Special alkaline rice fertilizer capable of modifying soil persistently and production process thereof

An alkaline fertilizer and production process technology, applied in the direction of fertilizer mixture, application, fertilization device, etc., can solve the problems of inability to continuously improve paddy fields, nutrient utilization rate needs to be improved, and low organic matter content, etc., to achieve direct regulation of soil acidity , Promote the formation of soil aggregate structure and protect root hairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

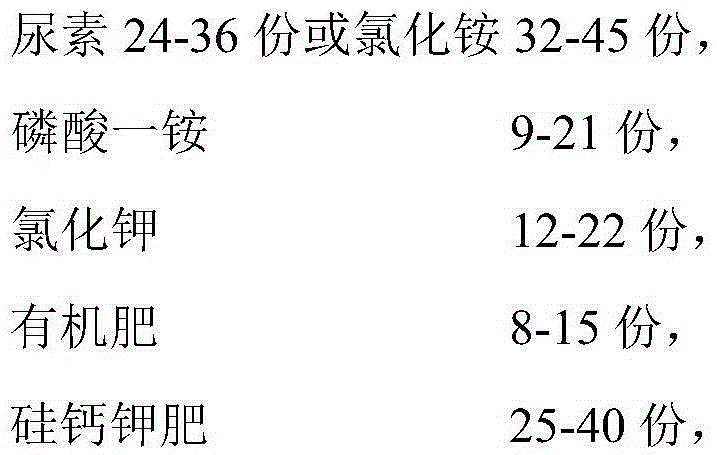

[0057] Embodiment 1 makes 30% (15-6-9) the special-purpose alkaline fertilizer for paddy rice of persistent effect improving soil. Take each component by the following parts by weight:

[0058]

[0059] The above-mentioned solid components crushed to 80-100 mesh are sent to the mixer to stir and mix evenly, and the steam is passed into the granulator for granulation: the granulated material is sent to the dryer for drying, and then sieved, Unqualified large-grained materials are crushed and returned to the granulator for re-granulation with fine powder; qualified materials are transported to the second-stage granulator for spraying with a 3% polyglutamic acid solution, and under the action of fertilizer granules preheating, The polyglutamic acid forms a film on the surface of the fertilizer granules, and after cooling, metering and packaging, the finished product of alkaline fertilizer for rice with 30% (15-6-9) sustained effect for soil improvement is obtained. That is, t...

Embodiment 2

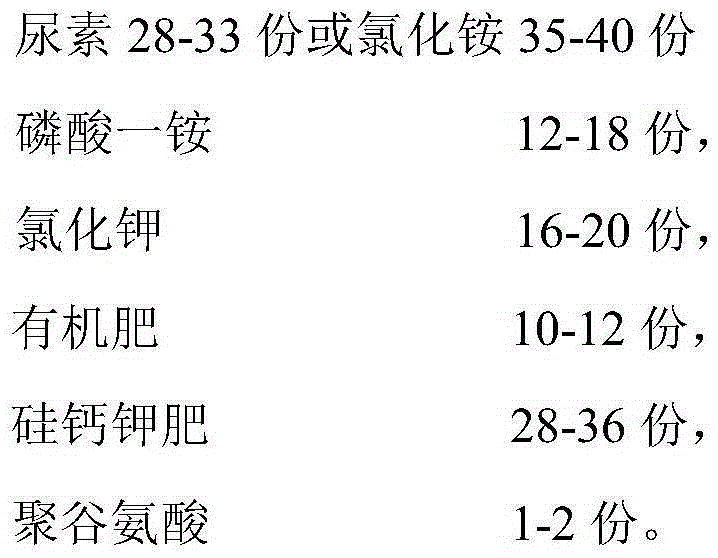

[0060] Embodiment 2 Make 34% (18-8-8) special alkaline fertilizer for rice with persistent effect improving soil. Take each component by the following parts by weight:

[0061]

[0062]

[0063] The above-mentioned solid components crushed to 80-100 mesh are sent to the mixer to stir and mix evenly, and the steam is passed into the granulator for granulation: the granulated material is sent to the dryer for drying, and then sieved, Unqualified large-grained materials are crushed and returned to the granulator for re-granulation with fine powder; qualified materials are transported to the second-stage granulator for spraying with a 4% polyglutamic acid solution. Glutamic acid forms a film on the surface of the fertilizer granules, and after cooling, metering and packaging, the finished product of alkaline fertilizer for rice with 34% (18-8-8) sustained effect for soil improvement is obtained. That is, the total nutrient content is 34%, and the nitrogen, phosphorus, and p...

Embodiment 3

[0064] Embodiment 3 makes 33% (15-6-12) the special alkaline fertilizer for paddy rice of persistent effect improving soil. Take each component by the following parts by weight:

[0065]

[0066] The above-mentioned solid components crushed to 80-100 mesh are sent to the mixer to stir and mix evenly, and the steam is passed into the granulator for granulation: the granulated material is sent to the dryer for drying, and then sieved, Unqualified large-grained materials are crushed and returned to the granulator for re-granulation with fine powder; qualified materials are transported to the second-stage granulator for spraying with 2% polyglutamic acid solution, and under the action of preheating the fertilizer granules, polyglutamic acid The acid forms a film on the surface of the fertilizer granules, and after cooling, metering and packaging, the finished product of the special alkaline fertilizer for rice with a sustained effect of 33% (15-6-12) for soil improvement is obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com