Drying apparatus

A kind of drying equipment and equipment technology, which is applied in the directions of tobacco drying, drying solid materials, drying gas arrangement, etc., and can solve the problem of huge drying equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

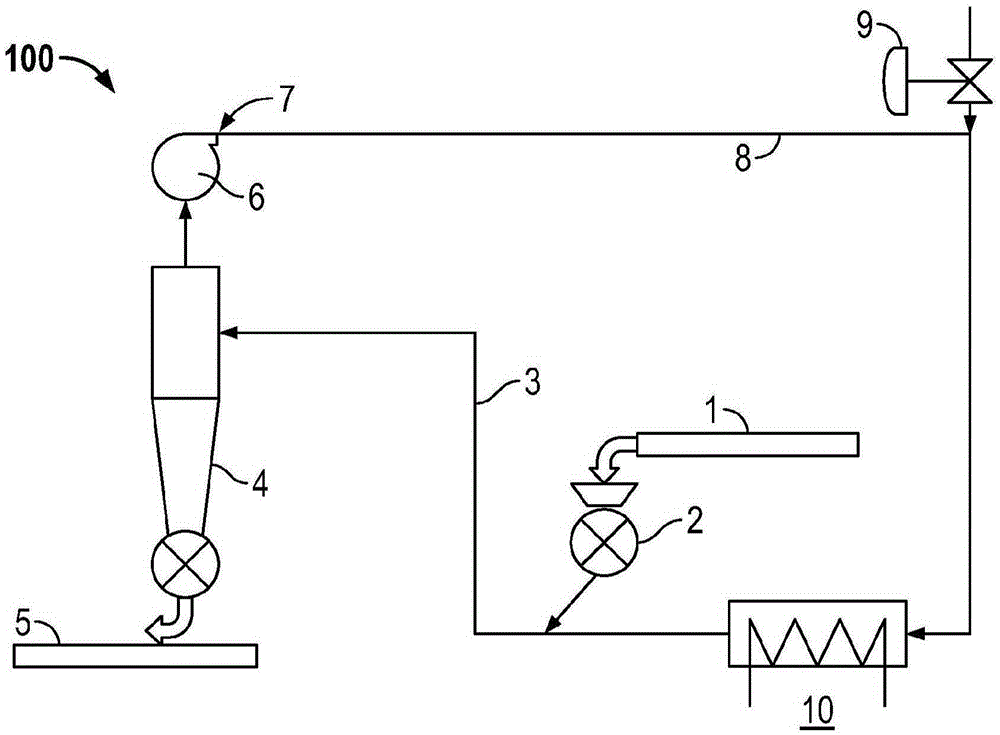

[0040] will now refer to Figure 1-9 The conventional known drying equipment and the drying equipment of the present invention are described. Some details of the structure and method of operation of known drying apparatuses have been described above and are summarized below. Moisture is removed from the moist tobacco product in the duct 3 which conveys and disperses the tobacco product in the air stream. The cyclone 4 acts to separate the tobacco product from the exhaust gas which is then treated and purified or recycled.

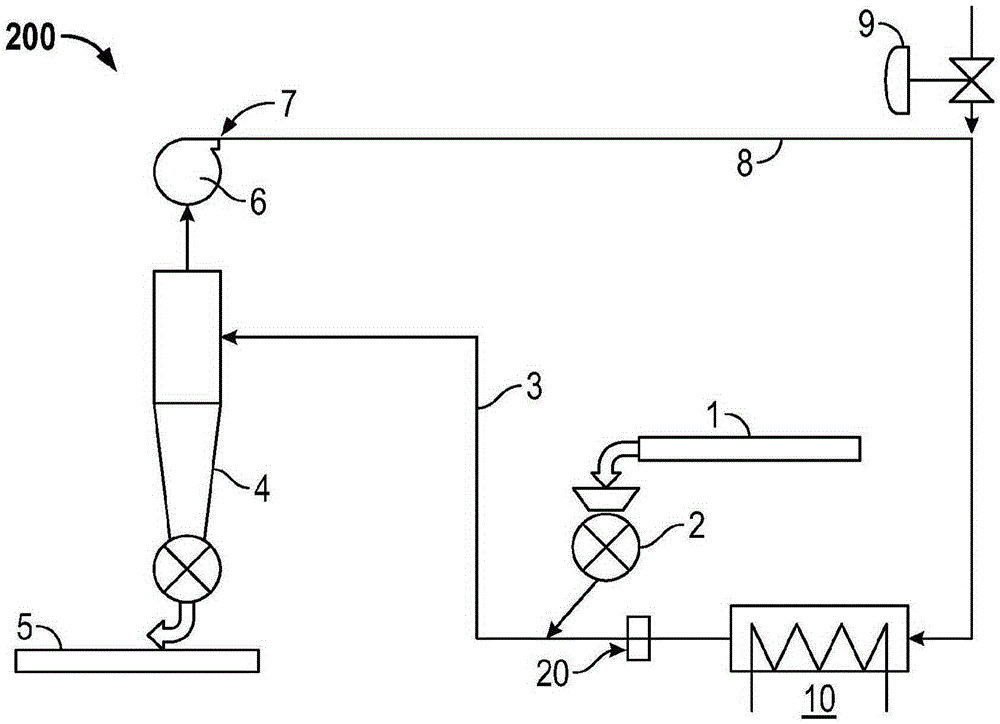

[0041] The drying apparatus 200, 300, 400, 500 of an embodiment of the present invention comprises substantially similar figure 1 Some parts of the parts of the apparatus shown in , therefore similar features are labeled with the same reference numerals. Refer to the attached figure 2 , which shows a drying device 200 according to a first embodiment of the present invention, the drying device 200 having a flow modification device 20 located in the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com