Production method for buckwheat starch

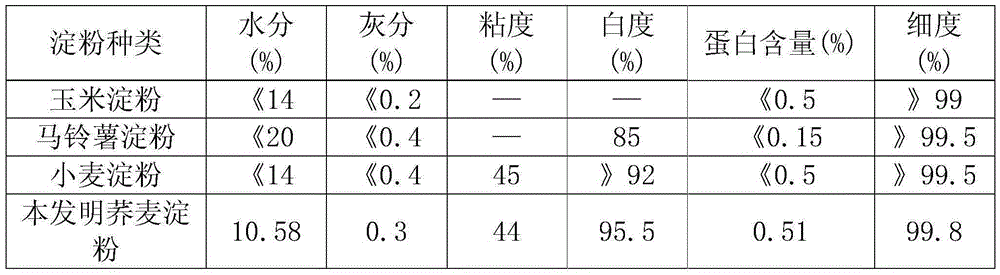

A production method, buckwheat technology, applied in the production field of buckwheat starch, can solve the problems of not being really extracted and fully utilized, and few research reports on buckwheat starch, so as to promote enthusiasm, reduce power consumption and production cost, and achieve great economy benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] A kind of production method of buckwheat starch, concrete steps are as follows:

[0019] 1. Soaking: Put the buckwheat rice in a sodium sulfite solution with a pH of 5-6. The soaking time is 18 hours in summer and 20 hours in winter. The soaking temperature is 40-45°C, and the soaking solution is adjusted with 1.0mol / L hydrochloric acid The pH value is 2-3; the weight ratio of soaking liquid to buckwheat is 2.5-4.5:1.

[0020] 2. Refining and sieving: remove the soaking liquid from the soaked buckwheat rice, wash it with clean water, grind it with distilled water at a ratio of 1:8-10 with a needle mill, and use a 0.088mm sieve for sampling Sieve, grind the filter residue repeatedly for 4-6 times, combine the pulp and milk, and pass through a 200-mesh sieve; separate the filter residue, and rinse it with clean water;

[0021] 3. Protein separation: Add 10% HCl solution to the combined fine milk after sieving to precipitate, centrifuge at a speed of 5000r / min for 10min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com