High-strength plastic tray containing reinforced plastic framework insert

A high-strength plastic and reinforced plastic technology, applied in rigid containers, containers, packaging, etc., can solve the problems of bending deformation of inserted metal reinforcing members, increased cost of pallet production systems, and easy deformation of pallet bearing pavement, etc. Low cost and the effect of improving connection fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

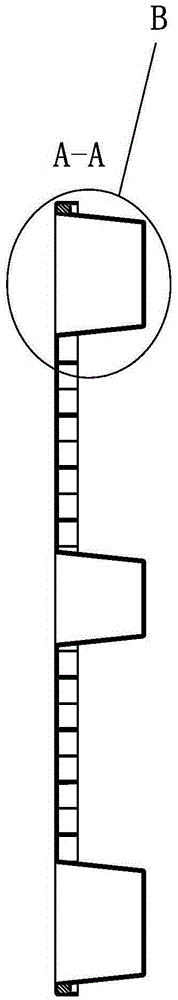

[0024] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 4 :

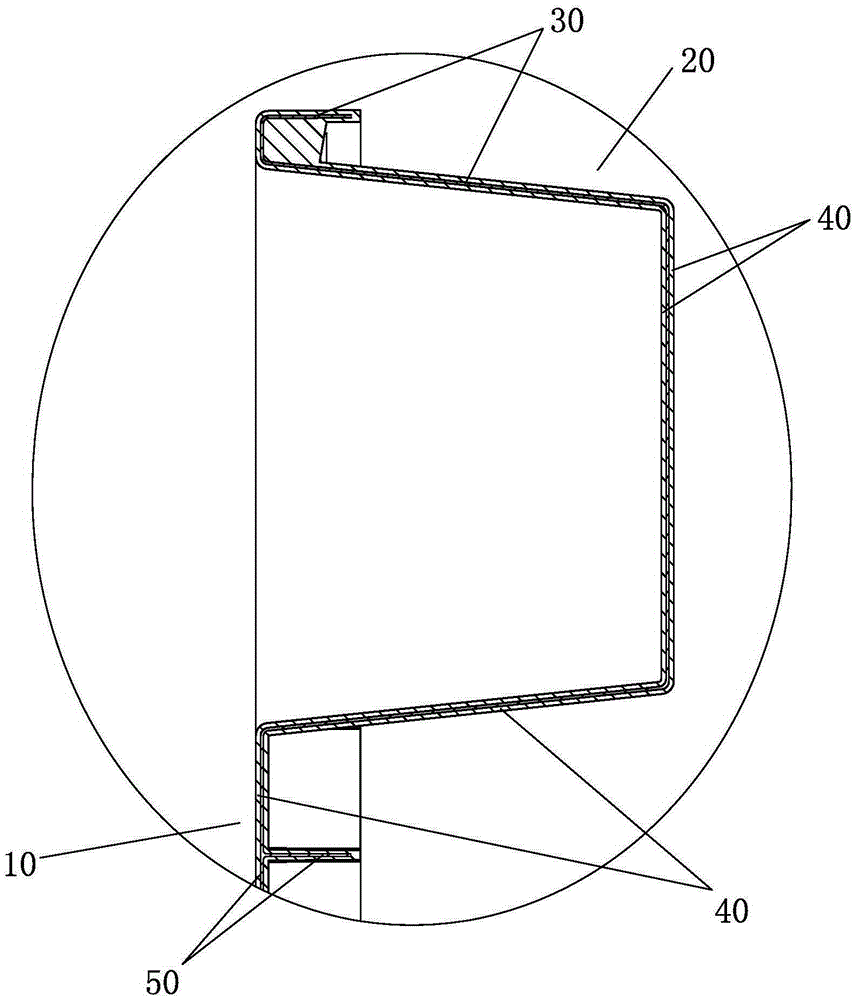

[0025] A high-strength plastic pallet containing reinforced plastic frame inserts, a layer of cladding layer 40 is injection-molded on the outer surface of the reinforced plastic frame inserts 30 adapted to the pallet load-bearing structure to form a high-strength plastic pallet containing reinforced plastic frame inserts 30 A strong plastic pallet, the hardness of the cladding layer 40 is less than that of the reinforced plastic skeleton insert 30 .

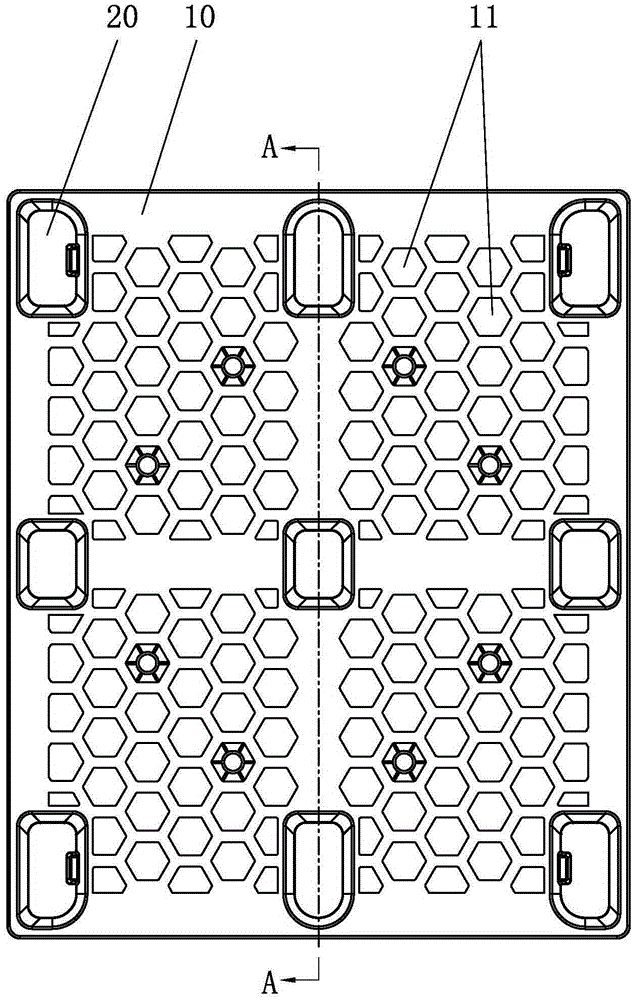

[0026] The above-mentioned high-strength plastic tray is provided with several supporting legs 20 on the lower side of the upper horizontal plate 10 to form an upper pallet, and the upper horizontal plate 10 is provided with grid-like or honeycomb-like through holes 11 .

[0027] The supporting legs 20 of the above-mentioned upper supporting board 10 are snap-connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com