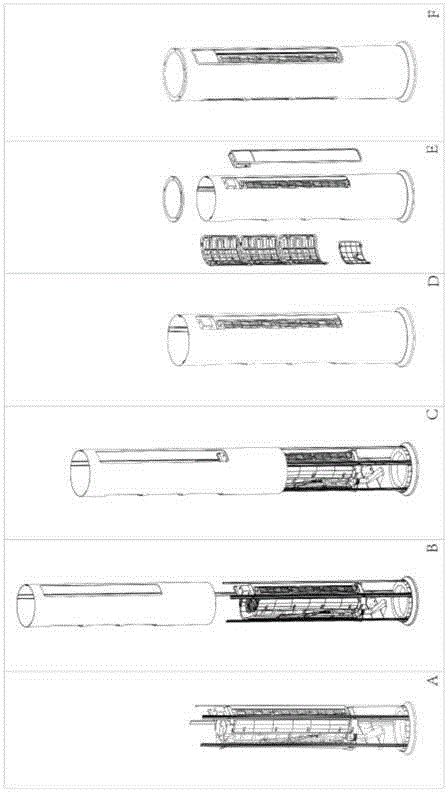

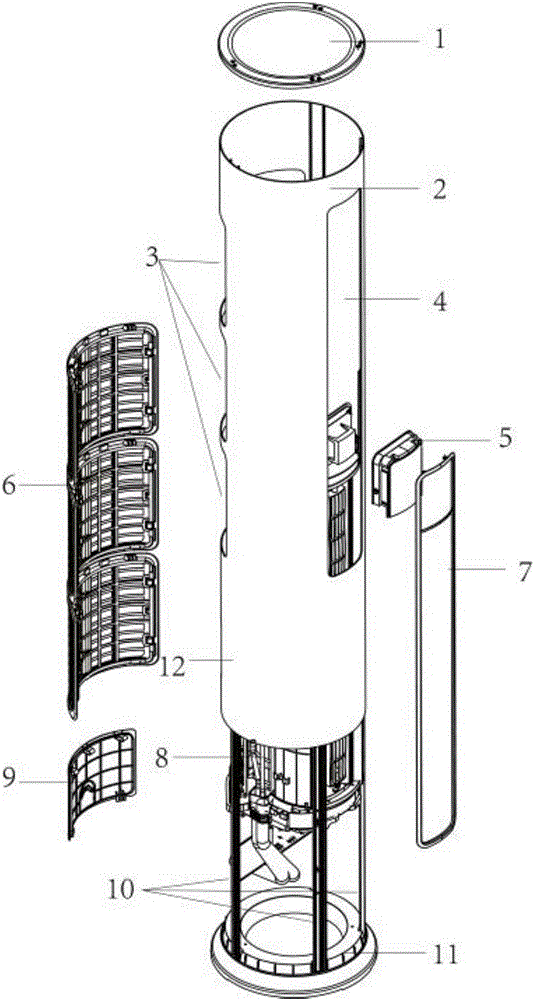

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0040] Such as Figure 1-8 As shown, the extruded vertical air conditioner of the present invention includes:

[0041] The outer shell 2, the outer shell is an integrally formed structure, which is manufactured by an integrated extrusion secondary processing molding process, and the middle part is hollow to form an inner cavity,

[0042] Its front side is provided with at least one vertical bar-shaped air outlet 4 along the height direction,

[0043] Its rear side is provided with at least one air inlet 3 along the height direction, figure 2 The illustrated embodiment is provided with three air inlets 3 from top to bottom,

[0044] Its upper and lower ends are provided with openings communicating with the inner cavity,

[0045] On the inner wall of the shell 2, there are several raised ribs 51 along the height direction, see Figure 5 , 6 , the ribs 51...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com