Roll-to-roll preparation device and method for high-performance flexible transparent conductive film

A transparent conductive film, high-performance technology, applied to conductive layers, circuits, electrical components and other directions on insulating carriers, which can solve the problem of difficulty in forming conductive paths, inability to achieve cross-linking of linear conductive fillers, and affecting the electrical properties of flexible transparent conductive films. and other problems to achieve the effect of enhancing contact, improving stability and reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

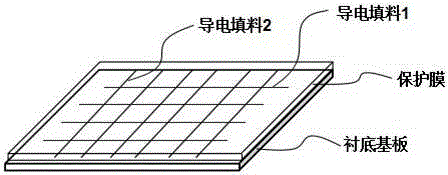

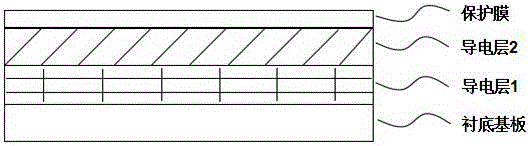

[0053] Embodiment 1 Roll-to-roll production of flexible transparent conductive film based on linear conductive filler

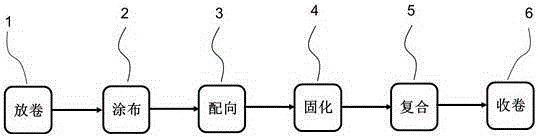

[0054] The nano-silver solution with a concentration of 10mg / ml and the HPMC aqueous solution with a concentration of 1wt% are mixed according to a mass ratio of 1:6 to obtain a conductive ink, wherein the average diameter of the nano-silver wire is 35nm and the length is 10um. Such as image 3 with Figure 4 As shown, the transparent and insulating plastic substrate roll material adopts PET (polyethylene terephthalate) roll film with high light transmittance and low haze, and the first PET roll film passes through the unwinding device 1. The roller 11 and the tension roller 12 are sent to the coating device 2, and the coating unit 21 is used to evenly coat one layer of ink comprising a linear conductive filler on the PET film, with a thickness of about 4-24um; The PET film of the ink is sent to the alignment device 3 (the alignment implementation methods u...

Embodiment 2

[0055] The roll-to-roll production of the flexible transparent conductive film of embodiment 2 multilayer conductive layer

[0056] The nano-silver solution with a concentration of 10mg / ml and the HPMC aqueous solution with a concentration of 1wt% are mixed according to a mass ratio of 1:6 to obtain a conductive ink, wherein the average diameter of the nano-silver wire is 35nm and the length is 10um. Such as image 3 with Figure 4 As shown, the transparent and insulating plastic substrate roll material adopts PET (polyethylene terephthalate) roll film with high light transmittance and low haze, and the first PET roll film passes through the unwinding device 1. The roller 11 and the tension roller 12 are sent to the coating device 2, and the coating unit 21 is used to uniformly coat one layer of ink comprising a linear conductive filler on the PET film, with a thickness of about 4-12um; The PET film of the ink is sent to the alignment device 3, and the linear conductive fill...

Embodiment 3

[0057] Embodiment 3 Meyer rod scrape coating alignment method

[0058] Such as Figure 5 As shown, the transparent and insulating plastic substrate roll material adopts a PET (polyethylene terephthalate) roll film with high light transmittance and low haze, and utilizes a coating unit 21 to evenly coat the PET film on the PET film. A layer of ink containing linear conductive fillers is spread, and at the alignment unit 31 , the linear conductive fillers are arranged in an orderly manner by using a Meyer rod (Meyerrod) doctor blade alignment method. Such as Figure 6 As shown, the linear conductive fillers on the PET film are initially randomly distributed, but after scraping with a Meyer rod, these linear conductive fillers show a tendency to align along the scraping direction. Therefore, the orientation of the linear conductive fillers on the PET film can be controlled by changing the direction of the Mayer rod coating. The thickness of the Meyer rod can be 4-24um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com