A Porous Boiling Surface Preparation Method With Controlled Vaporization Core

A technology of vaporizing core and boiling surface, applied in the field of heat transfer enhancement, which can solve the problems of deteriorating heat transfer performance and prolonging the time of bubble detachment, so as to achieve the effects of promoting transportation, promoting technological innovation, and suppressing over-density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

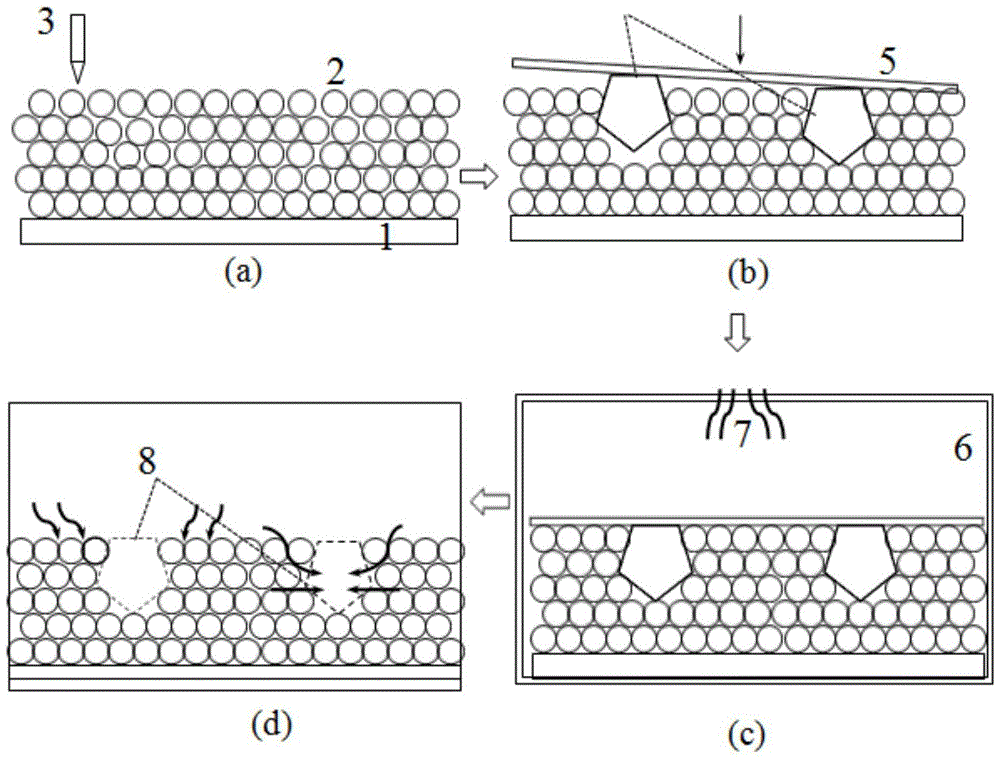

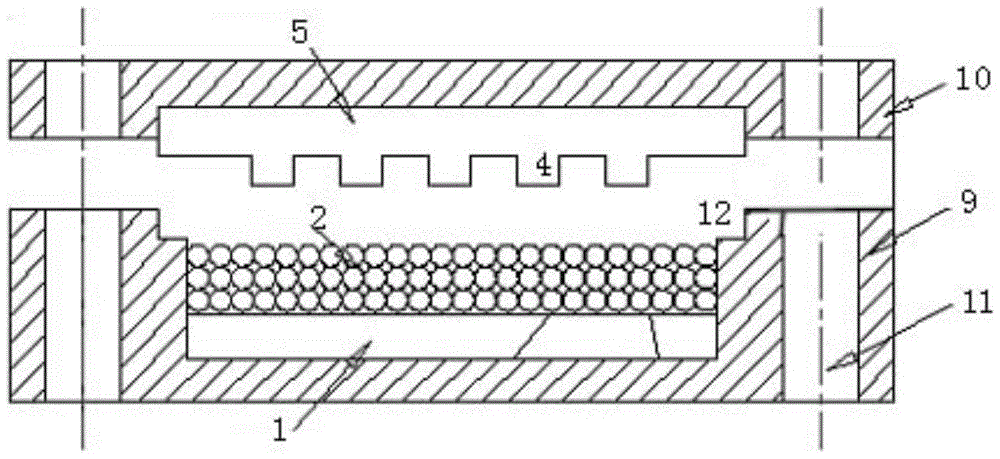

[0028] figure 1 It is a schematic flow chart of the preparation method of the fixed vaporization core porous boiling heat transfer surface. The preparation process is mainly divided into four operating steps: (a) accumulation of metal particles on the heat exchange surface (b) preparation of green embryos by pressing the metal particles on the surface of the template (c) blending and sintering under the protection of inert gas (d) demoulding to obtain vaporized The porous boiling surface of the core cavity.

[0029] In the step of accumulating metal particles on the heat exchange surface, first, the common heat exchange metal sample 1 needs to be cleaned and decontaminated, and the oxide layer is removed; then suitable metal micro-nano particles 2 are selected and screened to ensure that the particles are uniform Ensure that the sintered capillary gaps are not filled by tiny particles. The screened micro-nano particles 2 are deposited on the heat transfer base surface of the...

Embodiment 1

[0034] Sintering a metallic copper porous metal surface with a fixed vaporization core:

[0035] Choose copper metal as the heat exchange metal base material 30mm×40mm, firstly perform ultrasonic surface cleaning treatment; select metal Cu / CuO micron particles with a scale of 10 μm with good heat transfer performance; use a biological scraper to spread the metal particles on the substrate surface so that its thickness is around 100‐200 microns. Using the laser etching method, etched two rows of regular microcolumn structures with an equivalent diameter of 40μm on the photolithographic silicon surface of 30mm×40mm in size, and the height of the microcolumns is 25μm. The mold agent oxidizes polyethylene wax, put the template in the positioning cover, press it on the top of the metal particle layer, and assemble it in the positioning groove; sinter under nitrogen protection at 750°C for 3 hours, and then naturally cool under nitrogen protection; finally demould to obtain fixed va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com