Manufacturing method for noctilucent heat dissipation cover of spot lamp

A manufacturing method and heat dissipation cover technology, which are applied to lampshades, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve problems such as poor practicability, and achieve improved practicability, simple process, and reasonable process arrangement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

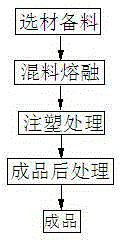

Method used

Image

Examples

Embodiment 1

[0015] The specific manufacturing steps of the luminous cooling cover of the spotlight mentioned in the present invention are as follows:

[0016] a) Material selection and preparation, the main components and percentage ratio of the cooling jacket are: luminous powder 5%, additive 2.3%, and the rest is resin; the average particle diameter of luminous powder is 350 mesh; the lubricant in the additive is selected Stearic acid amide, dispersant selects polyethylene wax, coupling agent selects amino silane coupling agent, antioxidant selects composite antioxidant of phosphite and hindered phenol, lubricant, dispersant, coupling agent and antioxidant The addition ratio of oxygen agent is about 5:4:3:2.5; the resin is PC;

[0017] b) The mixture is melted, and the luminous powder is pretreated with a coupling agent before mixing. The solvent is toluene, and the amount added is about 50% of the total luminous powder; add the luminous powder, solvent and coupling agent to the mixer ...

Embodiment 2

[0021] The specific manufacturing steps of the luminous cooling cover of the spotlight mentioned in the present invention are as follows:

[0022] a) Material selection and preparation, the main components and percentage ratio of the cooling jacket are: luminous powder 5.5%, additives 2.4%, and the rest is resin; the average particle diameter of luminous powder is 350 mesh; the lubricant in the additives is selected Stearic acid amide, dispersant selects polyethylene wax, coupling agent selects amino silane coupling agent, antioxidant selects composite antioxidant of phosphite and hindered phenol, lubricant, dispersant, coupling agent and antioxidant The addition ratio of oxygen agent is about 5:4:3:2.5; the resin is PMMA;

[0023] b) The mixture is melted, and the luminous powder is pretreated with a coupling agent before mixing. The solvent is toluene, and the amount added is about 50% of the total luminous powder; add the luminous powder, solvent and coupling agent to the m...

Embodiment 3

[0027] The specific manufacturing steps of the luminous cooling cover of the spotlight mentioned in the present invention are as follows:

[0028] a) Material selection and preparation, the main components and percentage ratio of the cooling jacket are: luminous powder 5.6%, additives 2.6%, and the rest is resin; the average particle diameter of luminous powder is 350 mesh; the lubricant in the additives is selected Stearic acid amide, dispersant selects polyethylene wax, coupling agent selects amino silane coupling agent, antioxidant selects composite antioxidant of phosphite and hindered phenol, lubricant, dispersant, coupling agent and antioxidant The addition ratio of oxygen agent is about 5:4:3:2.5; the resin is ABS;

[0029] b) The mixture is melted, and the luminous powder is pretreated with a coupling agent before mixing. The solvent is toluene, and the amount added is about 50% of the total luminous powder; add the luminous powder, solvent and coupling agent to the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com