Control system of 3D printer

A 3D printer and control system technology, applied in the direction of digital output to printing unit, energy-saving calculation, climate sustainability, etc., can solve the problems of affecting printing effect, unfavorable heat dissipation of devices, high cost, etc., to achieve human-computer interaction function, reduce The cost of board making and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

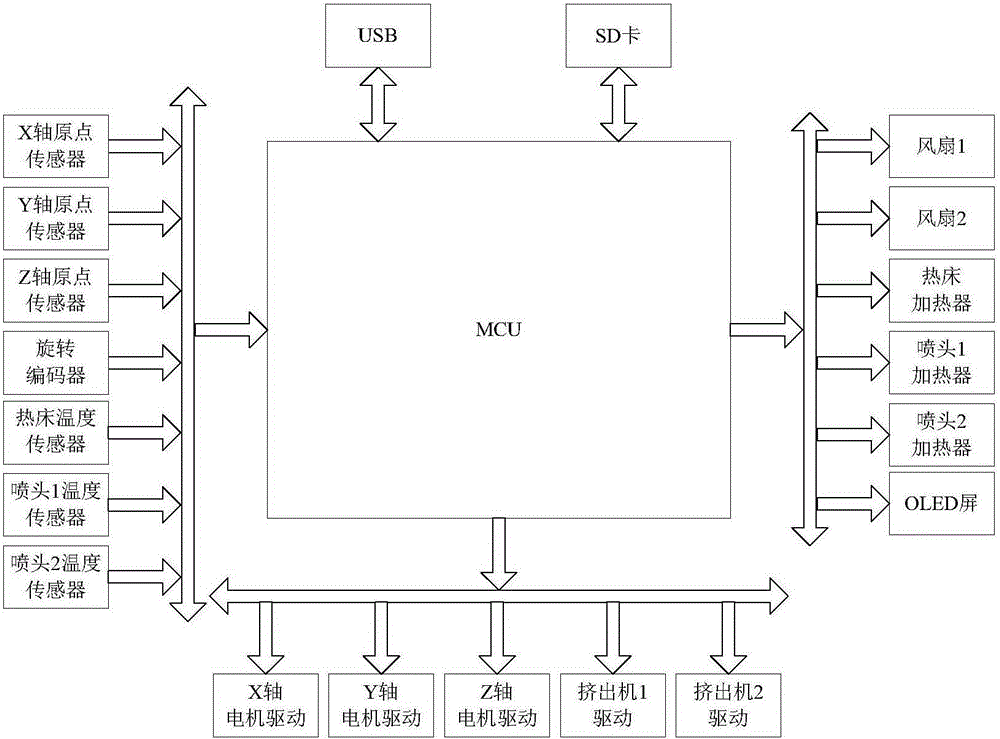

[0042] figure 1 Shown is the hardware block diagram of the 3D printer control system of the present invention, including the micro control unit MCU, the micro control unit MCU is respectively connected with USB interface, SD card interface, X-axis origin sensor, Y-axis origin sensor, Z-axis origin sensor, rotary encoder Sensor, hot bed temperature sensor, nozzle 1 temperature sensor (namely the first nozzle temperature sensor), nozzle 2 temperature sensor (namely the second nozzle temperature sensor), X-axis motor drive, Y-axis motor drive, Z-axis motor drive, extrusion Machine 1 drive (that is, the first extruder drive), extruder 2 drive (that is, the second extruder drive), fan 1 (that is, the first fan), fan 2 (that is, the second fan), hot bed heater , Extruder 1 heater (namely the first extruder heater), extruder 2 heater (i.e. the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com