Real-time detecting method and device for surface topography of swing arc MAG welding molten pool

A technology for real-time detection and molten pool surface, applied in measuring devices, arc welding equipment, optical devices, etc., can solve the problems of active gas shielded welding spatter, smoke and dust, and no observation method, etc., to reduce arc instability , optimize welding process parameters, improve the effect of weld forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

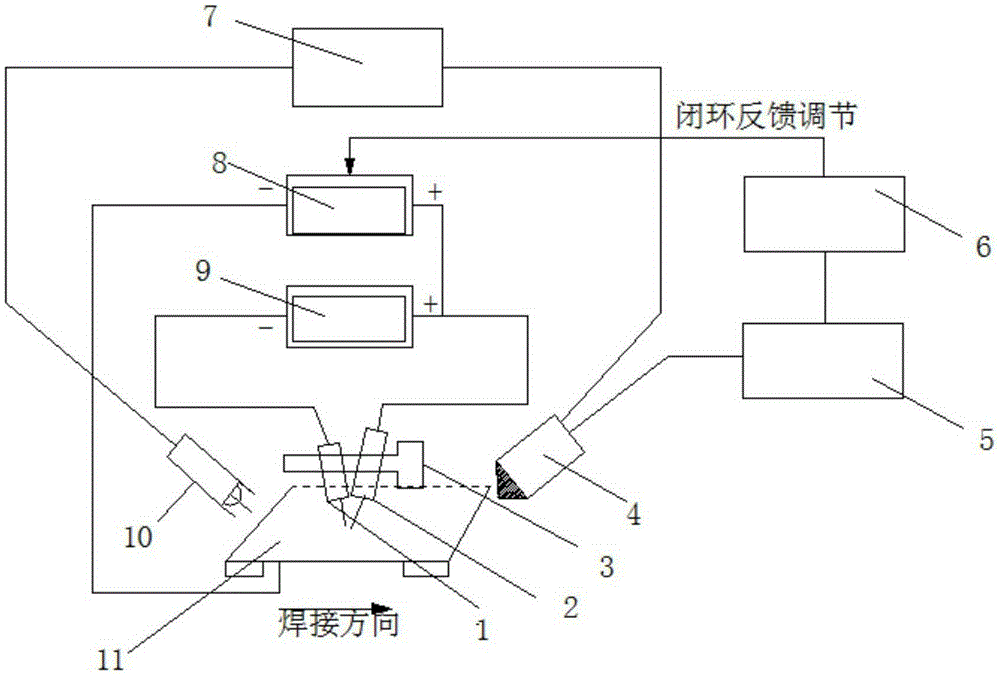

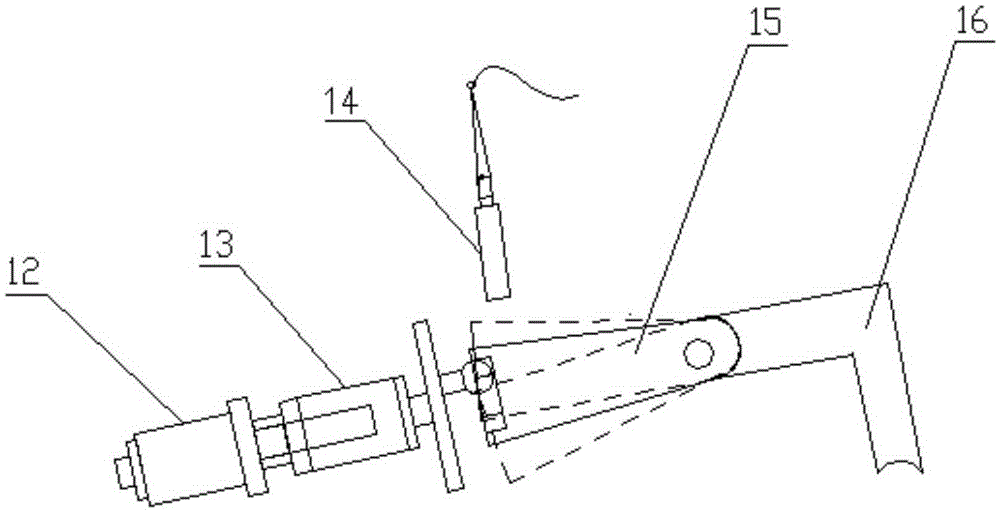

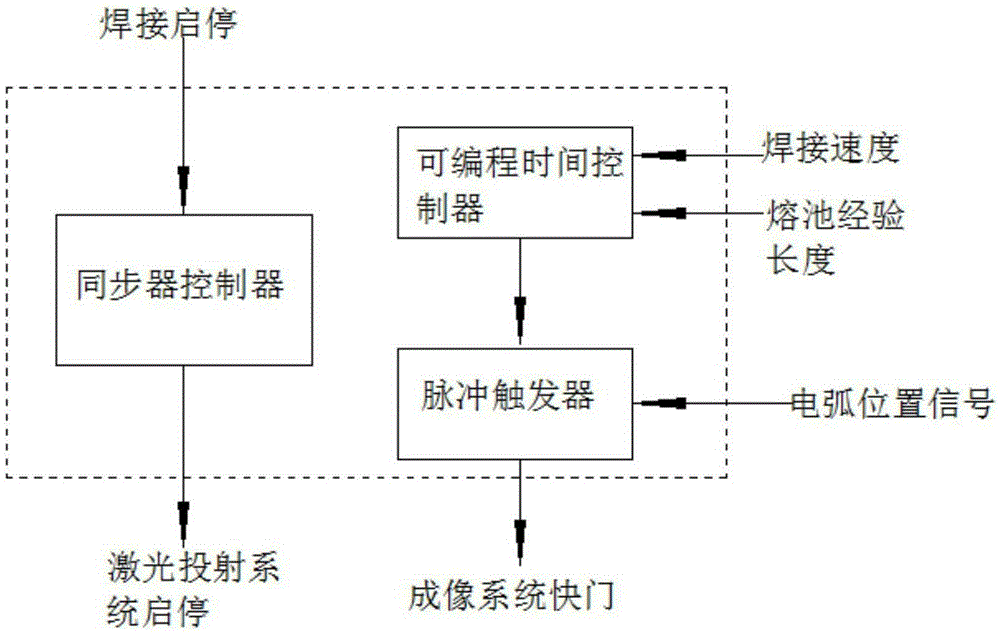

[0019] Example 1. The present invention discloses a real-time detection method and device for the surface topography of a swing arc MAG welding pool, mainly including a double-gun swing positioner, a laser projection system, an imaging system, a molten pool detection control system, and an image information processor and molten pool control system. Among them, the double-gun swing positioner is used for the synchronous swing control of MAG welding and TIG welding torches, and for positioning the arc swing position, so as to detect and control the molten pool and identify the welding seam deviation information; the laser projection system is used to project geometric laser stripes, and the imaging system is used for The deformed laser stripe image is collected, and the two are installed at a suitable position before and after the welding torch, and can move with the welding trolley to ensure real-time detection; on the one hand, the molten pool detection control system controls ...

example 2

[0021] Example 2. The present invention is applicable to an automatic welding seam tracking system based on oscillating arc sensing. According to the principle of arc tracking, the surface topography of the molten pool has a significant impact on the length of the arc, which in turn affects the welding current or welding voltage signal collected by Hall. Through the detection of the surface morphology of the swing arc welding molten pool, according to the surface height of the molten pool, its influence on the length change of the scanning arc can be analyzed, and the collected welding current or voltage signal can be corrected to obtain a more accurate weld deviation signal. Improved weld seam tracking accuracy with oscillating arc sensors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com