Filter bag dust remover with self-circulating ash removal device

A technology of dust cleaning device and dust collector, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and separation of dispersed particles. Induced fan load and other issues to achieve the effect of ensuring the blowing effect, reliable operation, and prolonging the life of the filter bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

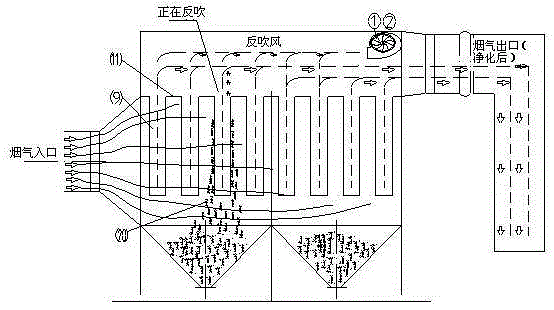

[0038] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

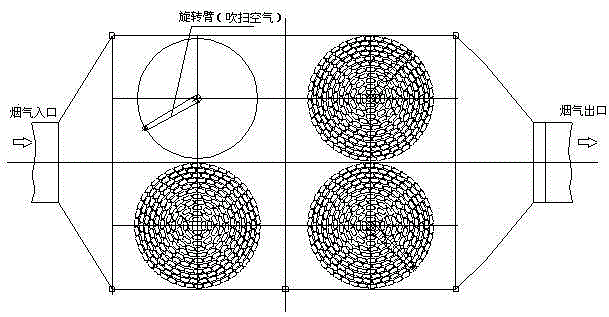

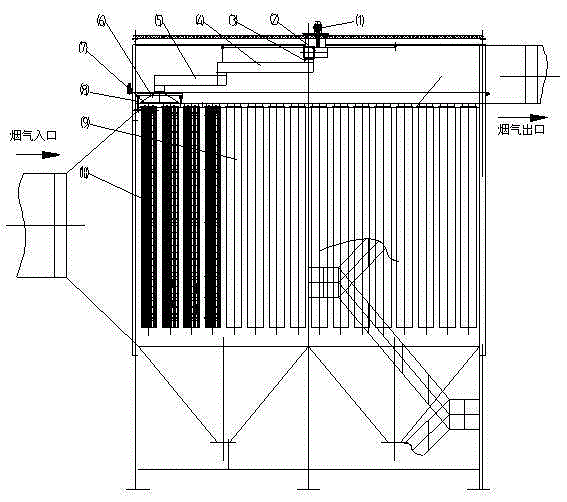

[0039] The self-circulation dust removal filter bag dust collector of the present invention includes a basic support, an air flow uniform distribution and flow guide device, a filter bag room, a clean air room, filter components (filter bags, bag cages, flower plates, etc.), and a self-circulation dust removal system. , ash hopper, electrical control system, insulation layer, platform, stairs, and a pre-painted ash system.

[0040] See image 3 , Schematic diagram of the working principle of the self-circulating dust-cleaning filter bag filter.

[0041] Among the figure: motor 1, centrifugal fan 2, filter bag 9, flower plate 11, dust 20.

[0042]The dust-laden flue gas from the boiler air preheater enters the bag filter through the flue at the flue gas inlet, and under the negative pressure of the induced draft fan, the flue gas enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com