Automatic row alignment device of root-tuber crop harvesting machine

A technology for harvesting machinery and rhizomes, which is applied in the field of automatic counter-moving devices for harvesting machinery for rhizomes, can solve the problems of less research on new structures and new theories, poor adaptability, and retention, so as to improve accuracy and response sensitivity, reduce The effect of skipping and digging, improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

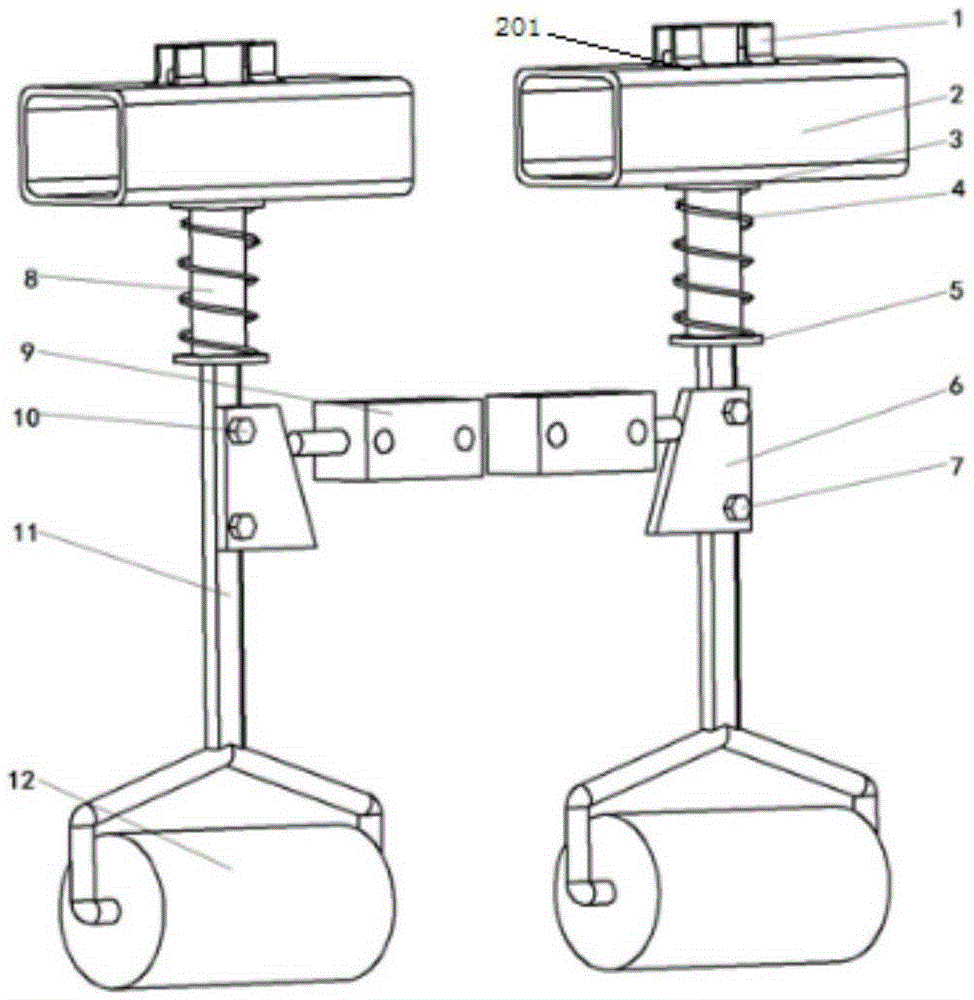

[0024] see figure 1 , in a preferred embodiment of the present invention, a kind of rhizome crops harvesting machinery automatic rowing device comprises tractor 14, rowing mechanism 16, digging mechanism 17, ground wheel 18, traction mechanism 19, piston rod 20, oil pump 15 And frame 21.

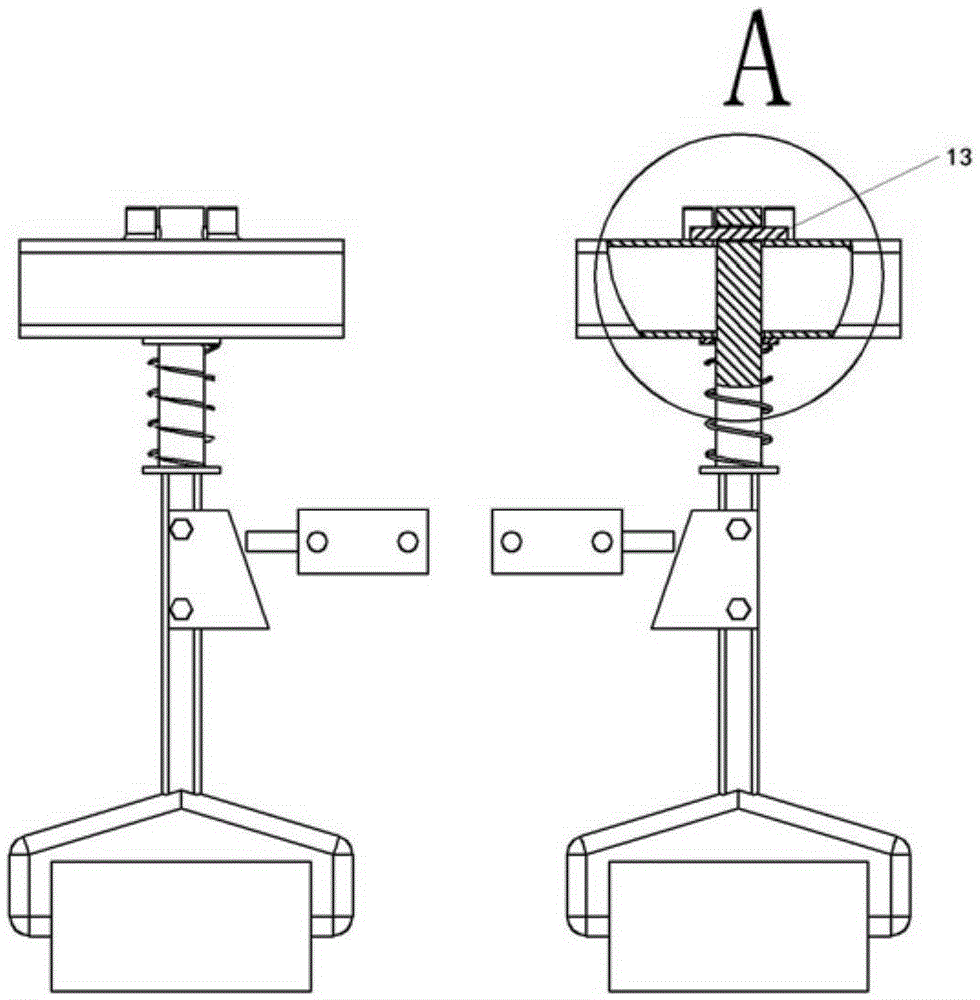

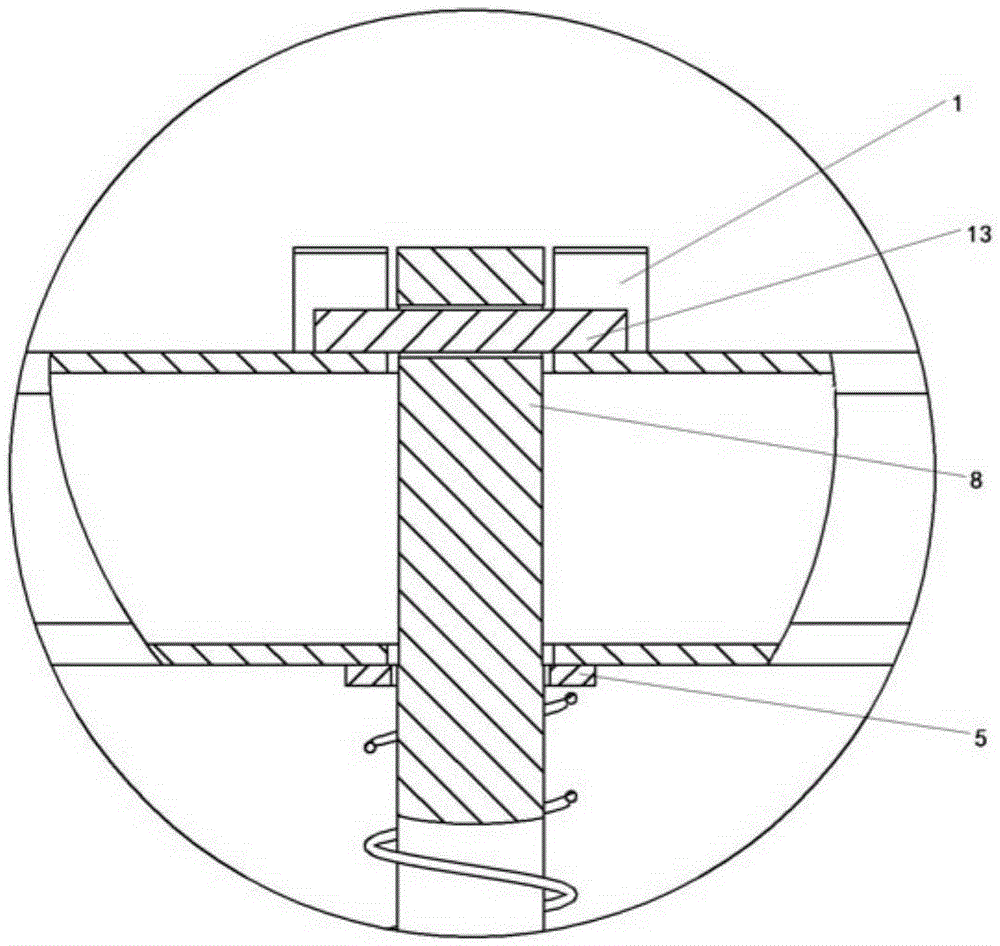

[0025] Such as figure 1 , figure 2 and image 3 As shown, the pairing mechanism 16 includes a fixed frame 1, a support frame 2, an upper fixed seat 3, a spring 4, a lower fixed seat 5, a wedge 6, a lower bolt 7, a round rod 8, and two-position two-way manual reversing Valve 9, upper bolt 10, straight rod 11, profiling cylinder 12 and round pin 13, a circular through hole 201 is provided in the middle of the support frame 2, and the fixed frame 1 and the upper fixed seat 3 are connected to the support frame through the circular through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com