High pressure solvent delivery pump and minitype high pressure solvent delivery pump system

An infusion pump and high-pressure technology, applied in the field of liquid chromatography, can solve the problems of inability to achieve constant flow infusion, bulky structure, poor shock resistance, etc., and achieve the effects of light weight, wide flow range, and high motion positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In conjunction with the following specific embodiments and accompanying drawings, the invention will be further described in detail. The process, conditions, experimental methods, etc. for implementing the present invention, except for the content specifically mentioned below, are common knowledge and common knowledge in this field, and the present invention has no special limitation content.

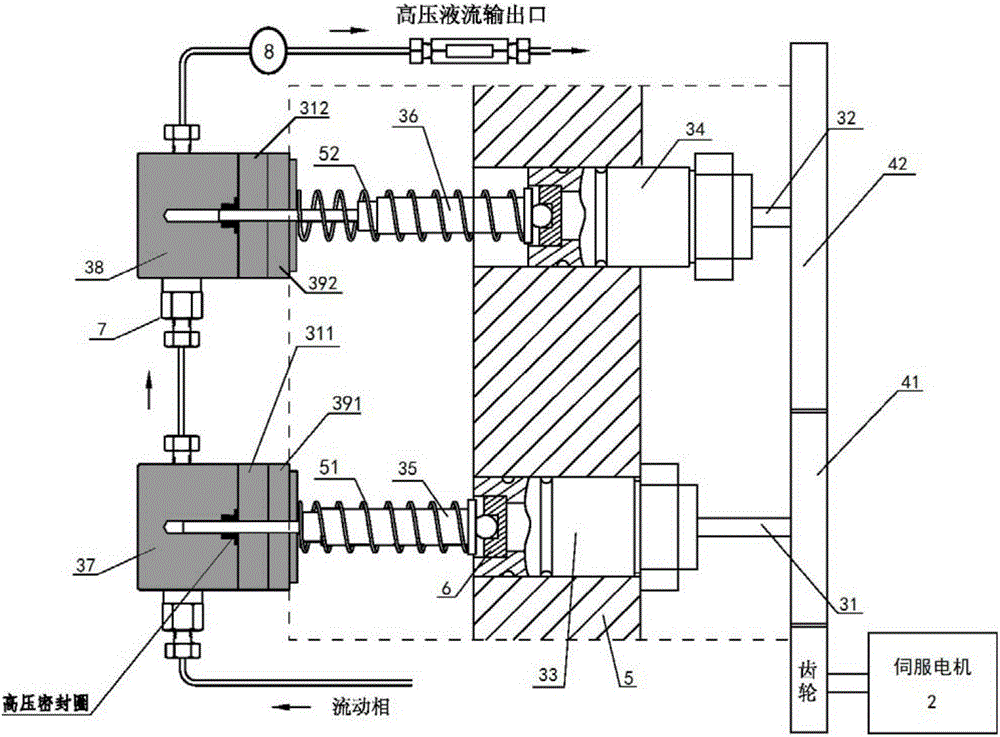

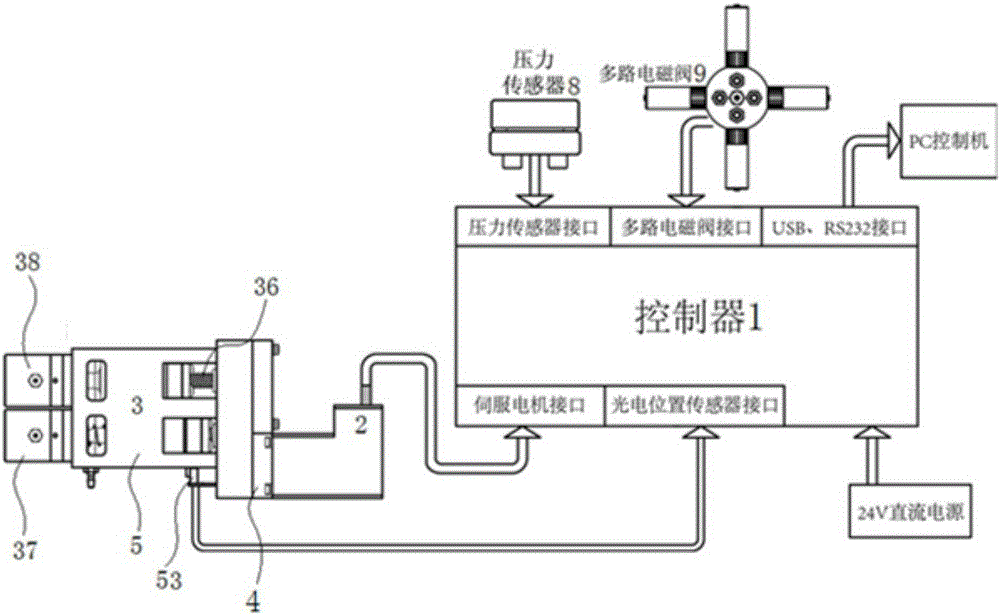

[0030] Such as figure 1 As shown, the present invention proposes a high-pressure infusion pump 3, comprising: a main pump ball screw 31, an auxiliary pump ball screw 32, a main piston 33, an auxiliary piston 34, a main plunger rod 35, an auxiliary plunger rod 36, Main pump head 37 and auxiliary pump head 38. The ball screw 31 of the main pump and the ball screw 32 of the auxiliary pump are linked through the gear 4, the nut of the ball screw 31 of the main pump is fixedly connected with the main piston 33, the nut of the ball screw 32 of the auxiliary pump is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com