A kind of insulating oil automatic filtering system and filtering method thereof

An automatic filtering and insulating oil technology, applied in the direction of filtration separation, separation method, filtration circuit, etc., can solve the problems of secondary pollution of insulating oil, high process requirements, cracking and aging, etc., so as to avoid secondary pollution and achieve good oil filtering effect , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

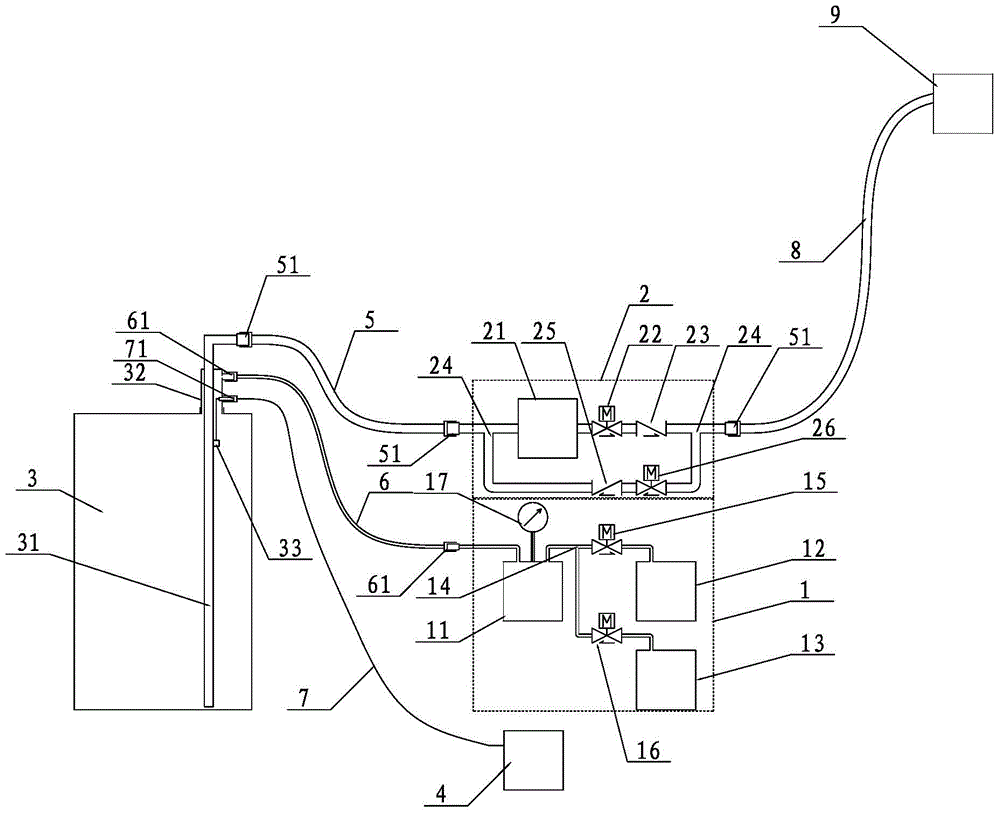

[0021] Such as figure 1 As shown, an insulating oil automatic filtering system includes an air circuit unit 1, an oil circuit unit 2, an oil barrel 3 and a control unit 4, wherein the oil barrel 3 is provided with an oil circuit hard pipe 31, and the oil circuit hard pipe The upper port of 31 exposes the top of the oil barrel 3, and is connected with the first oil hose 5 through the quick oil joint 51, and the lower port of the oil hard pipe 31 is located at the bottom of the oil barrel 3, but does not touch the bottom of the oil barrel; the oil barrel 3 There is also an oil barrel interface adapter 32 on the top, the oil barrel interface adapter 32 is connected to the air hose 6 through the quick air joint 61, and connected to the signal line through the aviation plug 71, and the oil barrel 3 is provided with a liquid level The sensor 33, the liquid level sensor 33 is connected with the aviation plug 71, and is used for monitoring the height of the oil level in the barrel. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com