Multi-bonding point high-load inclined pushing-type loading device

A loading device and high-load technology, which is applied in the direction of measuring devices, instruments, and mechanical parts testing, and can solve problems such as increased test installation heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be further described in conjunction with the drawings and specific embodiments.

[0022] Hereinafter, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

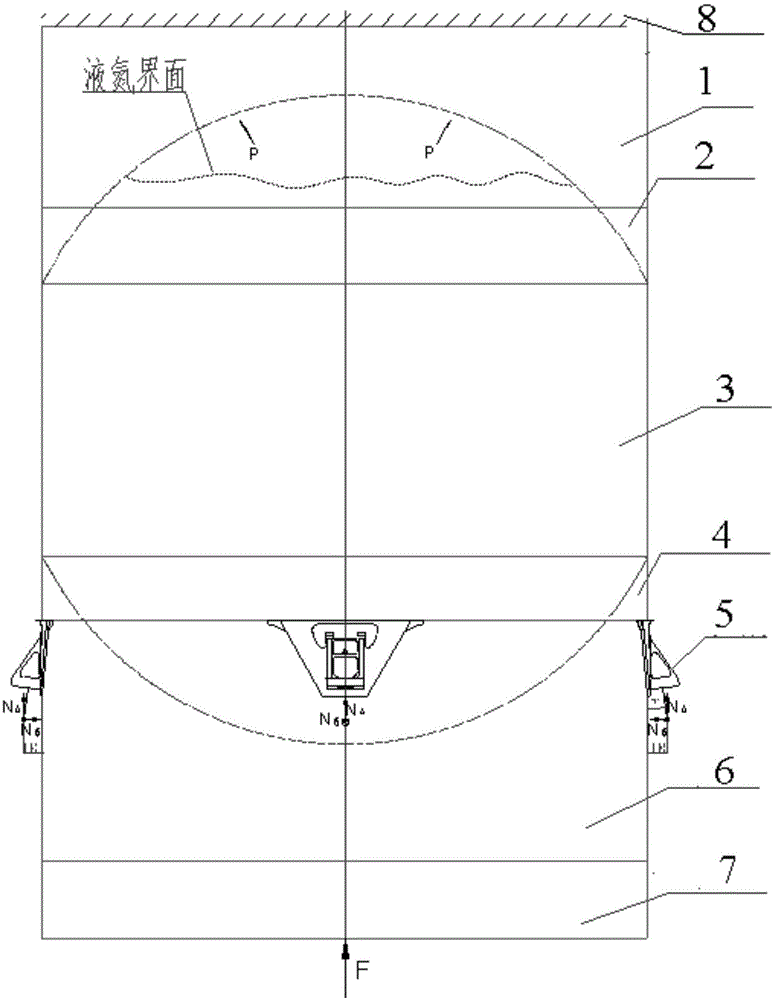

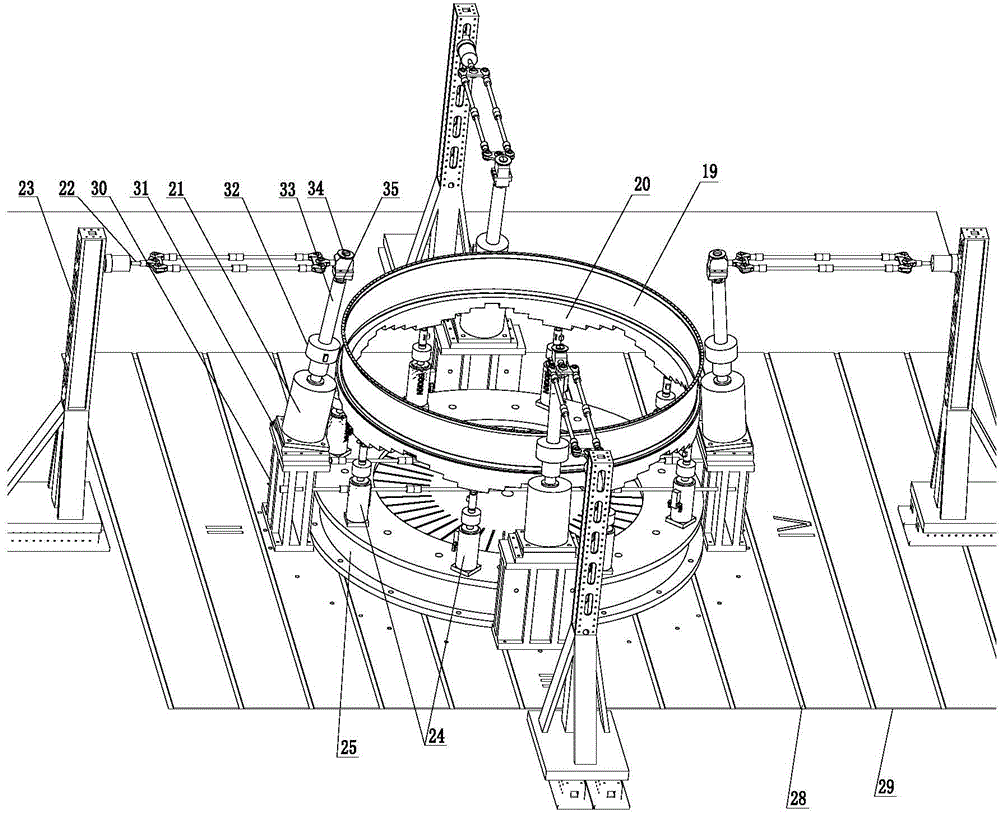

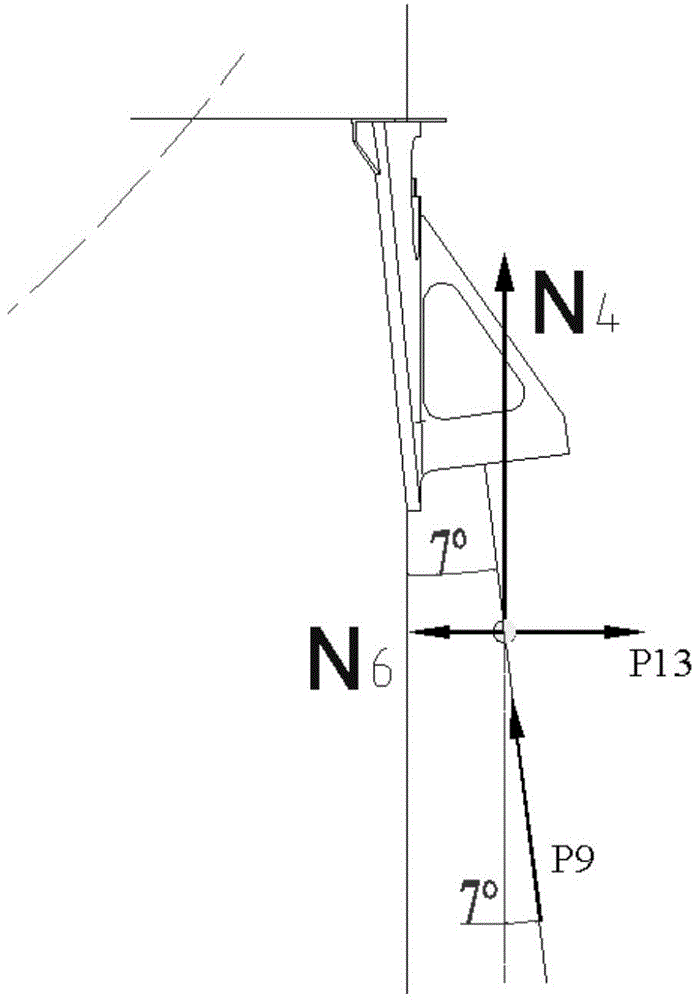

[0023] According to the load application requirements in the test task, from figure 1 It can be seen from the figure that the test loads include the pressure load P of the air pillow of the first-stage oxygen tank 3, the axial compressive load F of the rear end surface section of the front short shell 7 of the first-stage hydrogen tank, and the concentrated load N on the four binding supports 5 4 and N 6 . In the test, the axial compression load F and the concentrated force load at the binding point are realized by a 16-channel automatic coordinated loading system, and the load is measured by a load cell. The load in the task book is converted into the load applied at each loading point, and the appropriate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com