Nodular cast iron with high elongation and heat treatment process of nodular cast iron

A ductile iron, high elongation technology, applied in the field of casting, can solve the problems of inability to form mass production, increase research and development costs, huge cost investment, etc., to save costs and resource investment, facilitate production and management, and improve mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A high-elongation ductile iron according to the present invention, its chemical composition includes 3.0% to 3.6% of C, 2.0% to 3.4% of Si, 0.6% to 1.5% of Mn, and 0.03% to 0.08% of Mg , 0.03% to 0.1% of rare earth element Re, and ≤2.0% of Ni, ≤1.0% of Cu, ≤0.03% of S, ≤0.15% of P, and the rest is composed of iron and impurities;

[0026] Its Brinell hardness is 170-230;

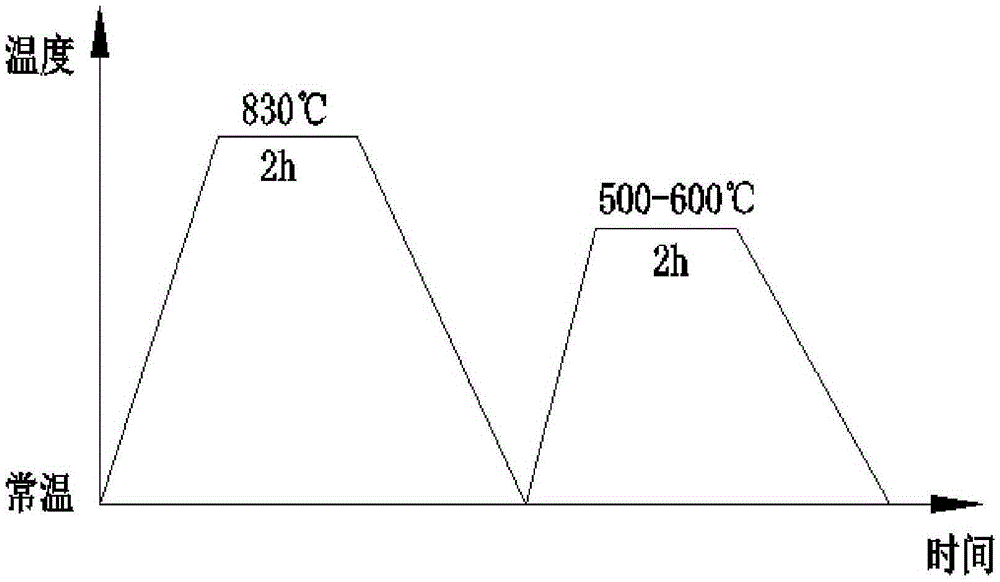

[0027] Its casting process includes smelting, casting, normalizing and tempering. In the smelting step, the iron raw material is smelted at high temperature to make it into a molten state. When the temperature of the molten metal reaches 1420-1440°C, ferrosilicon, ferromanganese, Copper; when the temperature of the molten metal reaches 1430-1450°C, it is taken out of the furnace, treated with rare earth ferrosilicon-magnesium alloy for spheroidization, pours a triangular sample, checks the spheroidization effect, and can be poured if the spheroidization is good; The sand casting process casts 10 cyli...

Embodiment 2

[0035]A high-elongation ductile iron according to the present invention, its chemical composition includes 3.0% to 3.5% of C, 2.1% to 2.4% of Si, 0.6% to 1.5% of Mn, and 0.06% to 0.08% of Mg , 0.04%-0.1 rare earth element Re, 0.7-2.0% Ni, 0.7-1.0% Cu, 0.004-0.03% S, 0.016-0.15% P, and the rest consists of iron and impurities.

[0036] Its Brinell hardness is 170-230;

[0037] Its casting process includes smelting, casting, normalizing and tempering. In the smelting step, the iron raw material is smelted at high temperature to make it into a molten state. When the temperature of the molten metal reaches 1420-1440°C, ferrosilicon, ferromanganese, Copper; when the temperature of the molten metal reaches 1440-1450°C, it is taken out of the furnace, and the rare earth ferrosilicon-magnesium alloy is used for spheroidization treatment, and the triangular sample is poured to check the spheroidization effect. If the spheroidization is good, it can be poured; The sand casting process ...

Embodiment 3

[0045] A kind of high elongation ductile iron of the present invention, its chemical composition includes 3.0% C, 2.4% Si, 1.5% Mn, 0.06% Mg, 0.04% rare earth element Re, and 2.0% Ni, 0.9% Cu, 0.004% S, 0.14% P, and the rest are composed of iron and impurities;

[0046] Its Brinell hardness is 170-230;

[0047] The casting process includes smelting, casting, normalizing and tempering. In the smelting step, the iron raw material is smelted at high temperature to make it into a molten state. When the temperature of the molten metal reaches 1420°C, ferrosilicon, ferromanganese and copper are added; When the temperature of the molten metal reaches 1430°C, it is taken out of the furnace, treated with a rare earth ferrosilicon-magnesium alloy, poured a triangular sample, and checked the effect of the spheroidization, and it can be poured if the spheroidization is good; in the casting process, the sand casting process is used for casting 10 barrels of ductile iron expansion rings wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com