Reactively compatibilized butyl rubber/polyamide TPV (thermoplastic vulcanzate) and preparation method thereof

A thermoplastic vulcanizate, reactive compatibilization technology, applied in the field of polymer materials, can solve the problems of high requirements of industrial production and the inability to achieve compatibilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

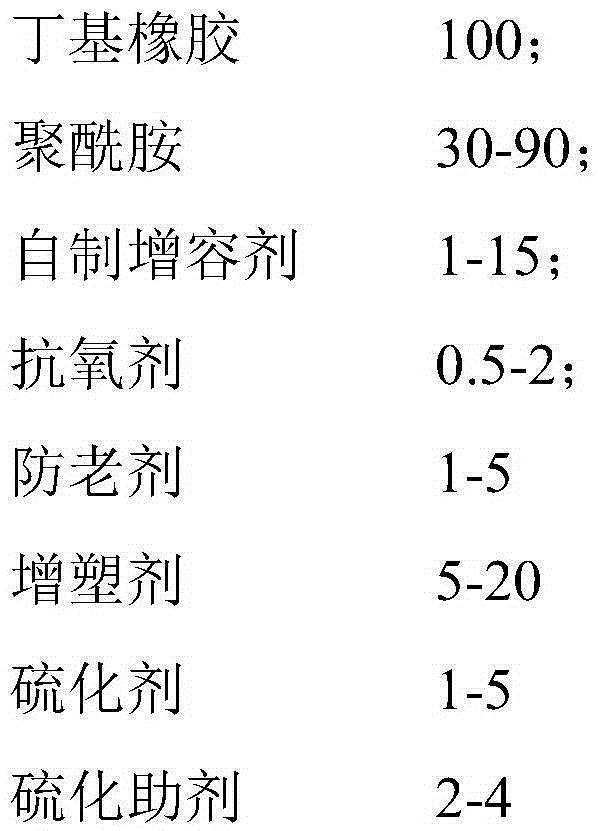

[0024] The basic composition and mass parts of the selected raw materials are as follows:

[0025]

[0026]

[0027] Wherein the basic composition and mass ratio of self-made compatibilizer are:

[0028] Halogen-free butyl rubber 100;

[0029] Glycidyl methacrylate 0.01;

[0030] Dicumyl peroxide 1

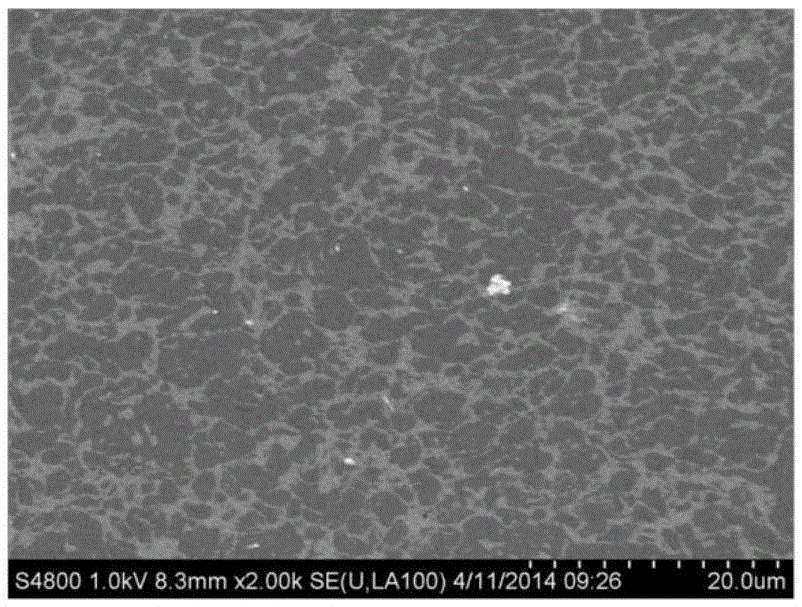

[0031] According to the above formula, first melt and mix halogen-free butyl rubber, glycidyl methacrylate, and dicumyl peroxide in a Haake internal mixer at 150°C for 5 minutes to obtain graft-modified halogen-free butyl rubber; then mix the dried polyamide 1010 with halogen-free butyl rubber at 190°C, add graft-modified halogen-free butyl rubber and antioxidants in proportion, wait until the mixture is uniform, and then discharge and cool to room temperature ; then mix with anti-aging agent, plasticizer, vulcanizing agent and vulcanization aid at room temperature to obtain a rubber-plastic premix; place the rubber-plastic premix in a screw extruder, set the vulcanizatio...

Embodiment 2

[0035] The basic composition and mass parts of the selected raw materials are as follows:

[0036]

[0037]

[0038] Wherein the basic composition and mass ratio of self-made compatibilizer are:

[0039] Chlorobutyl Rubber 100

[0040] 1,2-epoxybutene 0.5

[0041] Dicumyl peroxide 0.1

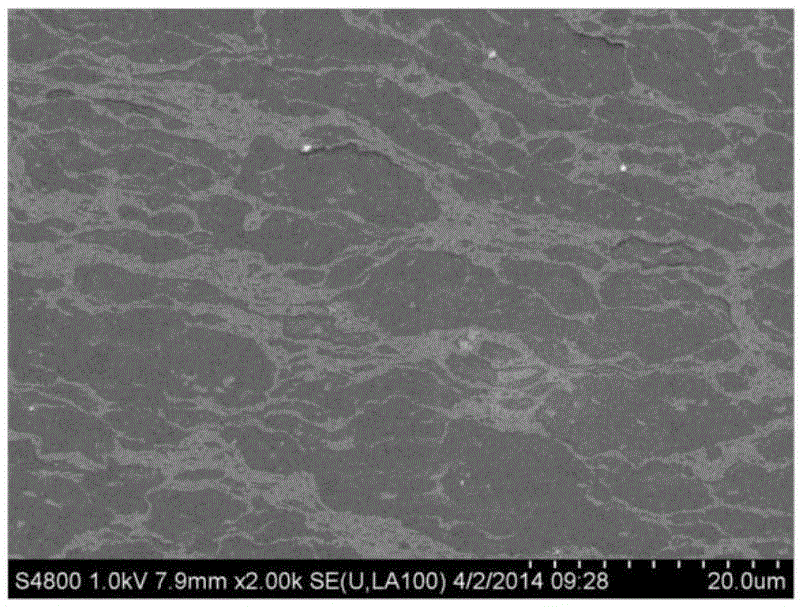

[0042] According to the above formula, chlorinated butyl rubber, 1,2-epoxybutene, and dicumyl peroxide were melted and mixed in a Haake internal mixer at 170°C for 8 minutes to obtain graft-modified butyl chloride. base rubber; then mix the dried polyamide 1212 and chlorinated butyl rubber at 200°C, add graft-modified chlorinated butyl rubber and antioxidants in proportion, wait until the mixture is uniform, and then discharge and cool to room temperature; then mix it with anti-aging agent, plasticizer, vulcanizing agent and vulcanization aid at room temperature to obtain a rubber-plastic premix; put the rubber-plastic premix in a screw extruder, set the vulcanization temperature to 20...

Embodiment 3

[0046] The basic composition and mass parts of the selected raw materials are as follows:

[0047]

[0048]

[0049] Wherein the basic composition and mass ratio of self-made compatibilizer are:

[0050] Bromobutyl Rubber 100

[0051] Acrylic anhydride 5

[0052] Dicumyl peroxide 3

[0053] According to the above formula, first melt and mix bromobutyl rubber, acrylic anhydride, and dicumyl peroxide in a Haake internal mixer at 190°C for 10 minutes to obtain graft-modified bromobutyl rubber; then bake Mix dry polyamide 12 and bromobutyl rubber at 210°C, add graft-modified bromobutyl rubber and antioxidants in proportion, wait for the mixture to be uniform, and then discharge and cool to room temperature; Mix with anti-aging agent, plasticizer, vulcanizing agent and vulcanization auxiliary agent to obtain rubber and plastic premix; put the rubber and plastic premix in the screw extruder, set the vulcanization temperature to 190°C, and the speed to 700rpm, and dynamicall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com