Machining method for large-length-diameter-ratio deep through holes in end face of round plate

A technology with a large aspect ratio and a circular plate end face is applied in the field of machining, which can solve the problems of small diameter of the drill bit, low precision, and low positioning accuracy, and achieve the effect of improving the precision, improving the machining accuracy, and facilitating the clamping and positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

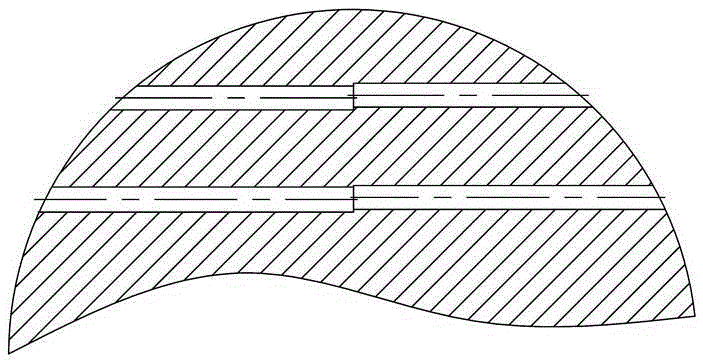

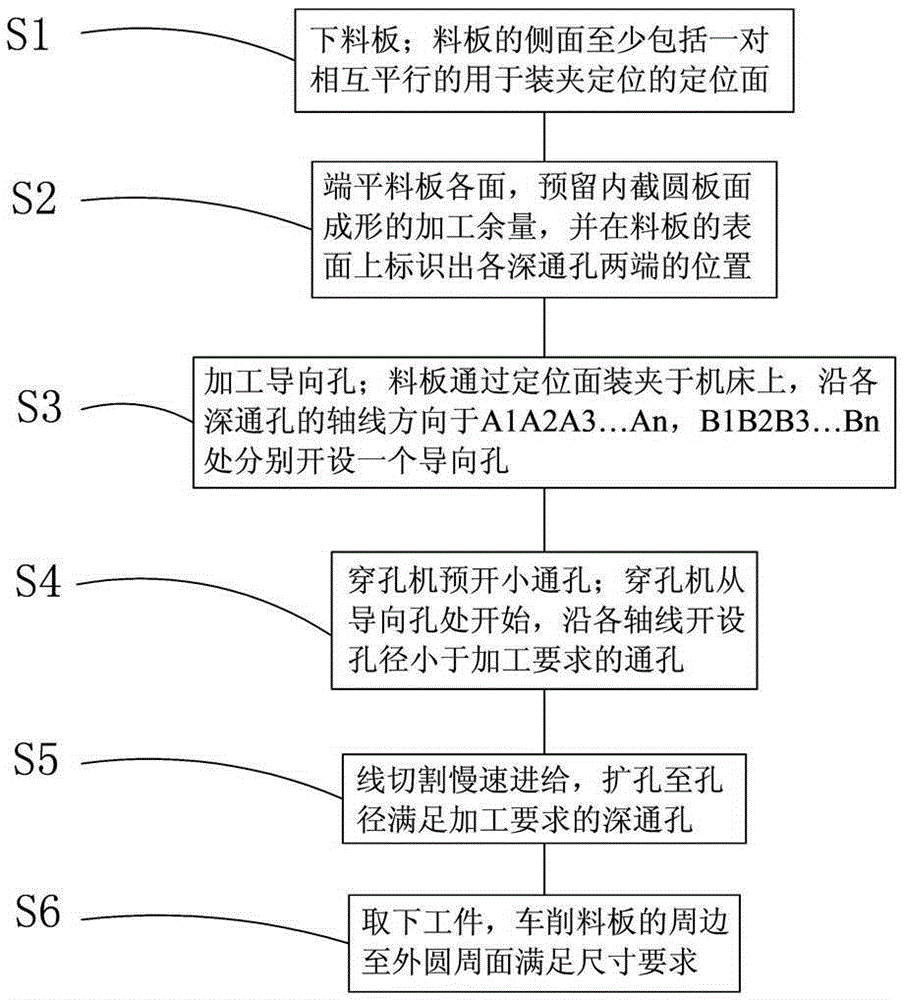

[0027] Figure 2 to Figure 5 An embodiment of the processing method of a deep through hole with a large aspect ratio on the end face of a circular plate of the present invention is shown, and the processing method includes the following steps:

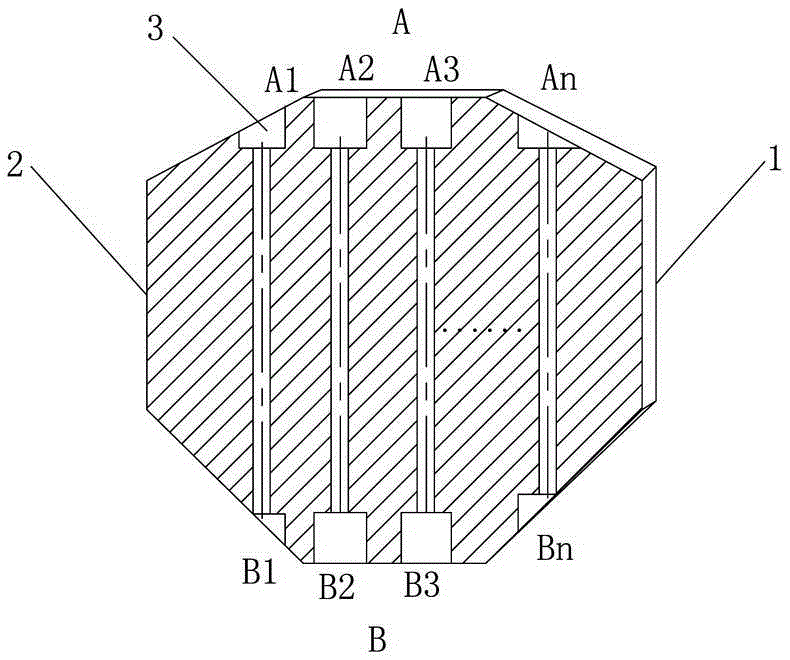

[0028] S1: blanking plate; the side of the material plate includes at least a pair of positioning surfaces (1, 2) parallel to each other for clamping and positioning;

[0029] S2: Flatten each surface of the material plate, reserve the processing allowance for forming the inner circular plate surface, and mark the positions of both ends of each deep through hole on the surface of the material plate; the positioning surface (1, 2) aligns the material plate The edge is divided into the upper section A and the lower section B. Mark A1A2A3...An along the edge of the upper section A, and B1B2B3...Bn along the edge of the lower section B. The connection line of A1B1 is the axis of the first deep through hole, and the connection line of AnBn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com