A Control Method for Elongation Fluctuation of Temper Mill

A control method and elongation technology, applied in the direction of elongation control, etc., can solve the problems of stamping cracking, orange peel, the length of the out-of-tolerance section of the strip head and tail, and the fluctuation of elongation, etc., to improve the utilization rate of finished products, The effect of ensuring the elongation control accuracy and reducing the elongation control error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

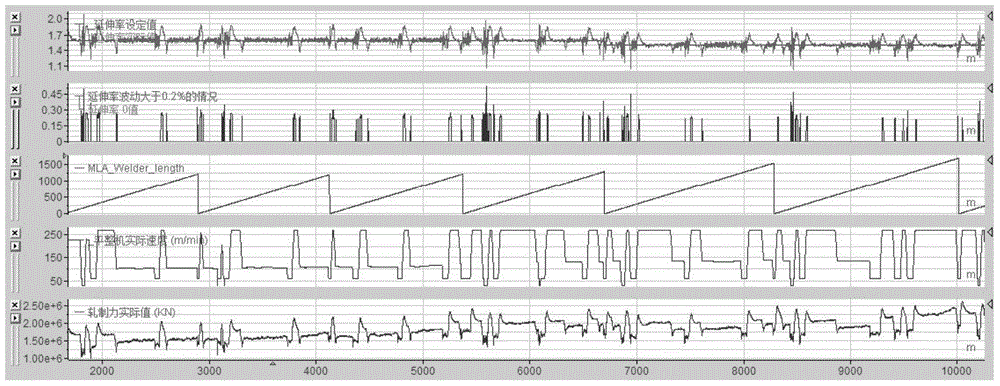

[0042] The invention provides a control method for the elongation fluctuation of the temper mill, which can improve the elongation control accuracy in the low speed and acceleration and deceleration stages, and at the same time ensure the elongation control accuracy in the high speed stage, and reduce the length of the out-of-tolerance section of the strip elongation at the head and tail .

[0043] The technical solution of the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

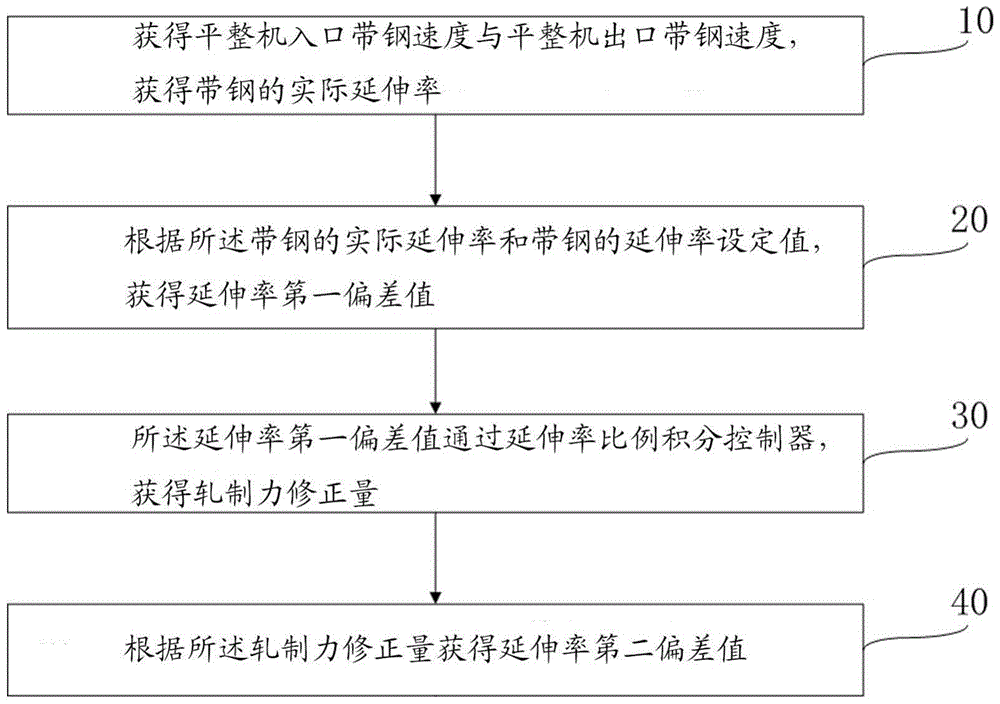

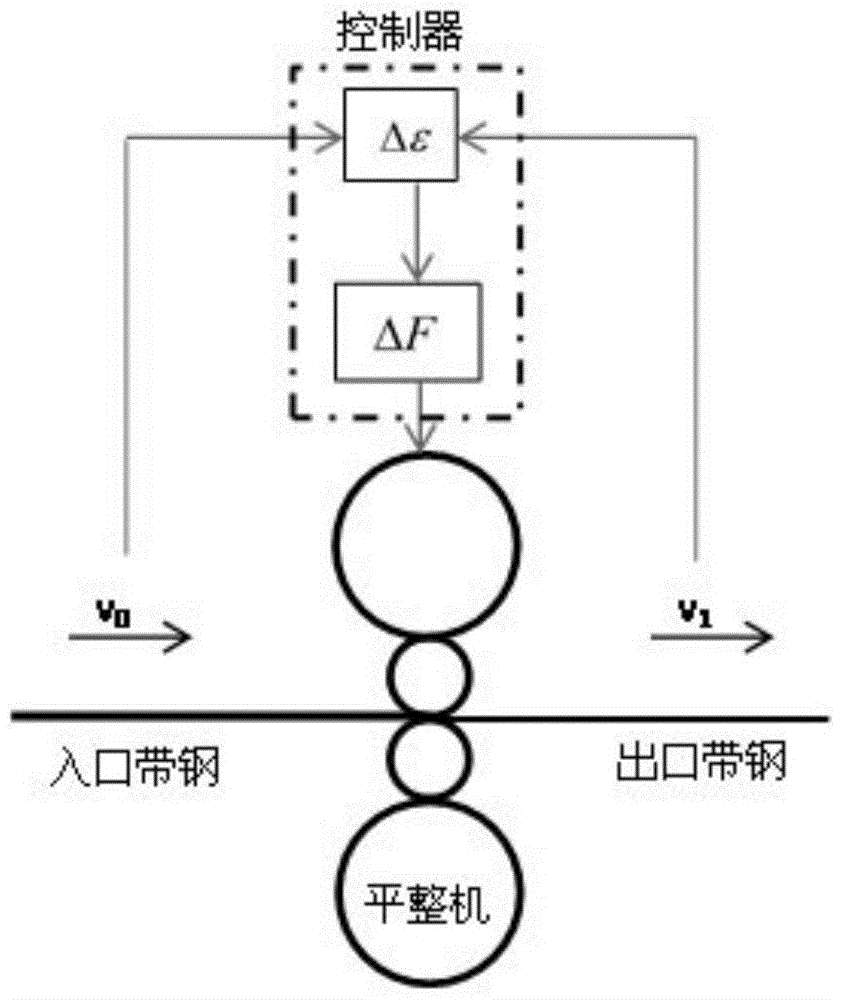

[0044] A method for controlling elongation fluctuations of a temper mill, which obtains the strip steel speed at the entrance of the temper mill and the strip steel exit speed of the temper mill, and obtains the actual elongation of the strip; according to the actual elongation of the strip and the The set value of elongation is used to obtain the first deviation value of elongation; the first deviation value of elongation is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com