Method for preparing composite of pillared phyllosilicate and MFI type molecular sieve

A layered silicate, composite material technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, silicon compounds, etc., can solve the lack of microporous system, the single pore size of layered silicate, and limit the application in the field of catalysis and other problems to achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put 532ml deionized water, 9.1gNaF, 10.7gH 3 BO 3 , 8.66g of NaOH, 141ml of PEG300 (polyethylene glycol with an average molecular weight of about 300) solution is uniformly mixed, and 250ml of 40% silica sol solution is slowly added under vigorous stirring, transferred to a closed reactor, and reacted at 160°C for 70 hours. After the completion of the reaction, it was separated, washed with deionized water, and dried, and was identified as Kenyaite layered silicate by XRD. The product was named Ken-1.

Embodiment 2

[0027] Mix 15g Ken-1, 24g cetyltrimethylammonium bromide, 300g deionized water, stir for 2 hours, add 15g 25% tetrapropylammonium hydroxide solution, the weight ratio of the resulting mixture is: layered silicate : Cetyltrimethylammonium bromide: tetrapropylammonium hydroxide: water = 10:16:2.5:207.5. The mixture was reacted at 80°C for 24 hours. After the reaction, the product was separated, washed, and dried, and the product was named Ken-swell.

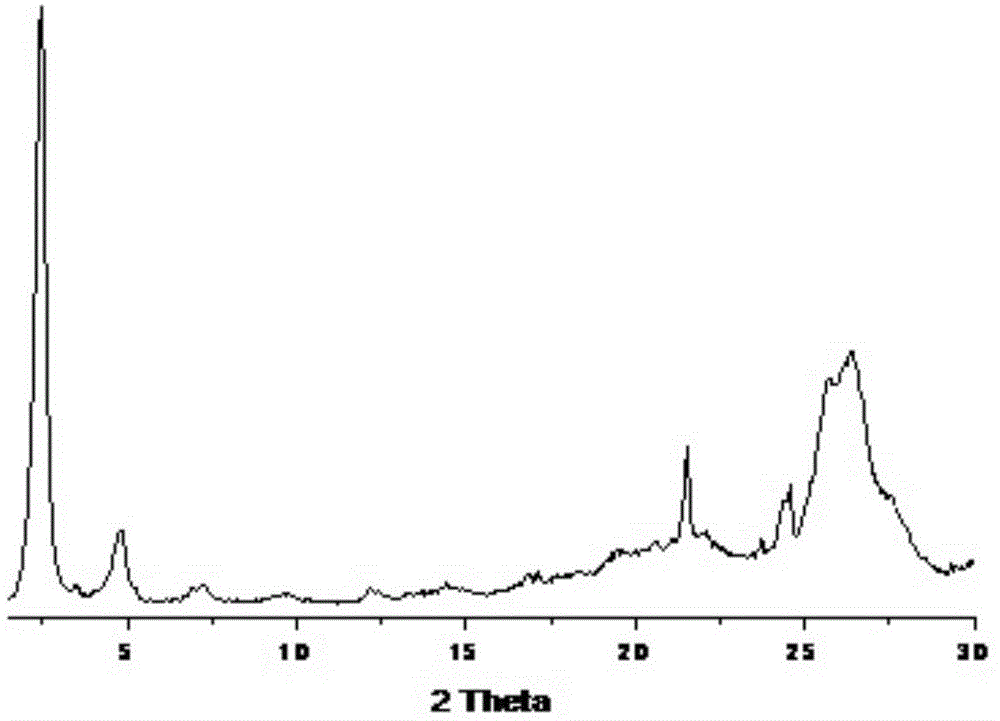

[0028] See Ken-swell’s XRD pattern figure 1 ,by figure 1 It can be seen that after puffing, the layer spacing of Kenyaite layered silicate increases to about

Embodiment 3

[0030] Mix 15g Ken-1, 75g cetyltrimethylammonium bromide, 465g deionized water, stir for 2 hours, add 60g 25% tetrapropylammonium hydroxide solution, the weight ratio of the resulting mixture is: Kenyaite layered silicic acid Salt: Cetyltrimethylammonium Bromide: Tetrapropylammonium Hydroxide: Water=10:50:10:340. The mixture was reacted at room temperature for 72 hours, and after the completion of the reaction, it was separated, washed, and dried, and the product was named Ken-swell-2.

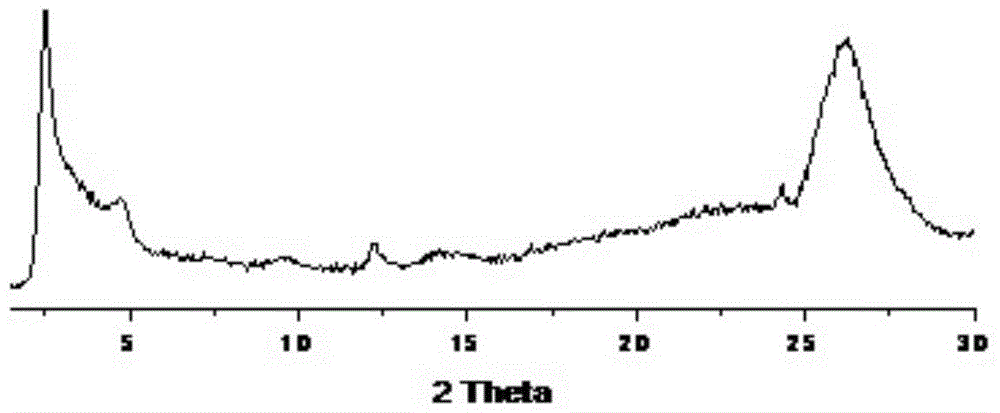

[0031] Ken-swell-2 was identified by XRD to have a Kenyaite layered structure, and the layer spacing increased to about

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com