Process-batch-model-based prediction method of oxygen flow rate for converter

A technology of process batch and prediction method, applied in the information field, can solve problems such as slow convergence speed, easy misjudgment, no batch model, etc., to achieve the effect of solving optimization problems, improving stability, and improving development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0108] The technical solution of the present invention will be further explained below in conjunction with the accompanying drawings, but the following content is not intended to limit the scope of protection of the present invention.

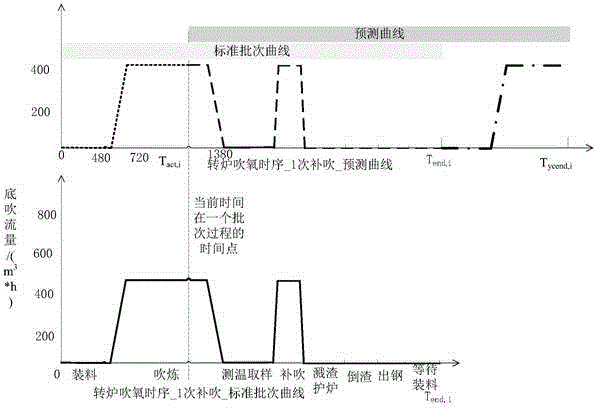

[0109] refer to figure 1 As shown, this method for predicting the oxygen flow rate of a converter based on the process batch model is realized according to the following steps:

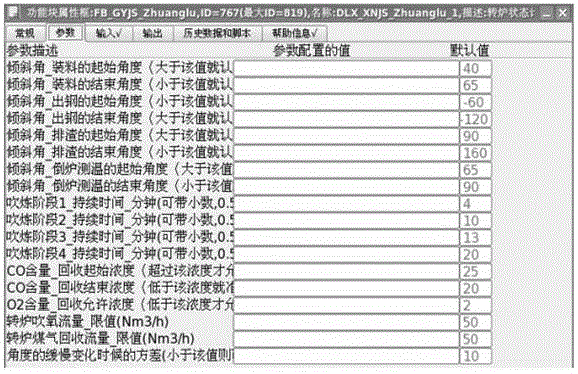

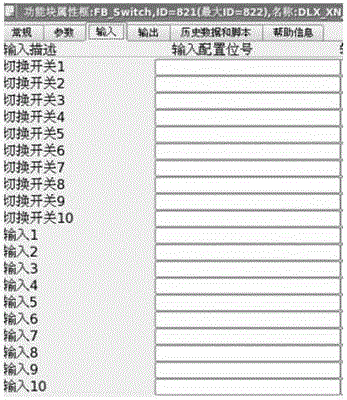

[0110] Step 1: In the graphical configuration calculation system, configure the parameters of the converter state calculation function block, the state switching time function block and the batch prediction function block.

[0111] It specifically includes the following sub-steps:

[0112] 1) Configure the parameters of the converter state calculation function block, such as the start value and end value of the inclination angle of the scrap loaded in the charging stage, etc. For details, the various numbers in step 2 are parameters, because each converter may be dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com