Reversing speed reducer

A speed reducer and positive rotation technology, which is applied in the direction of mechanical equipment, mining fluid, gear transmission, etc., can solve the problems of energy-saving effect reduction, inability to achieve precise balance, and decline in mechanical efficiency of beamless pumping units, and achieve improved Mechanical transmission efficiency, simple structure, and the effect of reducing the loss of mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

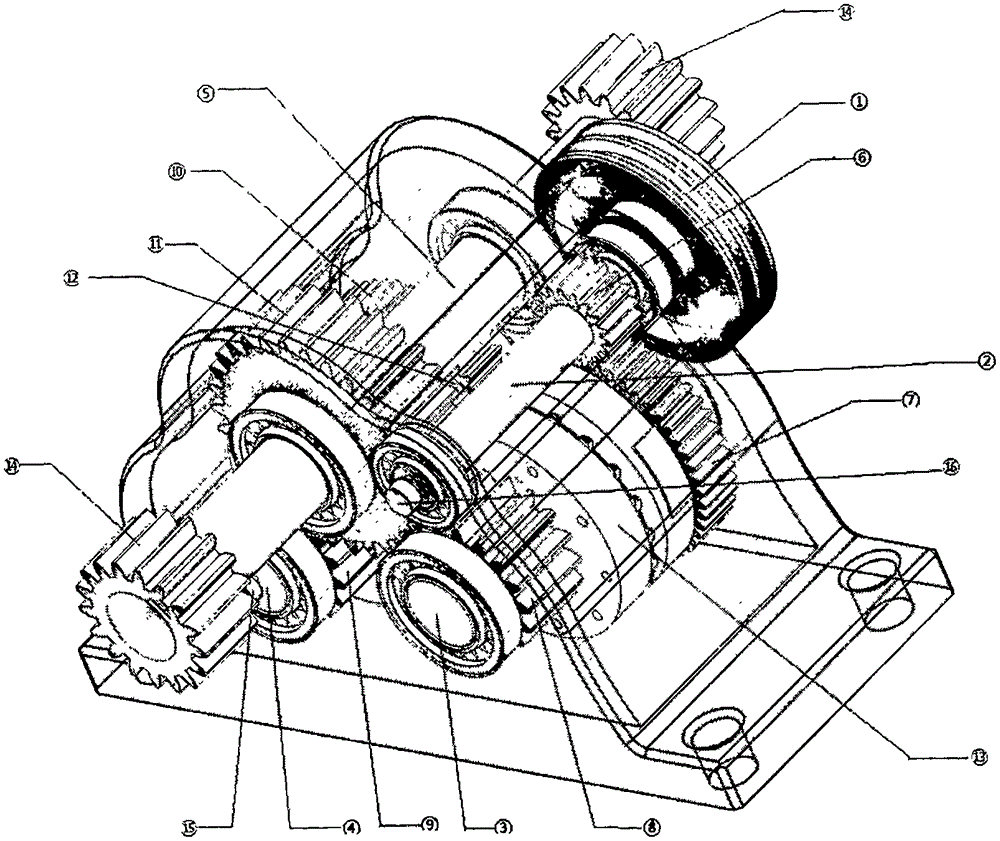

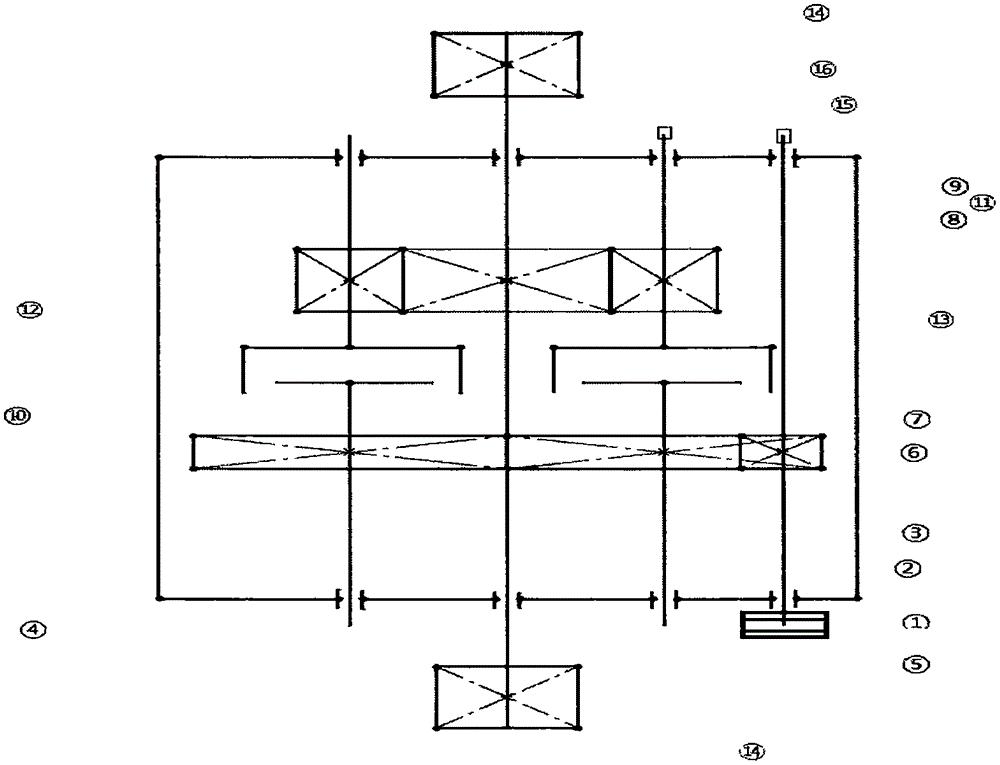

[0022] figure 1 There are four shafts in total, namely: power input shaft 2, intermediate shaft 3, intermediate shaft 4, and power output shaft 5. They are respectively fixed on the casing of the machine through bearings.

[0023] figure 1 Two groups of clutches (12, 13) are used in the middle, and every group of clutches is divided into two parts again, is combined or separated by mechanism driving.

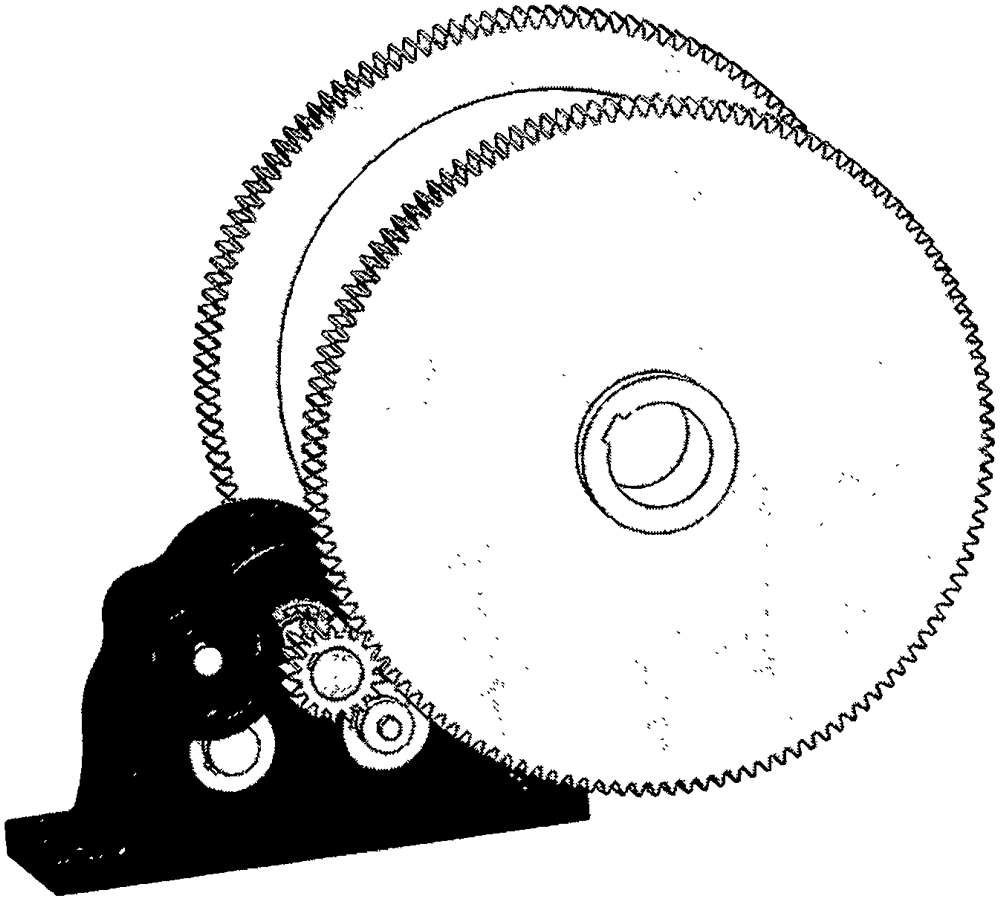

[0024] figure 1 One end of the pulley 1 is connected to the power source motor (omitted in the figure), the other end is fixed to the input shaft 2, the input shaft 2 is fixed to the driving gear 6, and the driving gear 6 is in phase with the input gear 7 of the intermediate shaft fixed on the intermediate shaft 3. meshing, the input gear 7 of the intermediate shaft 3 meshes with the input gear 10 of the intermediate shaft 4; when the power source motor rotates in a certain direction, the driving gear 6 drives the gear 7 to rotate, 7 drives the 10 to rotate, and the speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com