A drying system for poultry manure

A drying system and feces technology, applied in the direction of drying solid materials, promoting the preliminary treatment of solid materials drying, drying, etc., can solve the problems of lack of water filtration steps, low drying efficiency, easy to pollute the environment, etc., and achieve simple and labor-saving drying process , high drying efficiency, and the effect of preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

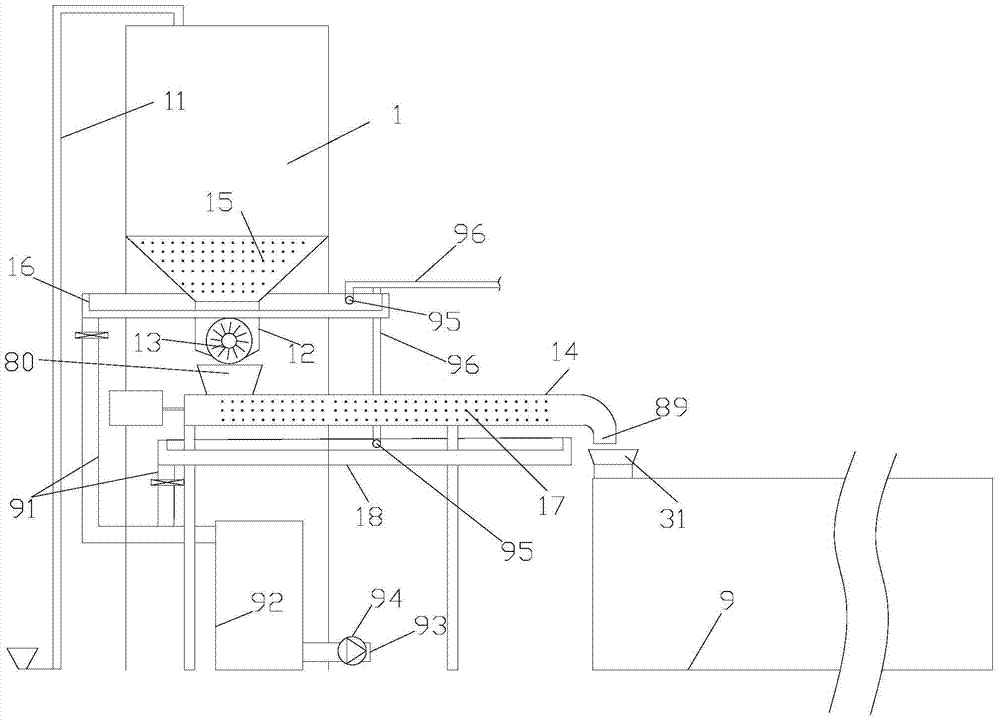

[0027] Such as figure 1 As shown, the poultry manure drying system described in this embodiment includes a feed bin 1 and a poultry manure dryer 9, and the poultry manure dryer 9 is provided with a feed hopper 31, wherein the poultry manure dryer 9 Adopt the "horizontal paddle type poultry manure dryer" as in Chinese patent application 2004200550802, the side of the feed bin 1 is provided with a feed hoist 11, and the feeding pipe 12 of the feed bin 1 is provided with a discharge valve 13 , the bottom surface of the feed bin 1 is covered with water leakage holes 15, the aperture of the water leakage holes 15 can be 2 mm to 5 mm, and the first water receiving tray 16 is provided on the feeding pipe 12; the feeding pipe The bottom of 12 is facing the inlet 80 of a screw conveyor 14, the shell 83 of the screw conveyor 14 is covered with leakage holes 17, and the second water receiving tray 18 is arranged under the screw conveyor 14; The outlet 89 of the conveyor 14 is connected ...

Embodiment 2

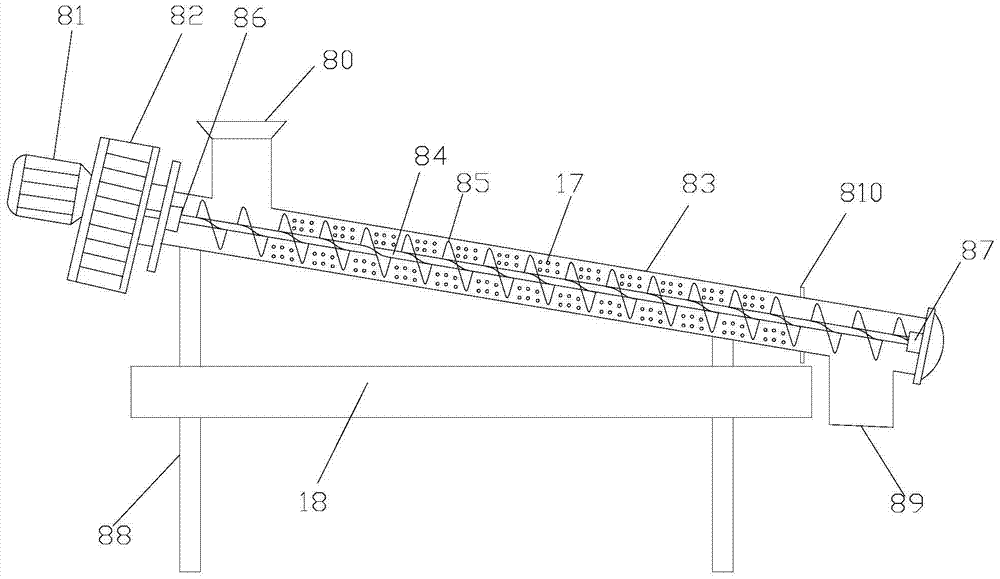

[0034] Such as figure 2 As shown, the drying system of poultry manure described in this embodiment is substantially the same as that of Embodiment 1, except that the screw conveyor 14 in Embodiment 1 is horizontal, while the screw conveyor 14 described in this embodiment 14 is made up of motor 81, speed reducer 82, casing 83, screw mandrel 84, screw blade 85, front bearing 86, tail bearing 87, bracket 88, and described bracket 88 is arranged at the bottom of casing 83, and described motor 81 and speed reducer 82 is located at the front of the casing 83, the front bearing 86 and the tail bearing 87 are respectively arranged at the front end and the tail end of the casing 83, and the two ends of the spiral mandrel 84 are respectively arranged in the front bearing 86 and the tail bearing 87, and the motor 81 The speed reducer 82 is connected with the spiral mandrel 84 through transmission; the shell 83 is in the inclined shape with a lower rear end, the front end of the shell 83...

Embodiment 3

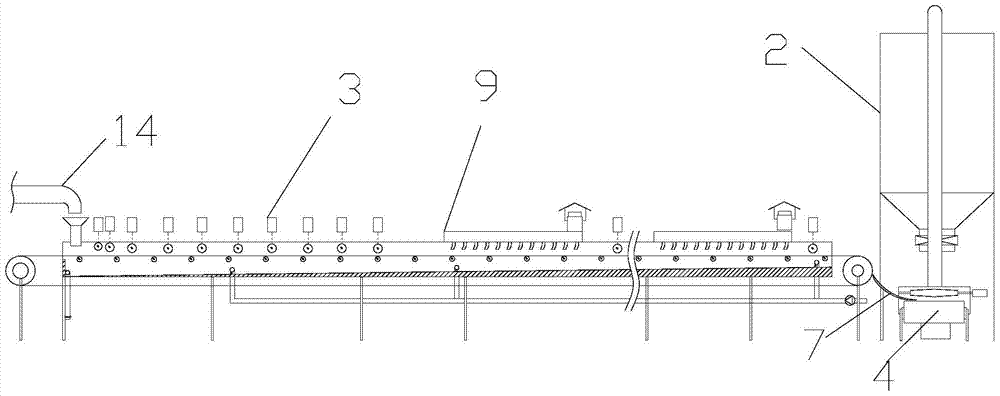

[0037] Such as image 3 , 5 As shown, the poultry manure drying system described in this embodiment is substantially the same as that of Embodiment 1, except that the poultry manure dryer 9 includes a first conveying device 3, a second conveying device 4 and a finished product bin 2. A finished product hoist 21 is provided on the side of the finished product warehouse 2;

[0038] Such as Figure 6 , 7 , 8, the main bodies of the first conveying device 3 and the second conveying device 4 are composed of a conveyor 5 and a cuboid hollow cover 6, and the conveyor belt 51 on the upper layer of the conveyor 5 passes through Inside the hollow cover 6, the conveyor belt 51 of the lower floor is located below the hollow cover 6, and a plurality of idler rollers 61 are set in the hollow cover 6 to support below the conveyor belt 51 of the upper layer; The upper position is respectively provided with a distribution roller 62 and a pressure roller 63, and the distribution roller 62 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com