Integrated cooker with efficient air suction function

A technology of integrated stoves and functions, which is applied in the field of integrated stoves, can solve the problems of affecting the kitchen environment, low smoke exhaust efficiency, clean cleaning, etc., and achieve the effects of reducing environmental pollution, high smoke exhaust efficiency, and reducing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

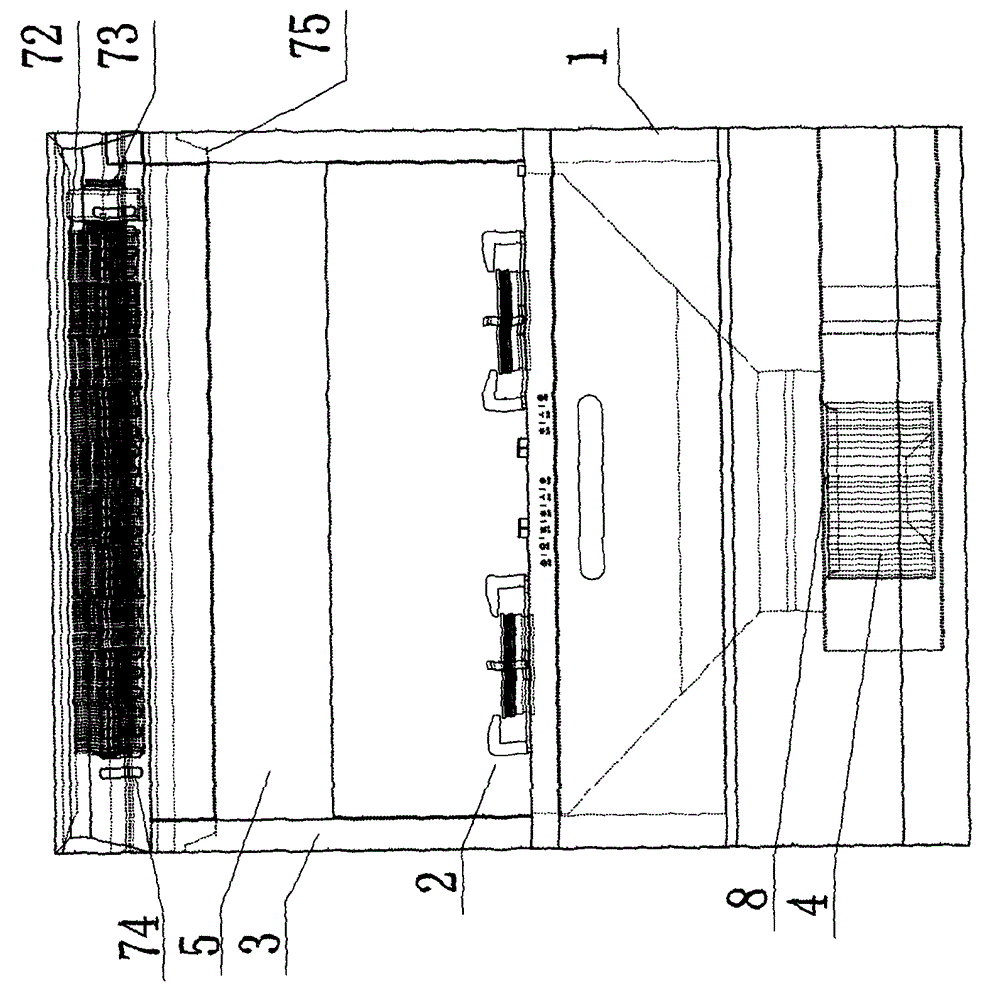

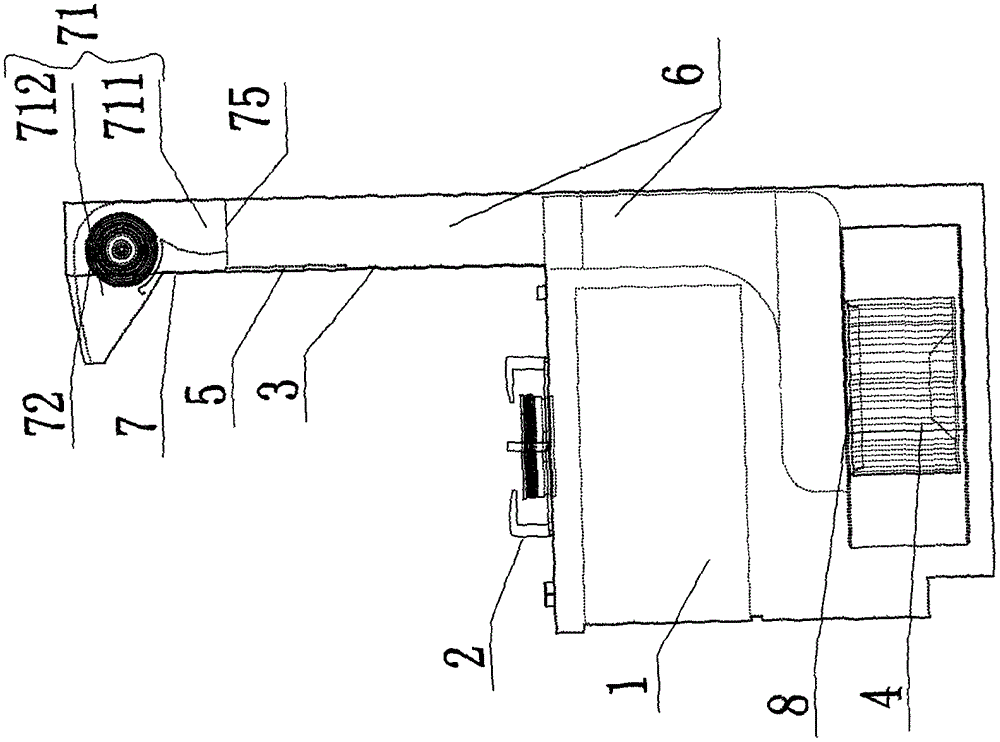

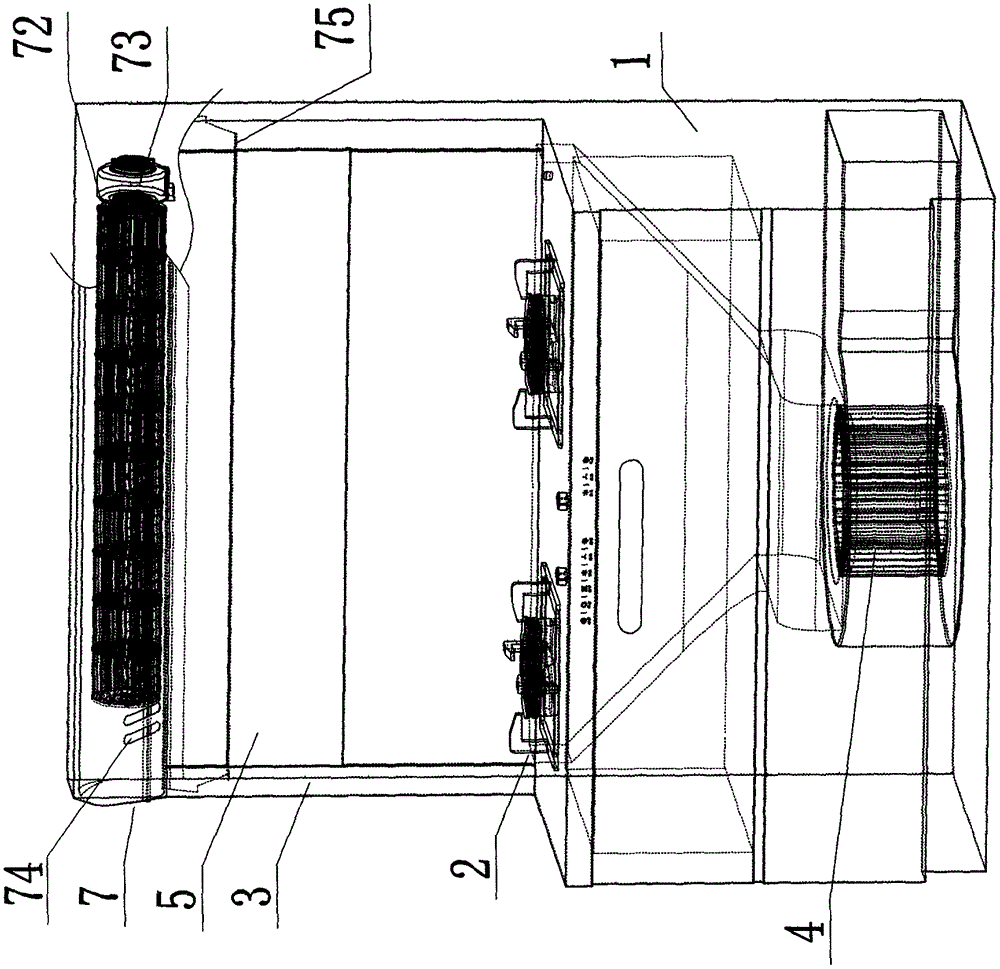

[0015] refer to figure 1 , figure 2 , image 3 As shown, an integrated cooker with a high-efficiency suction function includes a body 1, a cooker assembly 2, and a fume exhaust device. The centrifugal fan 4 in 1 has a smoke inlet 5 on the front of the smoke collecting hood 3, and the body 1 and the inside of the smoke collecting hood 3 are located between the smoke inlet 5 and the air inlet A8 of the centrifugal fan 4 as a negative pressure channel 6. A horizontal axial flow fan 7 is connected to the top of the smoke collecting hood 3, and the horizontal axial flow fan 7 includes a horizontal axial flow casing 71, a crossflow vane 72 placed in the horizontal axial flow casing 71, and a driving crossflow fan. The motor 73 of the blade 72, the horizontal axial flow casing 71 has an air inlet B74 and an air outlet 75, and the air outlet 75 communicates with the negative pressure passage 6, and the design of the horizontal axial flow fan 7 can further transfer oil, Smoke and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com