Metal hydride hydrogen storage and fuel cell combined system

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of many power-consuming equipment, different applicable designs, and large poisoning risks, so as to improve cooling performance, The effect of simplification of cooling channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

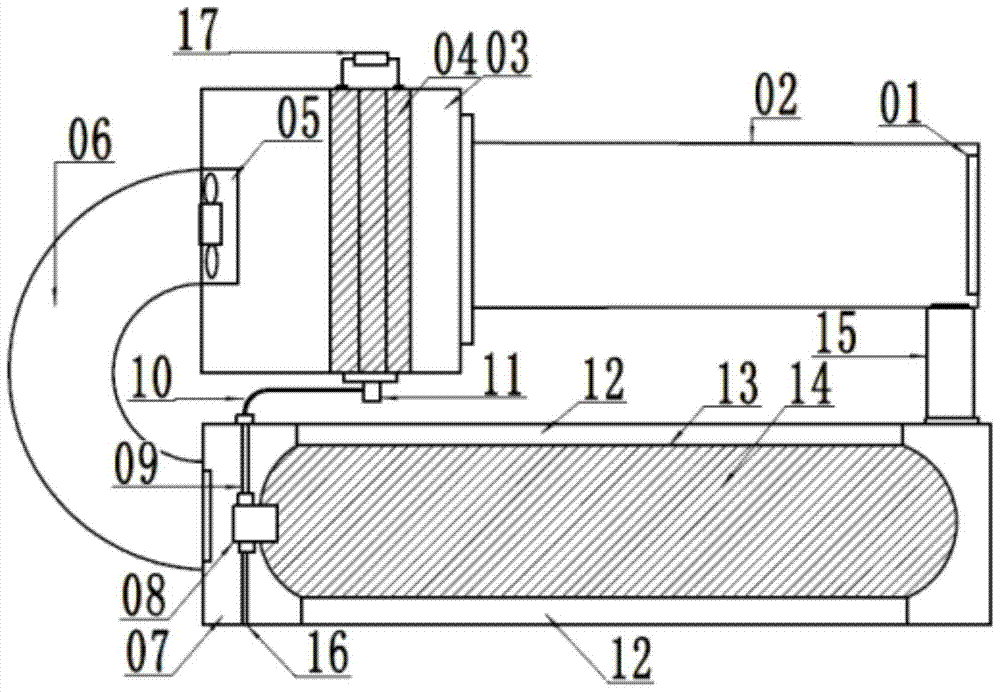

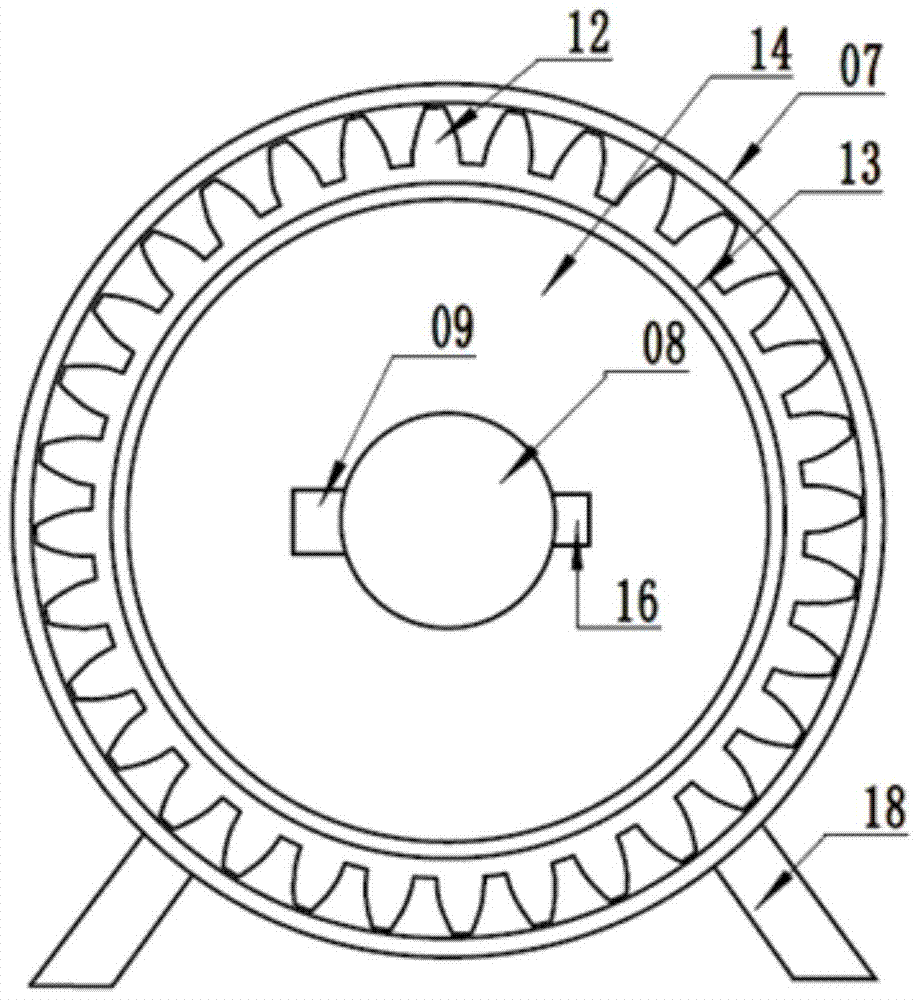

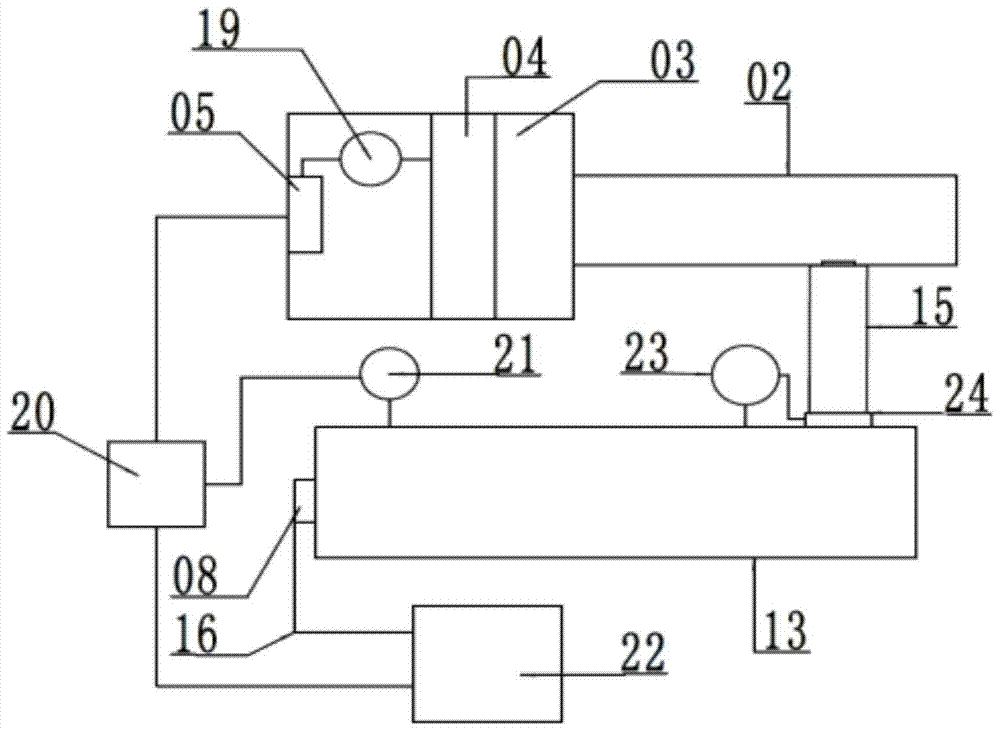

[0030] Figure 1-3 It is a metal hydride hydrogen storage and fuel cell combined system of the present invention. The system is an emergency fuel cell backup power system installed in a mobile phone base station, including a fuel cell system, a metal hydride hydrogen storage system and an electrolyzed water hydrogen production system.

[0031] The fuel cell system includes a fuel cell 3 which is a fuel cell stack 4 obtained by stacking a plurality of minimum structural units called single cells. The cathode side of the fuel cell 3 communicates with the air inlet pipe 2, and the air inlet of the air inlet pipe 2 is provided with a filter 1, which supplies the fuel cell 3 after the air is filtered, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com