Camera module set

A camera module and image sensor technology, applied in radiation control devices and other directions, can solve the problems of difficult manufacturing reliability, high clean room level, and long cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

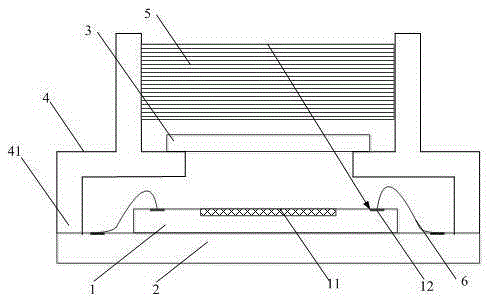

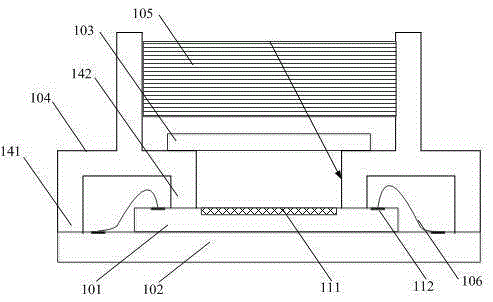

[0026] figure 2 It is a schematic structural diagram of a camera module according to Embodiment 1 of the present invention. The camera module includes an image sensor chip 101, a mounting frame 104, and a circuit substrate 102, and an inner layer support structure 142 is added on the peripheral bonding structure 141 between the installation frame 104 and the circuit substrate 102, and the inner layer support structure 142 Contacting the periphery of the photosensitive area 111 of the image sensor chip 101 makes the camera module more robust.

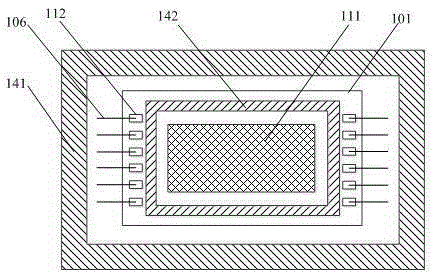

[0027] Wherein, the inner support structure 142 and the image sensor chip 101 can form a closed structure or an open structure. image 3 It is a top view of the closed structure of the camera module according to Embodiment 1 of the present invention; Figure 4 , Figure 5 It is a top view of the open structure of the camera module according to Embodiment 1 of the present invention.

[0028] Such as image 3 As shown, usually the im...

Embodiment 2

[0032] Figure 6 It is a schematic structural diagram of a camera module according to Embodiment 2 of the present invention. The camera module includes an image sensor chip 201, a mounting frame 204, and a circuit substrate 202, and an inner support structure 242 is added on the peripheral bonding structure 241 of the mounting frame 204 and the circuit substrate 202, and the inner support structure 242 Contacting the periphery of the photosensitive area 211 of the image sensor chip 201 makes the camera module more robust.

[0033] Different from Embodiment 1, the inner support structure 242 in this embodiment cannot be arranged between the photosensitive region 211 and the pad 212, but can only be arranged in the non-pad area around the photosensitive region 211, such as Figure 7 As shown in the horizontal extension of the inner support structure 242, the inner support structure 242 and the photosensitive surface of the image sensor chip 201 form a stepped inner cavity, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com