Comprehensive utilization and activation method of waste charcoal powder

An activation method and technology of charcoal powder, which are applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as ecological environment pollution, and achieve the effects of good adsorption performance, industrialization, and wide cost sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

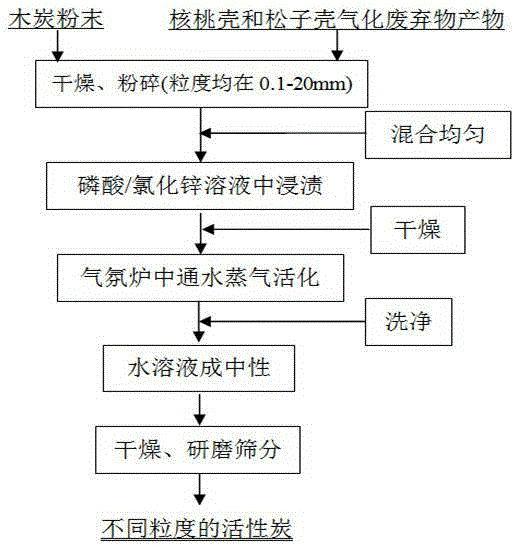

[0016] Such as figure 1 Shown, the comprehensive utilization and activation method of this waste charcoal powder, its concrete steps are as follows:

[0017] (1) Firstly, the solid carbon-containing products obtained by gasifying the waste charcoal powder, walnut shells and pine nut shells through the gasification furnace are dried at 80°C for 30 hours until the water content is below 5wt%, and then the gasification products are crushed to The particle size is 0.1mm, and the mixed material is obtained by mixing evenly according to the mass ratio of 60:20:20;

[0018] (2) Immerse the mixed material obtained in step (1) in phosphoric acid solution for 10 hours, and dry the impregnated raw material at 80°C for 20 hours until the water content is below 10wt%; the concentration of phosphoric acid in the phosphoric acid solution is 0.5mol / L , the solid-to-liquid ratio of the mixed material and the phosphoric acid solution is 0.03:1g / ml;

[0019] (3) Put the material treated in ste...

Embodiment 2

[0021] Such as figure 1 Shown, the comprehensive utilization and activation method of this waste charcoal powder, its concrete steps are as follows:

[0022] (1) Firstly, the solid carbon-containing products obtained by gasifying the waste charcoal powder, walnut shells and pine nut shells through the gasification furnace are dried at 120°C for 10 hours until the water content is below 5wt%, and then the gasification products are crushed to the particle size Average 20mm, according to the mass ratio of 30:50:20 mixed evenly to obtain the mixed material;

[0023] (2) Immerse the mixed material obtained in step (1) in zinc chloride solution for 30 hours, and dry the impregnated raw material at 120°C for 10 hours until the water content is below 10wt%; the concentration of phosphoric acid in the phosphoric acid solution is 2mol / L, the solid-to-liquid ratio of the mixed material and the zinc chloride solution is 1.00:1g / ml;

[0024] (3) The material treated in step (2) is activ...

Embodiment 3

[0026] Such as figure 1 Shown, the comprehensive utilization and activation method of this waste charcoal powder, its concrete steps are as follows:

[0027] (1) Firstly, the solid carbon-containing products obtained by gasifying the waste charcoal powder, walnut shells and pine nut shells through the gasification furnace are dried at 100°C for 20 hours until the water content is below 5wt%, and then the gasification products are crushed to the particle size Average 10mm, according to the mass ratio of 30:20:50 mixed evenly to obtain the mixed material;

[0028] (2) Immerse the mixed material obtained in step (1) in zinc chloride solution for 20 hours, and dry the impregnated raw material at 100°C for 15 hours until the water content is below 10wt%; the concentration of phosphoric acid in the phosphoric acid solution is 1mol / L, the solid-to-liquid ratio of mixed material and zinc chloride solution is 0.50:1g / ml;

[0029] (3) The material treated in step (2) is activated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com