Aircraft instrument magnet steel

A technology for aircraft instrumentation and magnetic steel, applied in the direction of magnetic materials, magnetic objects, permanent magnets, etc., can solve the problems affecting product performance, magnetic performance gap, inconsistent magnetization direction and internal columnar crystal direction, etc., to improve product performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

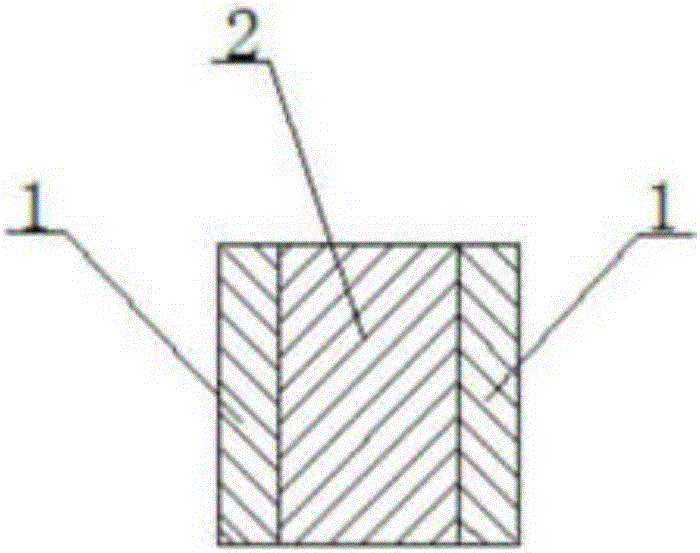

[0010] figure 1 It is an embodiment of the present invention. The aircraft instrument magnetic steel provided in this embodiment includes an AlNiCo magnetic steel body 2 and a lining iron 1. The cross section of the AlNiCo magnetic steel body 2 is in the shape of a ring runway, and the number of the lining iron 1 is 1. 4 pieces, and are symmetrically pasted on the two side planes of the AlNiCo magnet steel body 2 to form a cylindrical structure.

[0011] Since the cross-section of the AlNiCo magnet body 2 is in the shape of an annular racetrack, the direction of the columnar crystals is parallel to the two straight sides of the cross-section, and can be positioned by the straight sides during the magnetization orientation process of heat treatment, so as to achieve the magnetization direction and the columnar crystallographic direction. Completely coincident to achieve maximum magnetization effect and improve product performance.

[0012] As a preference of this embodiment, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com