Filter plate assembly used in filter press

A filter press and filter plate technology, applied in the field of filter press parts, can solve the problems of small water guide cross-sectional area, large resistance, small filtration area, etc., and achieve the effect of fast flow rate, small resistance and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

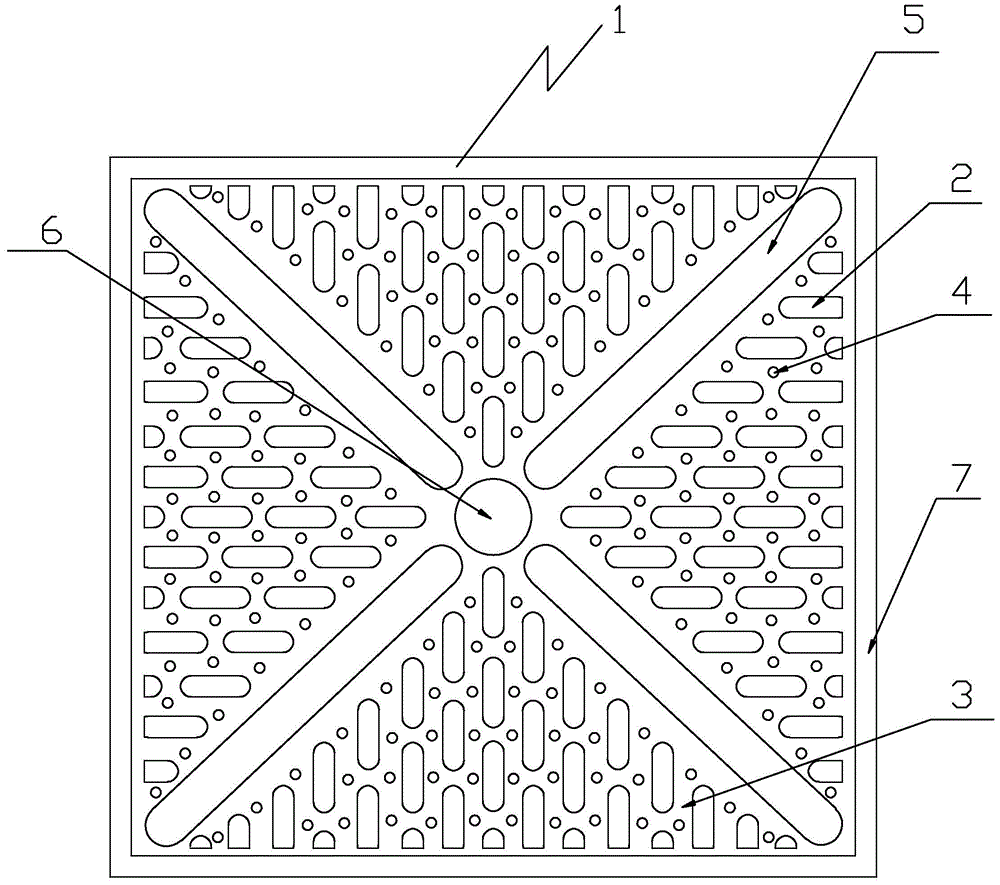

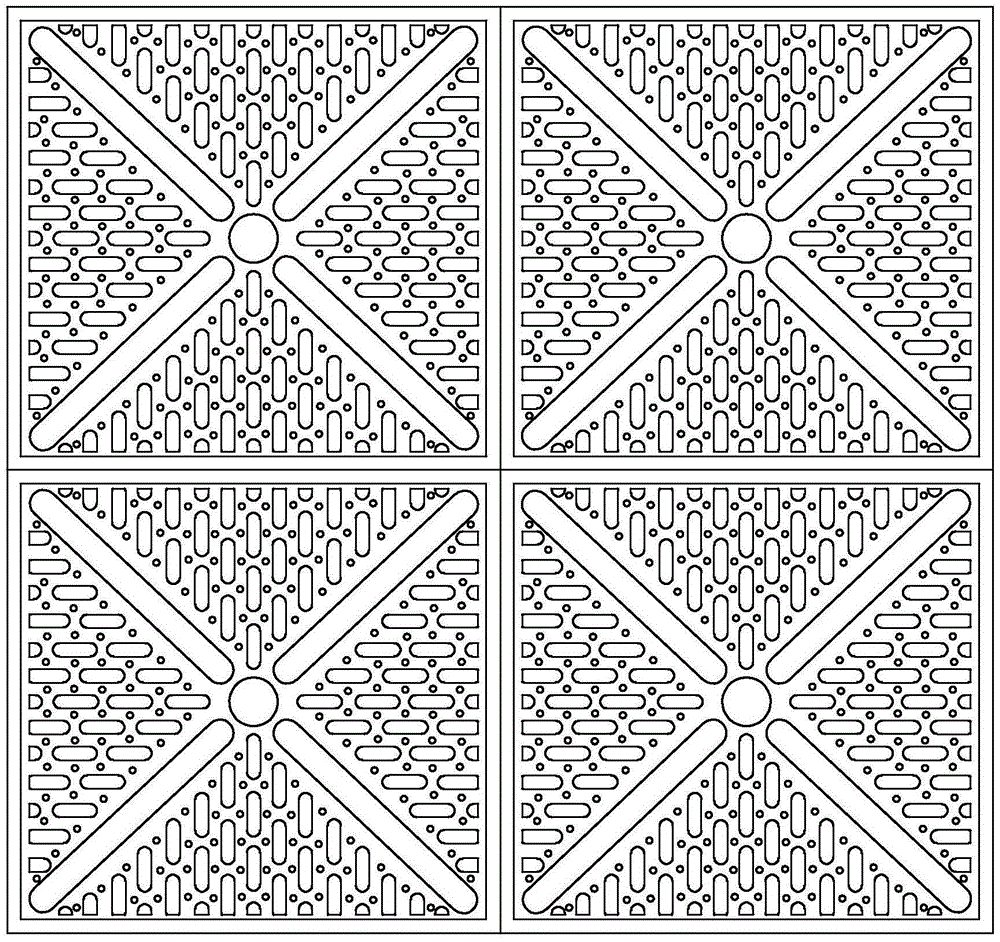

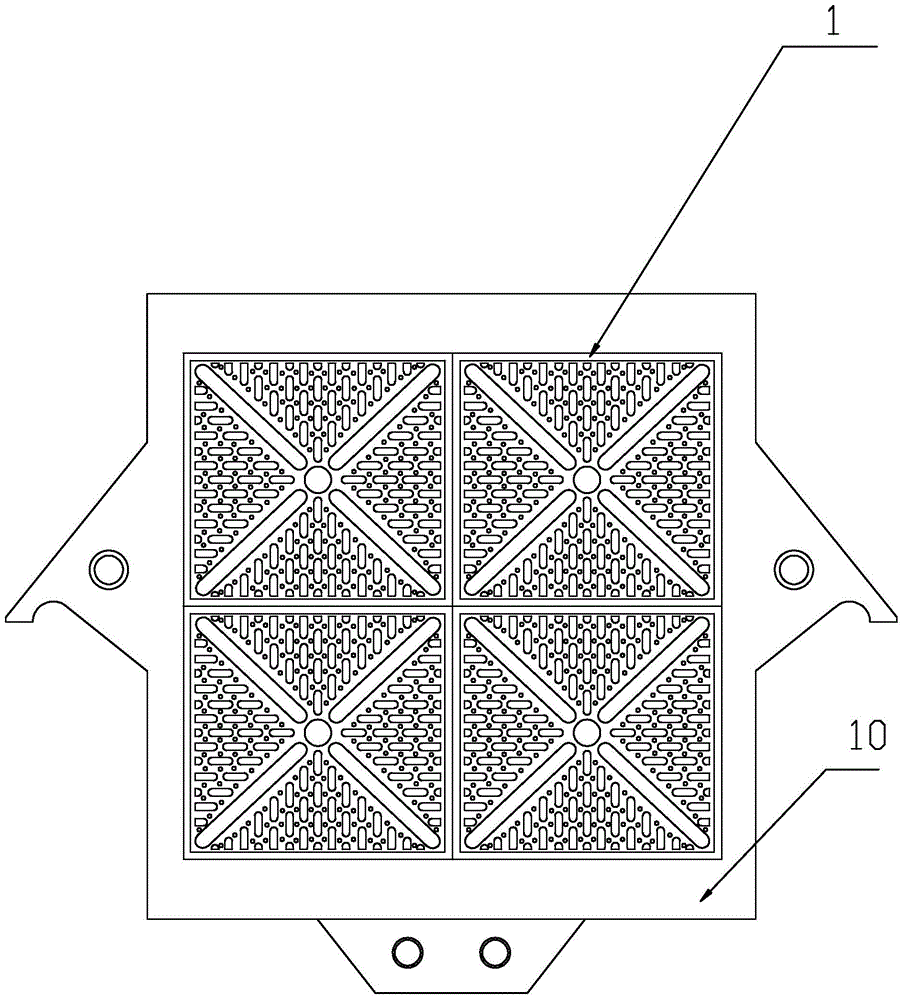

[0027] As shown in the figure, the present invention provides a filter plate assembly for a filter press, which includes a filter plate body 1 and a square protrusion 7 arranged on the edge of the filter plate body 1, and the upper surface of the filter plate body 1 is evenly distributed with several a protrusion 2, the protrusion 2 is located in the square protrusion 7, a water guide groove 3 is formed between the protrusion 2 and the protrusion 2, and a plurality of filter holes 4 are evenly distributed in the water guide groove 3, The projection of the projection 2 on the filter plate body 1 is waist-shaped. The advantage of the present invention is that the projections of the projections 2 in the prior art on the filter plate body are all circular, so that the projection 2 occupies a large area. The larger the protrusion 2 is, the larger th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com