Method of determining silicon content in ferro-silico aluminum through silico-molybdenum blue colorimetric method

A silicon-molybdenum blue colorimetric method and a technology of silicon content, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of slow operation and long process, achieve the effect of shortening the operation process, accurate and reliable data, and reducing labor expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The above-mentioned and other technical features and advantages of the present invention will be described in more detail below in conjunction with the embodiments.

[0025] 1. Method summary:

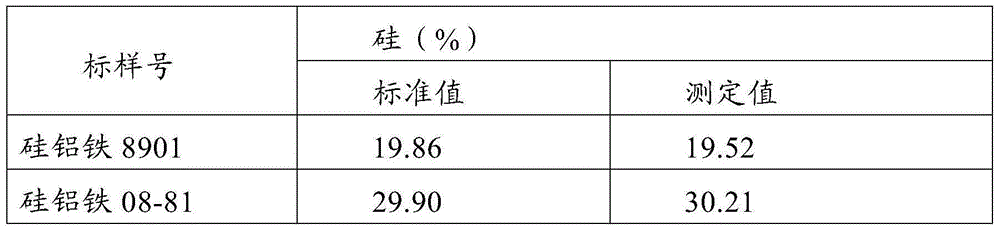

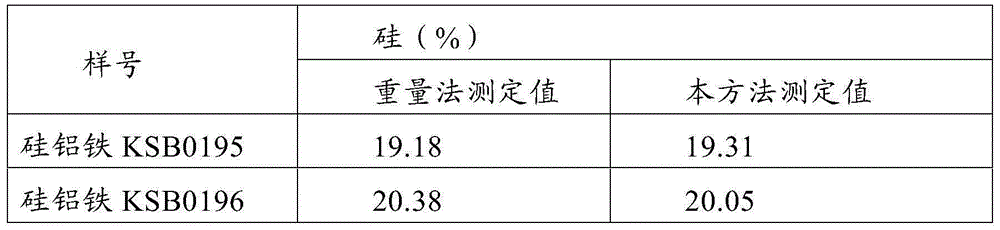

[0026] This method uses sodium hydroxide solution to dissolve most of the samples, then add dilute hydrochloric acid-nitric acid to dissolve the remaining samples, heat until the samples are completely dissolved, cool to room temperature, transfer to a 250mL volumetric flask, divide 10mL into a 100mL volumetric flask, Ammonium molybdate is added to form silicon molybdenum yellow, oxalic acid is added to mask interfering elements, ferrous ammonium sulfate is added to form silicon molybdenum blue, and the absorbance of the solution is measured with a spectrophotometer. The standard sample with the same species and similar content along with the sample is converted to the sample content value.

[0027] 2. Reagents:

[0028] 2.1 Nitric acid (density 1.42g / mL)

[0029] 2.2 Hydroch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com