Marine waterproof cable

A waterproof cable and marine technology, which is applied in the field of circuits, can solve the problems of short service life, poor waterproof effect, and influence on signal transmission, and achieve the effect of economical and practical, simple structure, compact and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

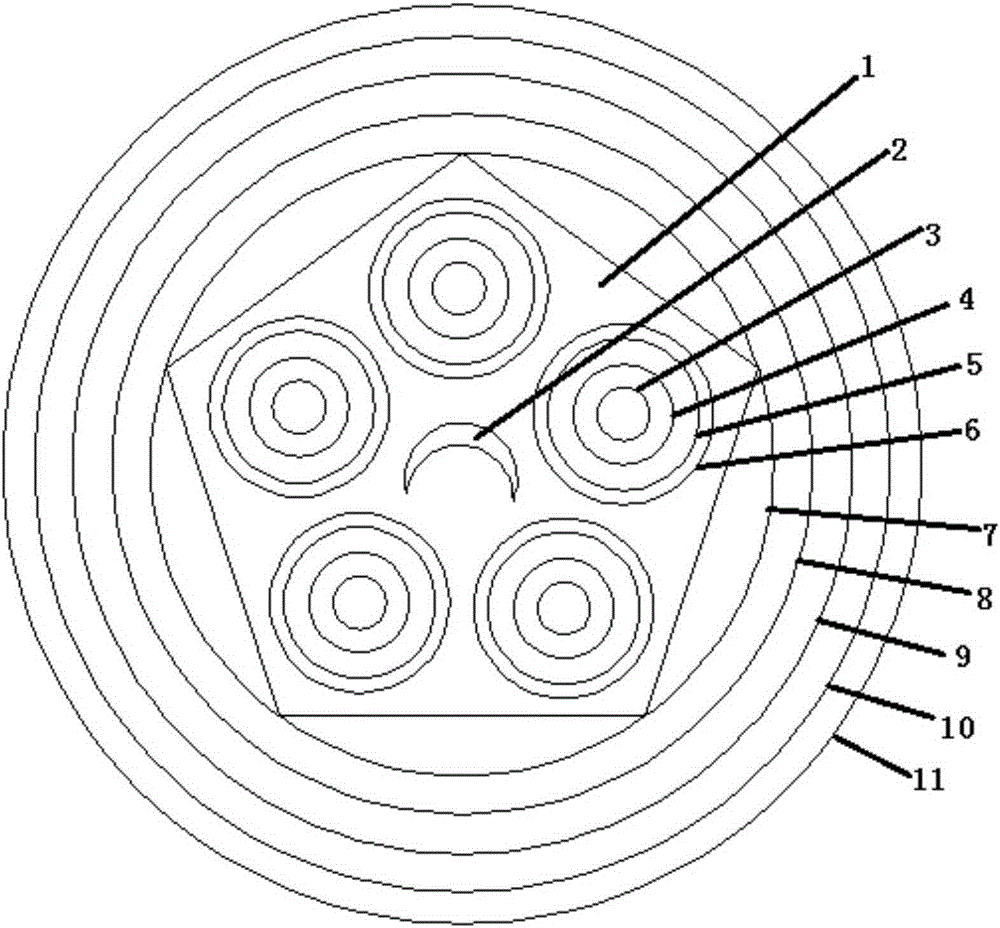

[0008] like figure 1 As shown, a marine waterproof cable includes a regular pentagonal rubber cylinder 1, a meniscus-shaped through hole 2 is opened in the center of the regular pentagonal rubber cylinder 1, and a meniscus-shaped through-hole 2 is opened around the meniscus-shaped through-hole 2. There are five circular holes, and a wire core is placed in each circular hole. The wire core includes a conductor 3, and the conductor 3 is twisted by tinned annealed copper strands. The outside is sequentially covered with a cross-linked polyethylene insulating layer 4, an aluminum-magnesium alloy wire braided shielding layer 5 and a waterproof canvas wrapping layer 6, and the outside of the regular pentagonal rubber cylinder 1 is sequentially covered with a nano-silicon waterproof rubber filling layer 17. Polyester film wrapping layer 8, nano silicon waterproof glue filling 29, aluminum tape interlocking armor layer 10 and chlorosulfonated polyethylene outer sheath 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com