Numerical-control low-pressure casting machine

A low-pressure casting machine and numerically controlled technology, applied in the field of numerically controlled low-pressure casting machines, can solve problems such as economic loss, prone to explosion, poor heat resistance, etc., achieve scientific and reasonable structure, safe and convenient operation, and ensure fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

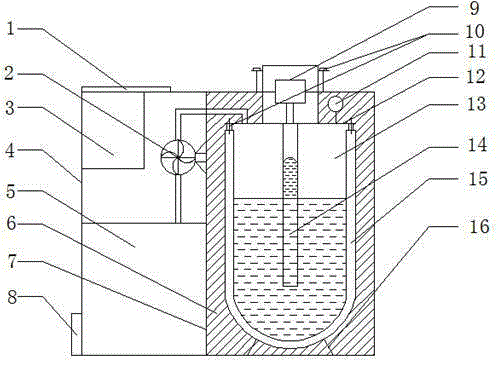

[0012] see figure 1 , the present invention provides a technical solution: a numerically controlled low-pressure casting machine, including a liquid crystal touch control panel 1, a turbo air compression pump 2, a main controller 3, a safety protection chassis 4, an air storage tank 5, and a composite material partition Plate 7, air valve 8, casting mold 9, fastening bolt 10, air pressure detection gauge 11, sealing cover 12, U-shaped material storage crucible 13, liquid rising conduit 14, high resistance heating layer 15 and bracket 16, air valve 8 is set On the left bottom of the safety protection cabinet 4, and the position corresponding to the inner left end of the safety protection cabinet 4, an air storage tank 5 is installed, the main contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com