Small automatic honey pill machine

A fully automatic, honey pill machine technology, applied in the direction of making medicines into special physical or taking forms of devices, etc., can solve the problems of inconvenient maintenance and miniaturization, unfavorable equipment handling and manufacturing, and complicated honey pill machines. To achieve the effect of simple structure, uniform shape and good functional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

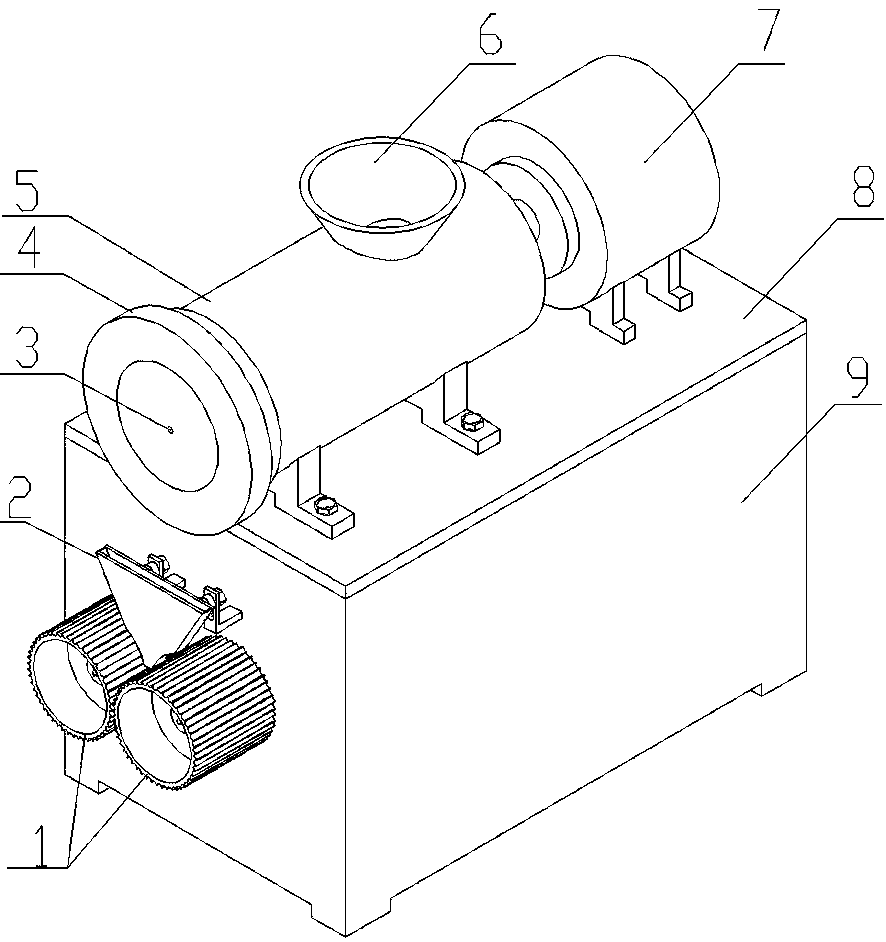

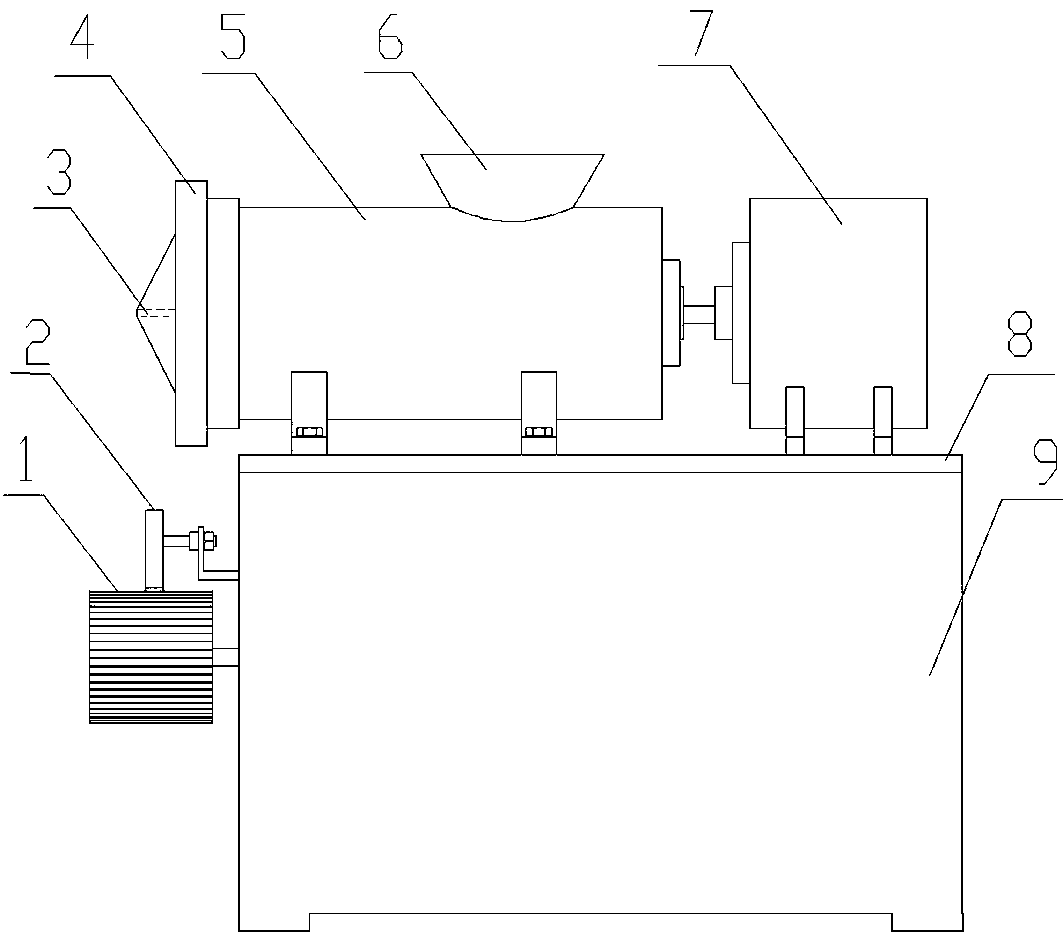

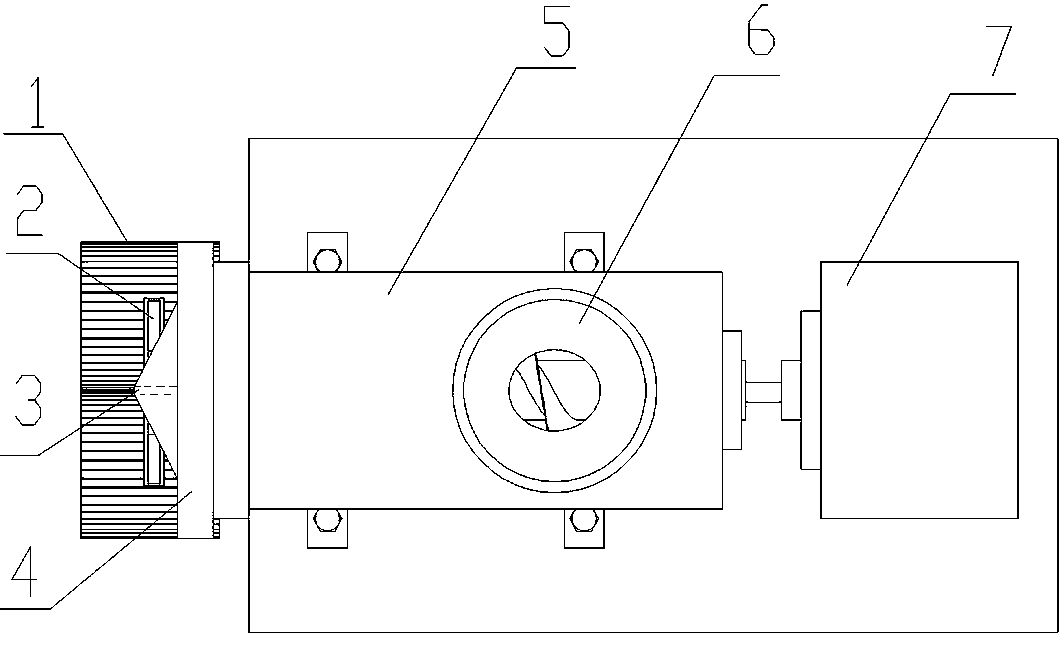

[0038] Such as figure 1 and Figure 8 Shown, a kind of small-sized full-automatic honey pill machine comprises a frame and a strip making device and a strip-cutting pill-rubbing device arranged on the frame; the strip-cutting pill-rubbing device includes a first motor 11, a transmission mechanism and two The tooth groove is semicircular and the tooth top circle is tangent to the working gear 1. When working, the first motor 11 drives the two working gears 1 to perform intermittent reverse rotation through the transmission mechanism. , the first motor 11 drives one of the working gears 1 to move in the axial direction and reset through the transmission mechanism; The mixed raw material is made into strips by the strip making mechanism, and then enters the side where the two working gears 1 bite and is cut into a small section by the gears. In the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com