Steel wire rope coating

A steel wire rope and coating technology, which is applied in the direction of coating, anti-corrosion coating, asphalt coating, etc., can solve the problems of short service life of steel wire rope, impossibility of replenishing grease, difficulties, etc., and achieve good water resistance and corrosion resistance, prevent Seawater corrodes the steel wire and enters the inside of the wire rope to increase the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

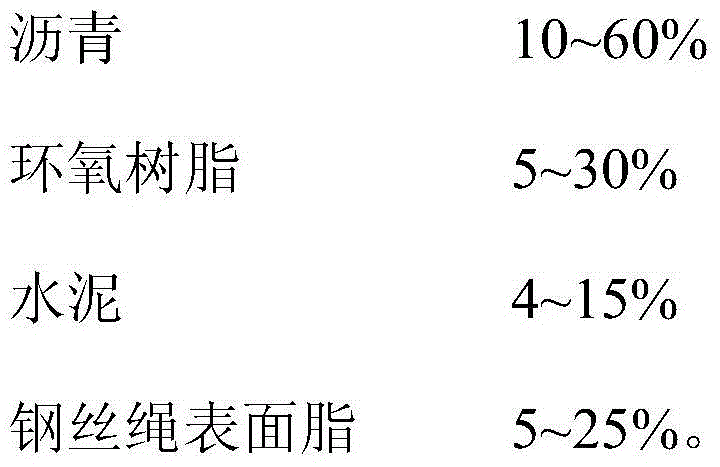

[0023] A kind of steel wire rope coating, described coating comprises by weight percentage:

[0024]

[0025] The dropping point of the grease on the surface of the steel wire rope is 55-65°C.

[0026] The kinematic viscosity of the grease on the surface of the steel wire rope is not less than 70m 2 / s.

Embodiment 2

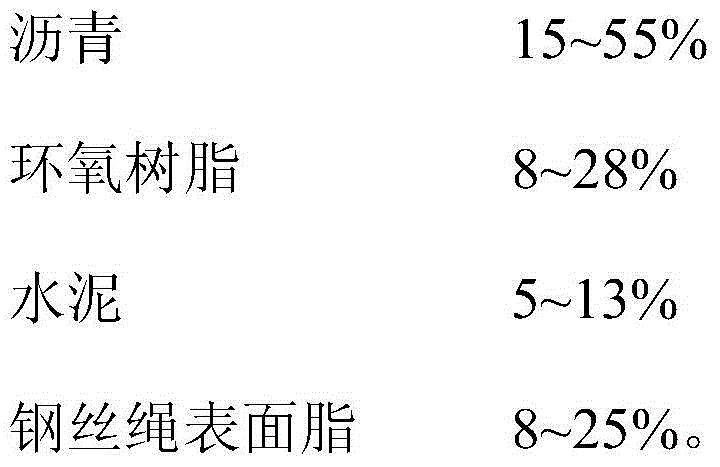

[0028] A kind of steel wire rope coating, described coating comprises by weight percentage:

[0029]

[0030] The dropping point of the grease on the surface of the steel wire rope is 55-65°C.

[0031] The kinematic viscosity of the grease on the surface of the steel wire rope is not less than 70m 2 / s.

Embodiment 3

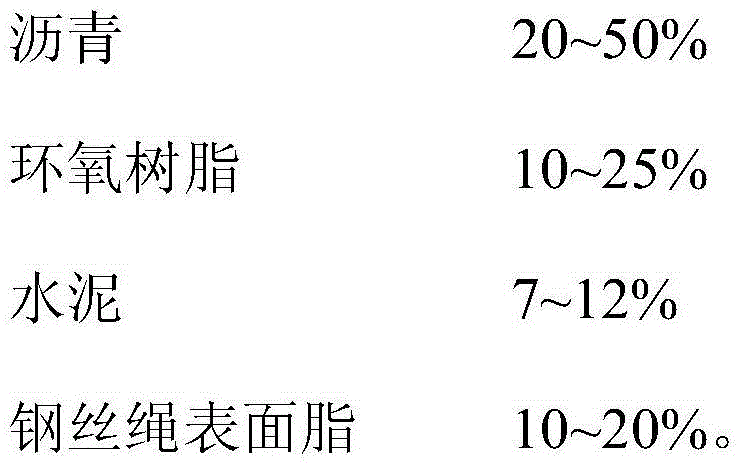

[0033] A kind of steel wire rope coating, described coating comprises by weight percentage:

[0034]

[0035] The dropping point of the grease on the surface of the steel wire rope is 56.5-63.5°C.

[0036] The kinematic viscosity of the grease on the surface of the steel wire rope is not less than 70m 2 / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com