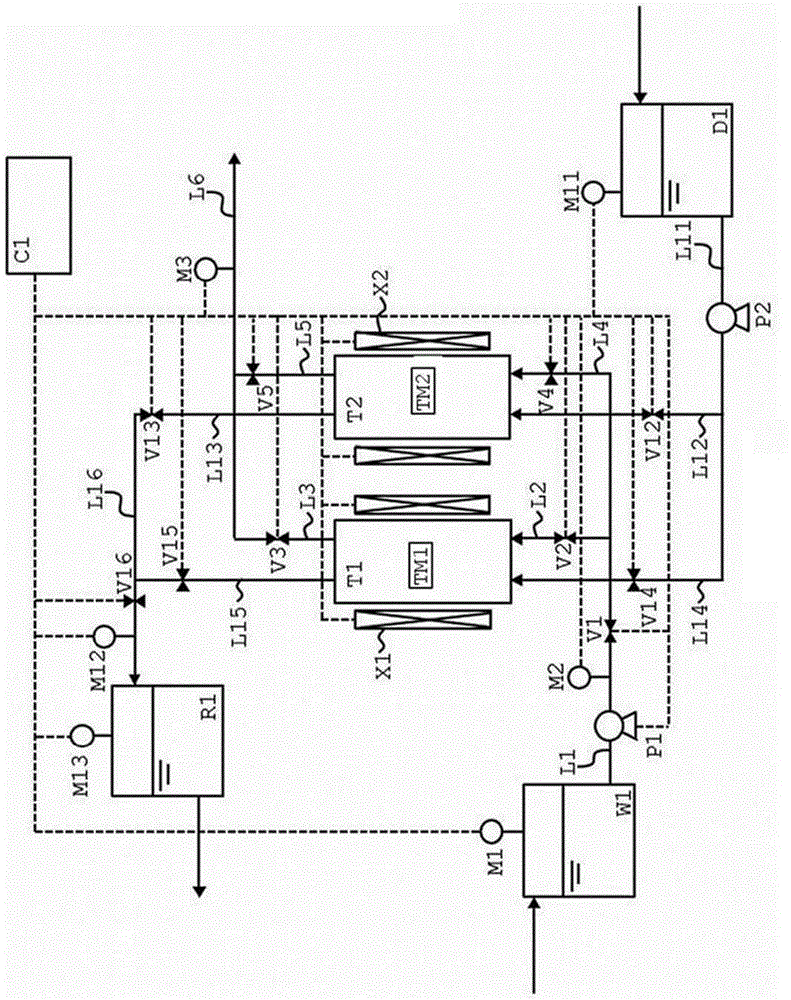

Iodine adsorbent, water treatment tank and iodine adsorbing system

An iodine adsorption and functional group technology, which is applied in the fields of adsorption water/sewage treatment, water/sewage treatment, water treatment parameter control, etc. It can solve problems such as dissolving into rainwater or river water, increasing silver loading, and silver dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

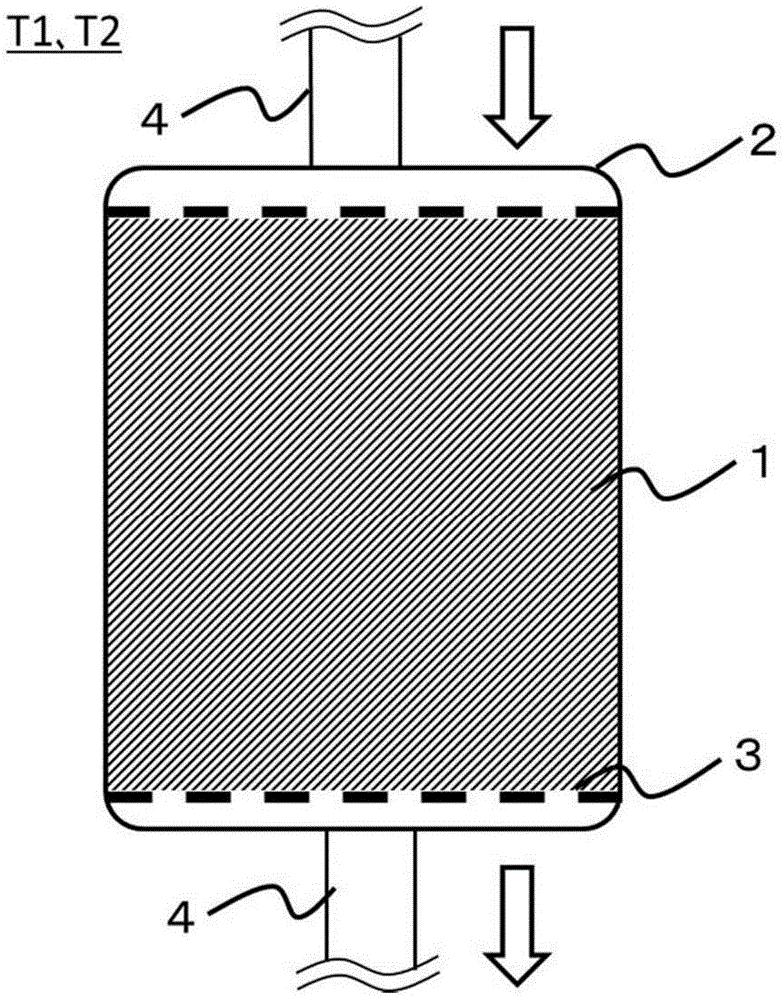

Method used

Image

Examples

Embodiment

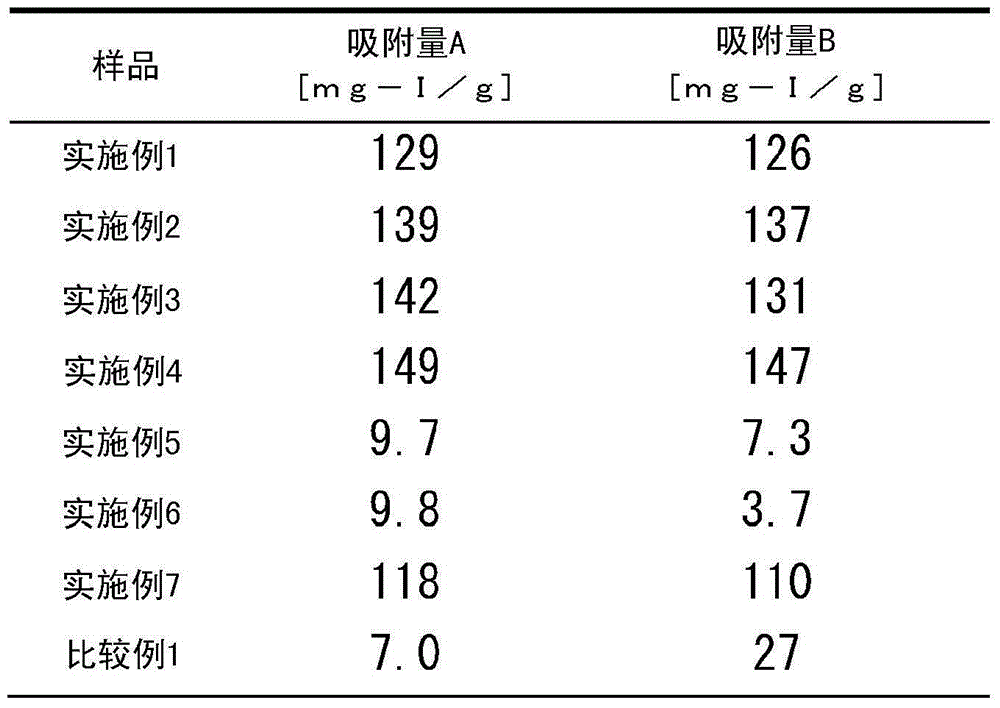

[0083]

[0084] Put 3-(2-aminoethyl)aminopropyltrimethoxysilane (9.4mL, 44mmol), toluene ( 10 mL) was stirred to obtain a homogeneous solution. Silica gel (particle diameter: 300 μm-500 μm, 6.7 g) containing 30% water was put in, and heated and stirred under reflux (oil bath: temperature: 110° C.) for 5 hours. Next, after cooling to room temperature, the supernatant was removed by decantation, and methanol was added thereto for washing, and then the supernatant was decanted (methanol washing and decantation were repeated twice). Next, the silica gel was transferred to a Kiriyama funnel, and washed with methanol. In this state, continue to attract and dry it. Thereafter, it was further dried under reduced pressure to obtain amine-modified silica gel as white particles (yield: 6.42 g).

[0085]Amine-modified silica gel (0.93 g) was placed in a vial (30 mL), and a 3 wt % silver nitrate aqueous solution (18.6 mL) was added thereto. After closing the lid, it covered with alum...

Embodiment 2

[0087] Put 3-mercaptopropyltrimethoxysilane (1.6mL, 10mmol), 3-(2-aminoethyl)aminopropyl Trimethoxysilane (2.3 mL, 11 mmol) and toluene (5 mL) were stirred to obtain a homogeneous solution. Silica gel (particle diameter: 300 μm-500 μm, 3.3 g) containing 30% water was put in, and heated and stirred under reflux (oil bath: temperature: 110° C.) for 5 hours. Next, after cooling to room temperature, the liquid phase was removed by decantation. Next, methanol (5 mL) was added to the flask, stirred, and the liquid phase was removed by decantation for washing (methanol washing and decantation were repeated five times). The remaining silica gel was transferred to a Kiriyama funnel, and washed with methanol. Suction was continued in this state, it was made to dry, and it dried under reduced pressure after that, and obtained the amine-mercapto modified silica gel as white particle (yield: 3.2 g).

[0088] Amine-mercapto-modified silica gel (0.50 g) was placed in a vial (20 mL), and a...

Embodiment 3

[0090] Change the amount of reagent used in Example 2 to 3-mercaptopropyltrimethoxysilane (2.5mL, 16mmol), 3-(2-aminoethyl)aminopropyltrimethoxysilane (2.0mL, 9.1mmol) , others were carried out as in Example 2, thereby obtaining the iodine adsorbent of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com