Anchor equipment and anchoring method for tension connection of partially prestressed electric poles

A prestressing and tensioning technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve problems such as quality problems, complex structures, and product scrapping, and achieve the effects of controllable product quality, simple processing technology, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

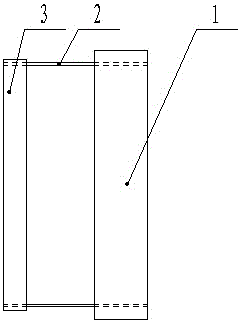

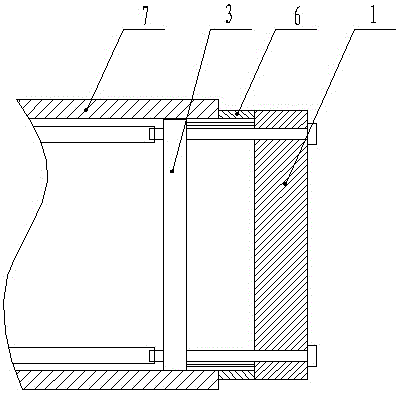

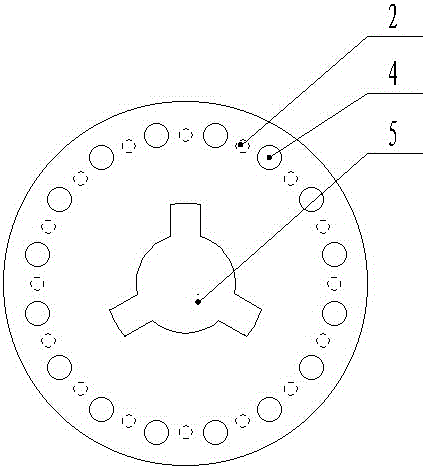

[0019] As shown in the figure, the partial prestressed pole tension connection and anchoring equipment involved in the present invention includes a main plate 1, and the material of the main plate 1 is alloy steel. In this embodiment, forged Q345 is used. One side is provided with an auxiliary disk 3, the diameter of the main disk 1 is larger than the diameter of the auxiliary disk 3 and the difference is 30mm-40mm (this embodiment takes 40mm as an example), and the thickness of the main disk 1 is 40mm-70mm (This embodiment takes 50mm as an example), the thickness of the auxiliary plate 3 is 10mm-16mm (this embodiment takes 12mm as an example), and the main plate 1 and the auxiliary plate 3 are both fixed with the main plate 1 and the auxiliary plate 3. The reinforcing rib 2 concentrically welded on the auxiliary disk 3, the length of the reinforcing rib is 80mm-150mm (this embodiment takes 100mm as an example), the main disk 1 and the auxiliary disk 3 are provided with corresp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com