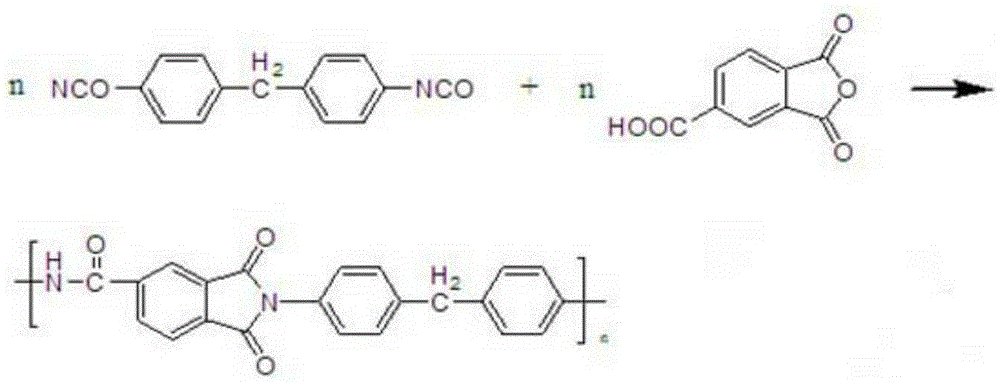

Polyimide polymer preparation method

A technology of polyimide and high polymer, which is applied in the field of preparation of polyimide high polymer, can solve the problems of cumbersome operation and high cost, and achieve the effects of simplified feeding steps, reduced production cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

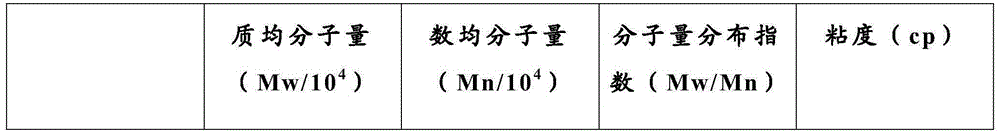

Examples

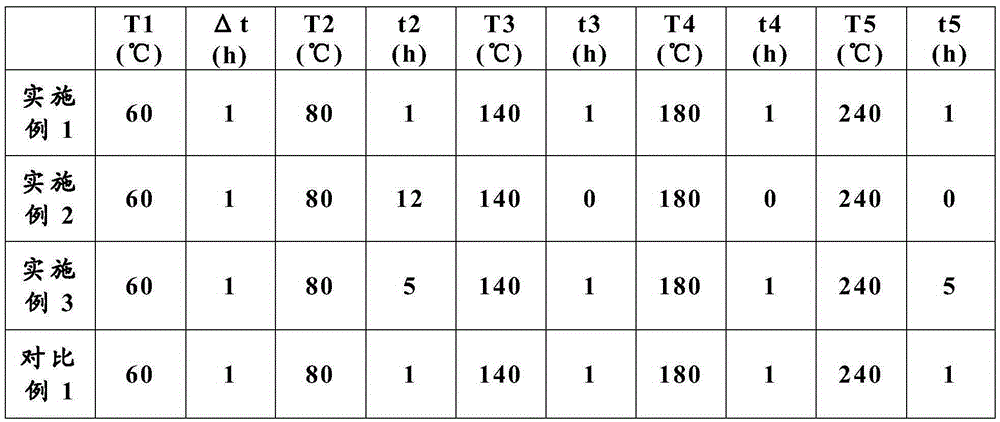

Embodiment 1 to 3

[0033]In the four-necked flask equipped with mechanical stirring and condenser, add 38.4g of trimellitic anhydride (TMA), 90mL of 1-methyl-2-pyrrolidone, stir evenly at T1 temperature, after TMA is completely dissolved, add 0.75mL of formic acid, and then Add 51g xylene diisocyanate (MDI) in three times, each time adding 17g, the time interval is Δt, then, keep the temperature at T2 temperature for a period of time, and the time is recorded as t2; keep the temperature at T3 temperature for a period of time, and the time is recorded as t3 Constant temperature for a period of time at T4 temperature, the time is recorded as t4; Constant temperature for a period of time at T5 temperature, the time is recorded as t5, stop the reaction, cool and discharge, the feed liquid is a dark brown transparent liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com