Slurry recycling and stirring tank

A recovery tank and mixing tank technology, applied in the high-density fiberboard production line and fiber slab field, can solve the problems of lack of reliability of the equipment, and achieve the effect of simple structure and stable and reliable operation of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

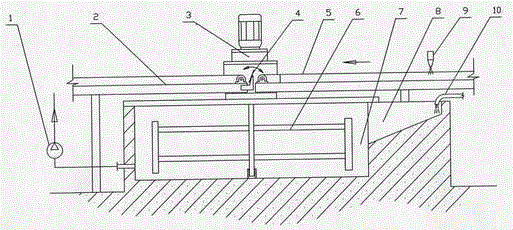

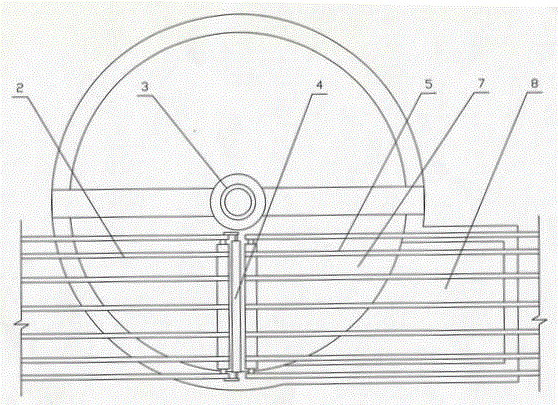

[0008] The embodiment is described in detail in conjunction with the above drawings. The electromagnetic flipper 4 is arranged in the middle of the slab conveying platform 2 and another slab conveying platform 5, and the slab conveying platform 2 and the other slab conveying platform 5 pass through the support fixed, the bottom of the electromagnetic flapper is provided with a slurry recovery tank 7, a vertical agitator 6 is arranged in the slurry recovery tank, and a coupling is used between the stirring reduction motor 3 and the agitator, and the slurry The profile of the material recovery tank is circular, and the front of the said slurry recovery tank is the edge-aligned slurry recovery tank 8, and the bottom of the said edge-aligned recovery tank is a square with a slanted bottom. Further, the length of the edge-aligned recovery tank extends to The lower part of the trimming spray nozzle 9 is water-cut, so as to collect the waste fiber slurry of the trimming slab, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com