Tungsten carbide-yttria-stabilized zirconia composite thermal barrier coating and preparation method thereof

A technology for stabilizing zirconia and thermal barrier coatings, applied in coatings, metal material coating processes, melt spraying, etc., can solve the problem of poor coating adhesion, uneven particle distribution of thermal barrier coatings, and poor wear resistance. and other problems, to achieve the effect of improving wear resistance, low cost and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1, configure ZrOCl 2 ·8H 2 O / Y(NO 3 ) 3 ·6H 2 O mixed solution: 1500mL of mixed solution, ZrOCl 2 ·8H 2 O / Y(NO 3 ) 3 ·6H 2 The mass fraction of O is 20wt.%, Zr 4+ the Y 3+ The molar concentration ratio is 89:11.

[0042] In step 2, excessive ammonia water is added dropwise to the mixed solution in step 1 and continuously stirred to form a white precipitate, and the concentration of ammonia water is 30%.

[0043] Step 3, add a certain amount of PVA aqueous solution to the solution in step 2, wherein the concentration of PVA is 5%, and the addition amount is 200mL.

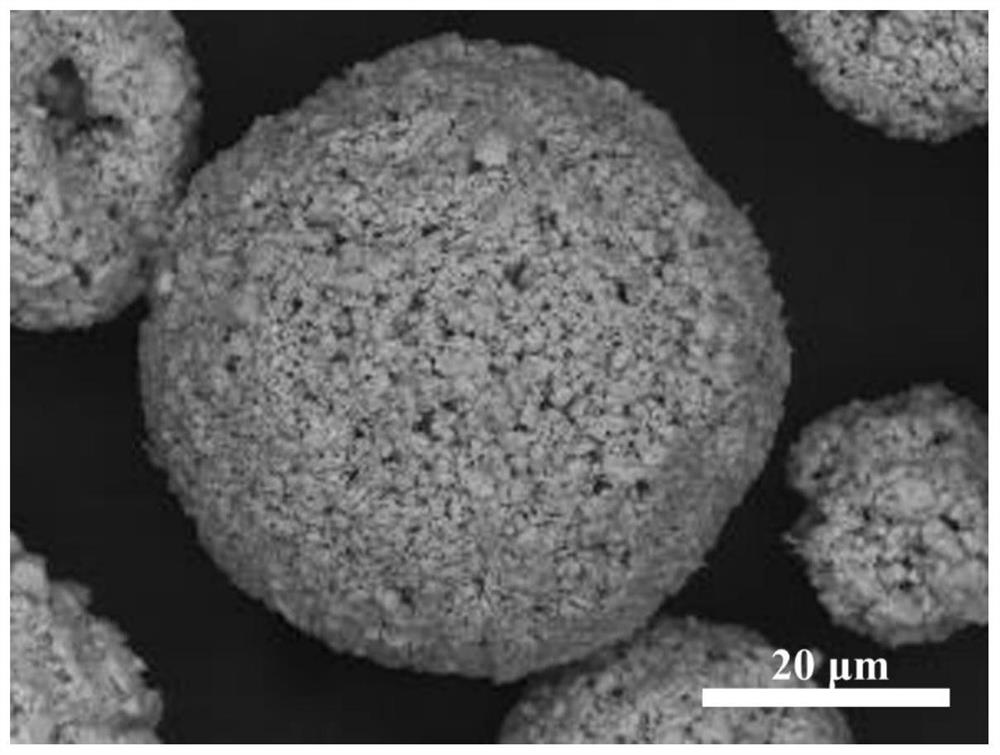

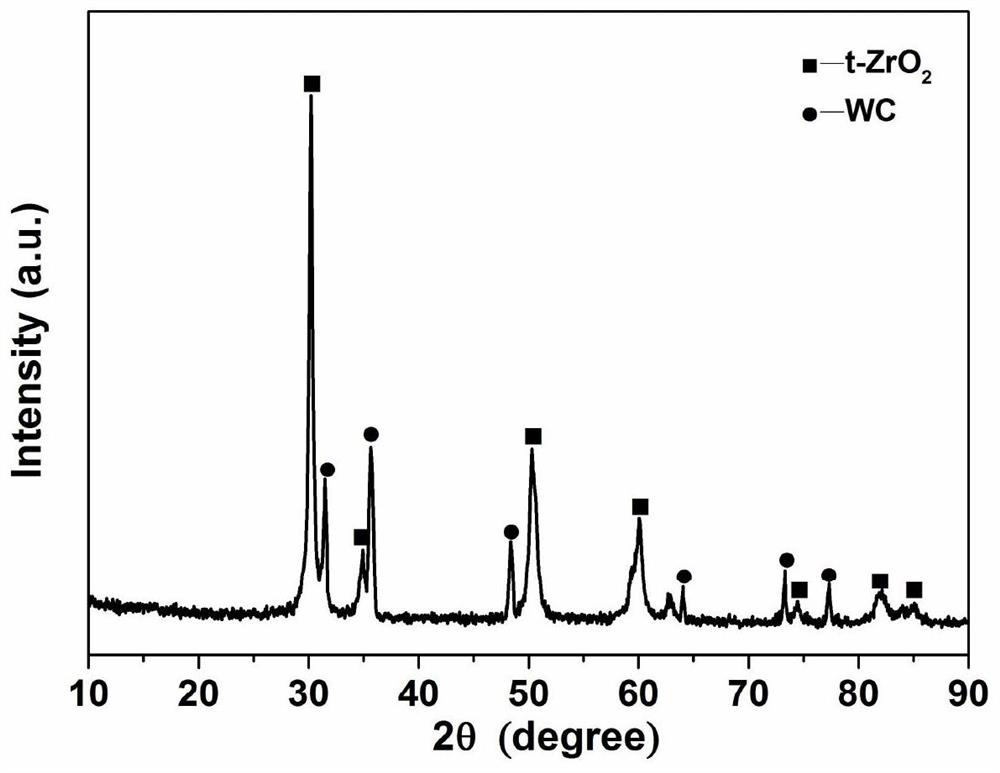

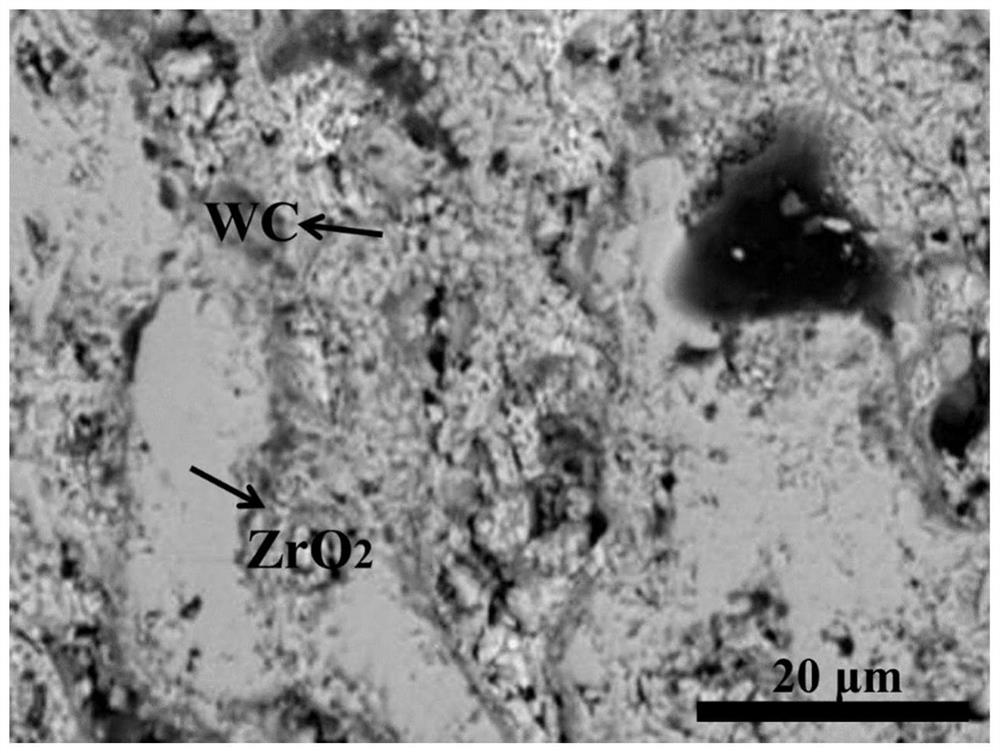

[0044] Step 4, add a certain amount of nanoscale WC particles to the mixed solution of step 3, the particle diameter is 100nm, the mass fraction of adding WC particles accounts for ZrO 2 10wt.% of coating.

[0045] In step 5, the mixture in step 4 is placed on a roller ball mill for ball milling; the speed of the roller ball mill is 40r / min, and the working time is 48h.

[0046] Step 6, gra...

Embodiment 2

[0049] Step 1, configure ZrOCl 2 ·8H 2 O / Y(NO 3 ) 3 ·6H 2 O mixed solution; the volume of mixed solution is 1500mL, ZrOCl 2 ·8H 2 O / Y(NO 3 ) 3 ·6H 2 The mass fraction of O is 60wt.%, Zr 4+ the Y 3+ The molar concentration ratio is 97:3.

[0050] In step 2, excessive ammonia water is added dropwise to the mixed solution in step 1 and continuously stirred to form a white precipitate, and the concentration of ammonia water is 50%.

[0051] Step 3, add a certain amount of PVA aqueous solution to the solution in step 2, wherein the concentration of PVA is 10%, and the added amount is 300mL.

[0052] Step 4, add a certain amount of nanoscale WC particles to the mixed solution of step 3, the particle size range is 300nm, and the mass fraction of the added WC particles accounts for ZrO 2 30wt.% of the coating.

[0053] In step 5, the mixture in step 4 is placed on a roller ball mill for ball milling; the speed of the roller ball mill is 80r / min, and the working time is 24...

Embodiment 3

[0057] Step 1, configure ZrOCl 2 ·8H 2 O / Y(NO 3 ) 3 ·6H 2 O mixed solution; the volume of mixed solution is 1500mL, ZrOCl 2 ·8H 2 O / Y(NO 3 ) 3 ·6H 2 The mass fraction of O is 30wt.%, Zr 4+ the Y 3+ The molar concentration ratio is 95:5.

[0058] In step 2, excess ammonia water is added dropwise to the mixed solution in step 1 and continuously stirred to form a white precipitate, and the concentration of ammonia water is 40%.

[0059] Step 3, add a certain amount of PVA aqueous solution to the solution in step 2, wherein the concentration of PVA is 8%, and the addition amount is 250mL.

[0060] Step 4, add a certain amount of nanoscale WC particles to the mixed solution of step 3, the particle size range is 200nm, and the mass fraction of the added WC particles accounts for ZrO 2 20wt.% of the coating.

[0061] In step 5, the mixture in step 4 is placed on a roller ball mill for ball milling; the speed of the roller ball mill is 60r / min, and the working time is 36h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com