Rapid cooling furnace body of a horizontal diffusion furnace

A technology of diffusion furnace and cooling furnace, applied in furnace, furnace cooling, furnace components and other directions, can solve the problems of difficult to guarantee film quality, poor temperature repeatability in furnace, slow natural cooling rate, etc. Influence of semiconductor parts, effect of stable and reliable working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

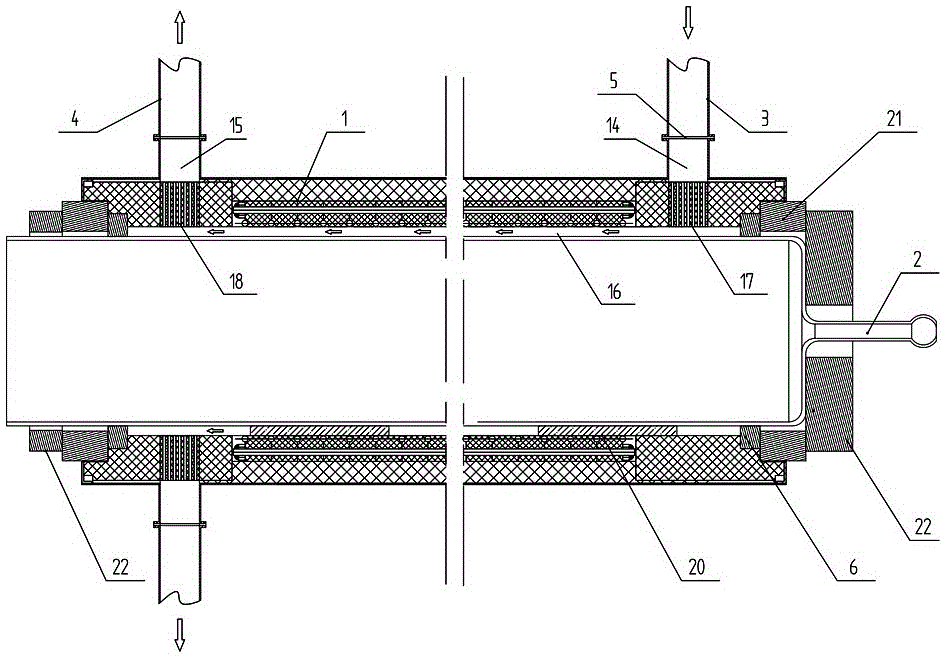

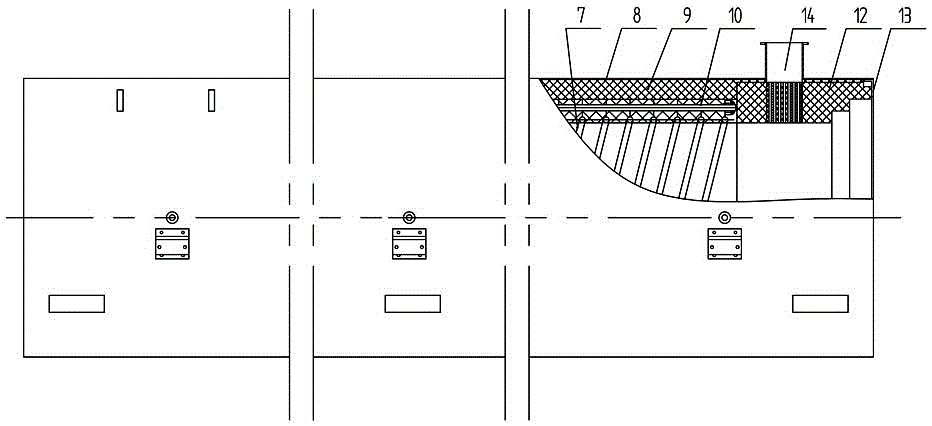

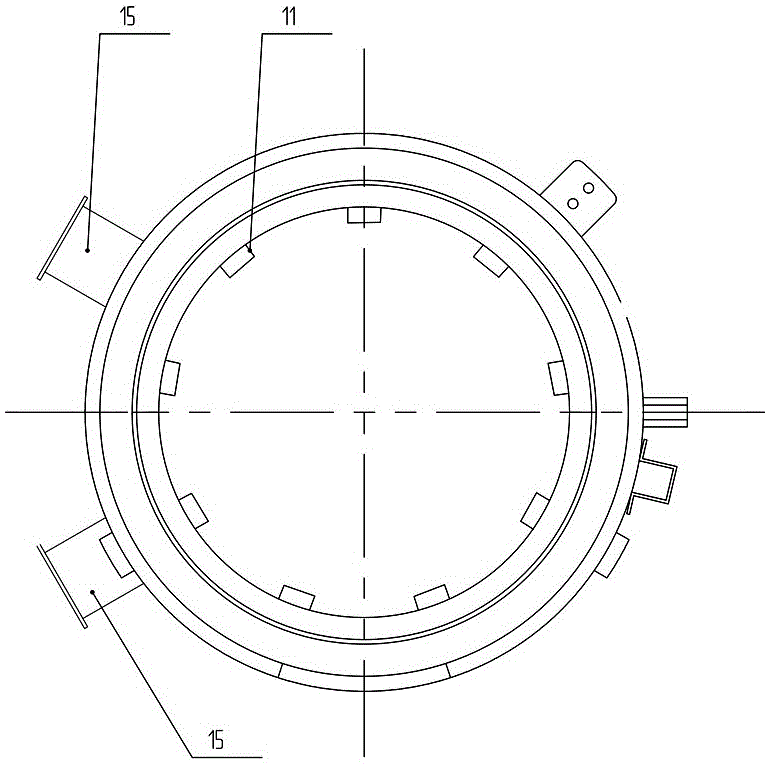

[0027] Figure 1 to Figure 5 A kind of embodiment of the fast cooling furnace body of the horizontal diffusion furnace of the present invention is shown, the fast cooling furnace body of the horizontal diffusion furnace includes a reaction quartz tube 2 and a resistance furnace body 1 sleeved outside the reaction quartz tube 2, and the reaction quartz Between the outer wall of the tube 2 and the inner wall of the resistance furnace body 1 there is a columnar gap with an annular cross section, and both ends of the columnar gap are provided with seals 6 so that the columnar gap forms a closed ventilation channel 16, and the resistance furnace body 1 is provided with a The ventilation channel 16 has an air inlet 14 for supplying air and an air outlet 15 for discharging hot air in the ventilation channel 16 . When the process reaches the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com