Connecting technology for metals without solid solubility

A non-solid solution, metal technology, used in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of cumbersome process, uneven and discontinuous bonding interface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

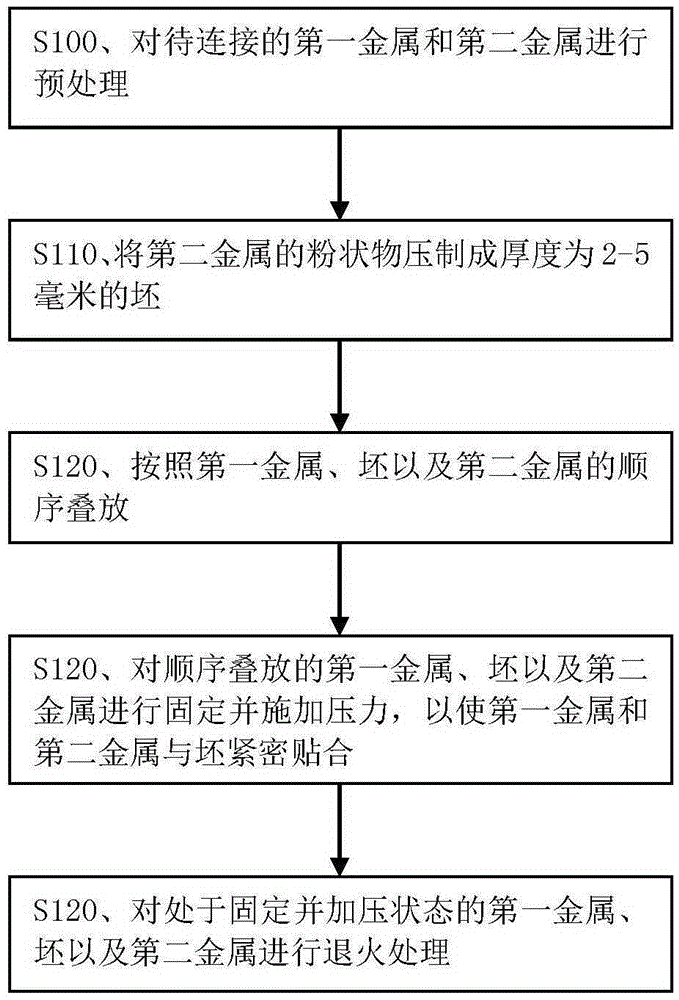

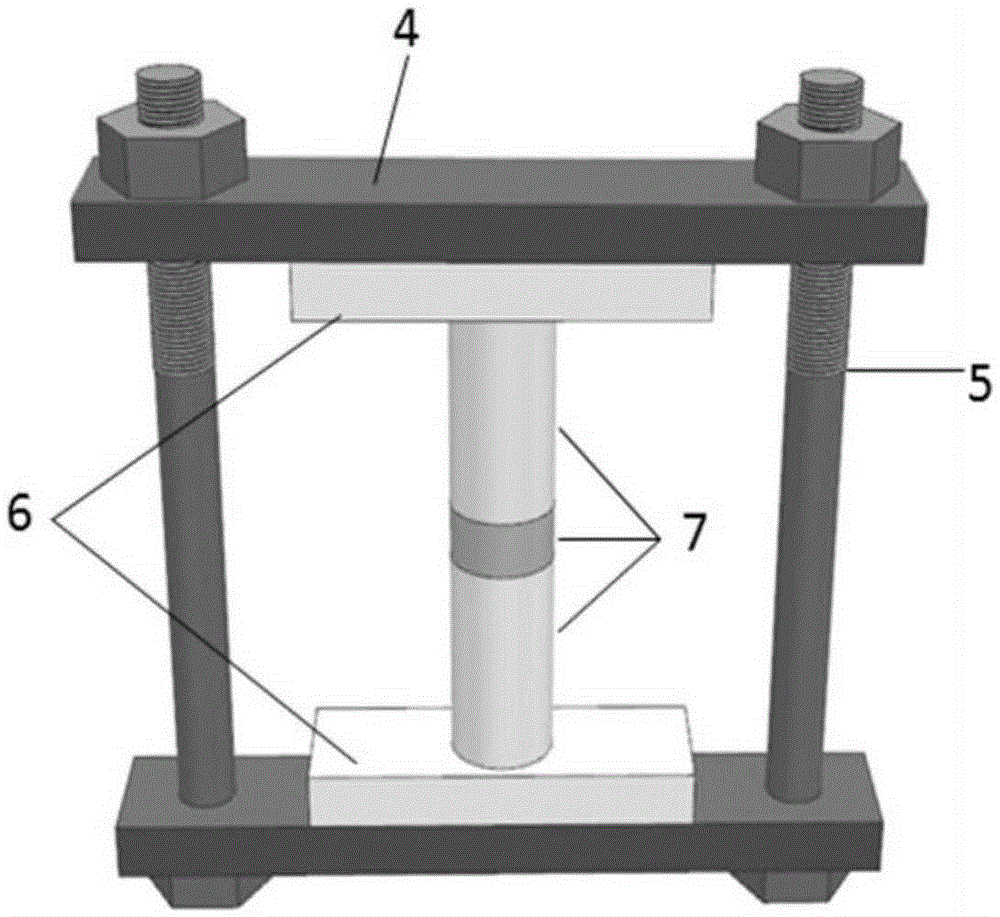

[0021] Embodiment 1. The joining process of mutually insoluble metals. The procedure of this method is as follows figure 1 shown.

[0022] figure 1 , S100. Perform pretreatment on the first metal and the second metal to be connected.

[0023] Specifically, the first metal in this embodiment may be molybdenum, the first metal may also be tungsten, the second metal may be copper, and the second metal may also be silver. That is to say, the technical solution of this embodiment can connect molybdenum and copper, molybdenum and silver, tungsten and copper, or tungsten and silver.

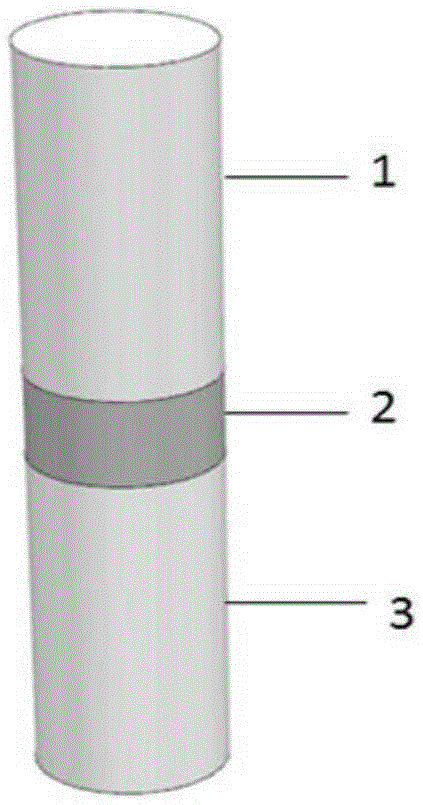

[0024] The first metal in this embodiment can be in the shape of a plate, or in the shape of an elongated rod (such as a round rod or a square rod, etc.) or block, and the second metal can be in the shape of a plate, or in an elongated shape. Rods (such as round rods or square rods, etc.) or blocks.

[0025] It should be noted that the specific shapes of the interconnected first metal and the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com