Method for raising utilization rate of silicon core master batch

A utilization rate and masterbatch technology, applied in the field of improving the utilization rate of silicon core masterbatch, can solve problems such as waste of silicon core masterbatch, and achieve the effects of improving utilization rate, easy removal and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

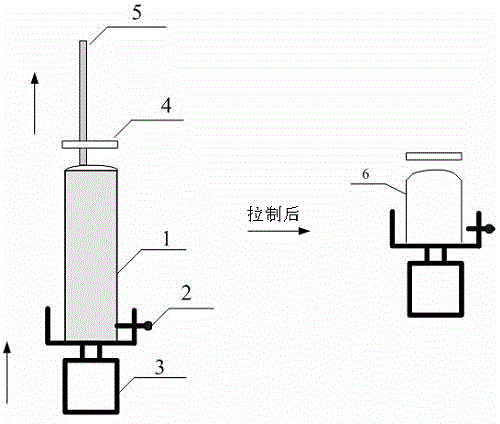

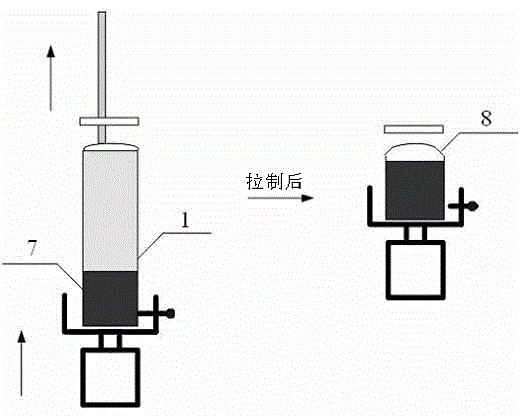

[0028] A method to improve the utilization rate of the silicon core masterbatch. One end of the cut silicon core masterbatch is connected to one end of the bar, and the other end of the bar is clamped in the material seat of the silicon core furnace, and then the silicon core master The material is drawn.

Embodiment 2

[0030] A method to improve the utilization rate of the silicon core masterbatch. One end of the cut silicon core masterbatch is connected to one end of the bar, and the other end of the bar is clamped in the material seat of the silicon core furnace, and then the silicon core master The material is drawn.

[0031] After the drawing is completed, the bar with the tail is removed, the tail is removed, and the bar is used continuously.

Embodiment 3

[0033] A method for improving the utilization rate of the silicon core masterbatch. One end of the cut silicon core masterbatch is connected to one end of the bar, and the other end of the bar is clamped in the material seat of the silicon core furnace, and then the silicon core master The material is drawn.

[0034] After the drawing is completed, the bar with the tail is removed, the tail is removed, and the bar is used continuously.

[0035] The silicon core masterbatch and the bar are bonded by a high-temperature adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com