Restoration method for mold fractures

A repair method and crack technology, which is applied in the field of mold crack repair, can solve problems such as brittle spalling of the weld surface, coarse grains of the weld structure, and high brittleness of the weld zone, etc., so that the degree of lattice distortion is weakened, and the weld surface Good molding and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

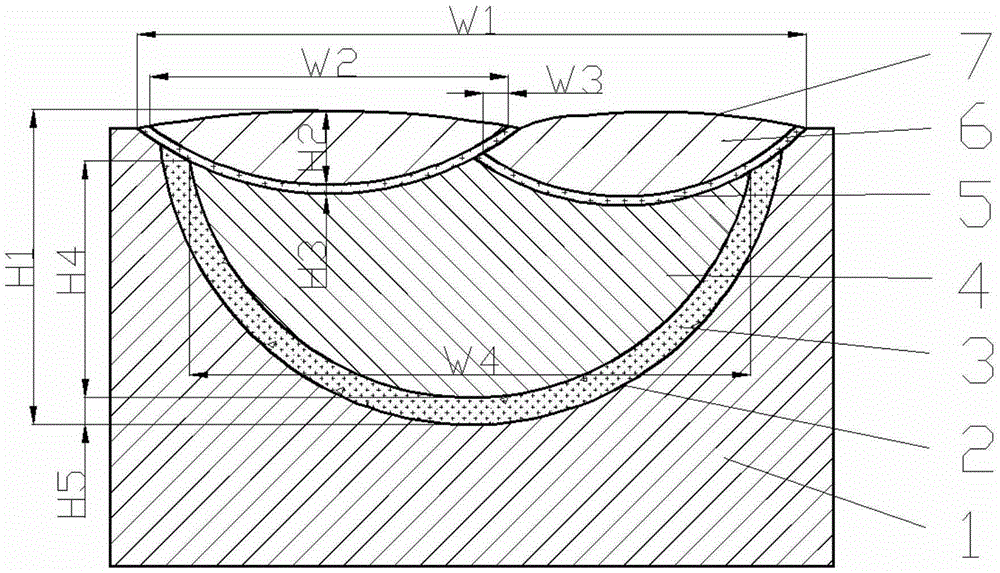

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as figure 1 , figure 2 Shown, the repair method of a kind of mold crack of the present invention,

[0034] According to the width and depth of the cracks, the cracks are divided into two categories: the width of the type a crack is between 0.5 and 3 mm, and the depth is between 1 and 5 mm; the width of the type b crack is more than 3 mm and the depth is more than 5 mm;

[0035] The repair of type a cracks includes the following steps:

[0036] (1) Remove the crack area on the surface of the mold with a manual grinding wheel;

[0037] (2), remove the thermal fatigue layer of the mold;

[0038] (3), carry out ultrasonic flaw detection to the crack area, if there are still cracks, then return to step (1); otherwise, perform step (4); thus ensure that the crack cleaning is completed;

[0039] (4) Clean the above-mentioned area wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com