Manufacturing method of greening groove for isolating white cement road

A manufacturing method and a technology for greening troughs are applied in the field of greening troughs to achieve the effects of traffic speed and safety guarantee, beautifying the city appearance and environment, and increasing vehicle traffic safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

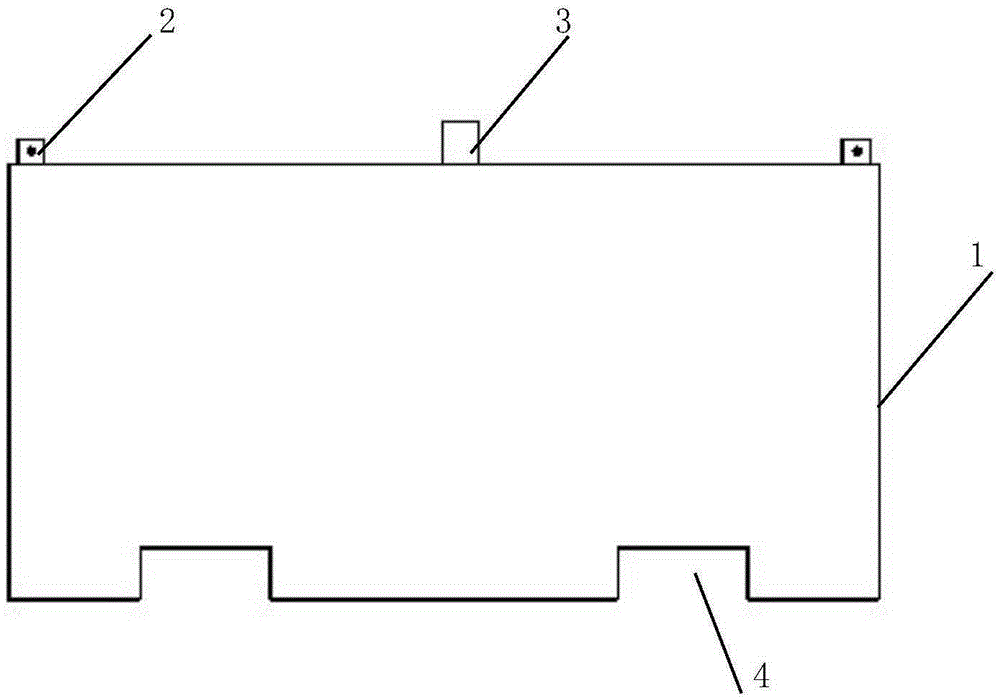

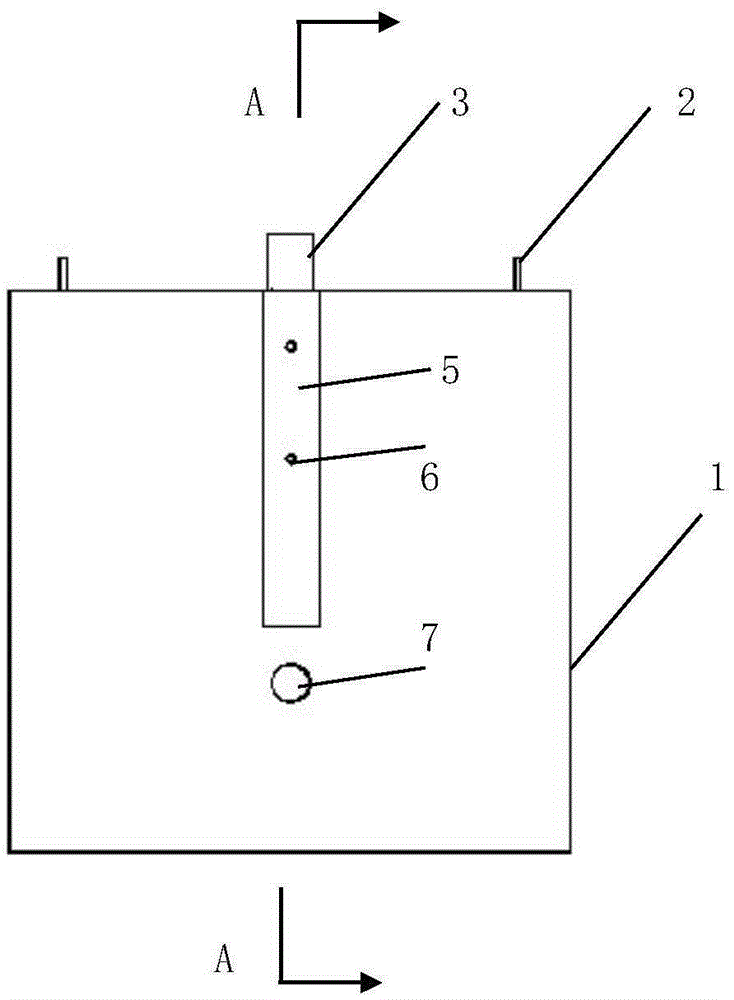

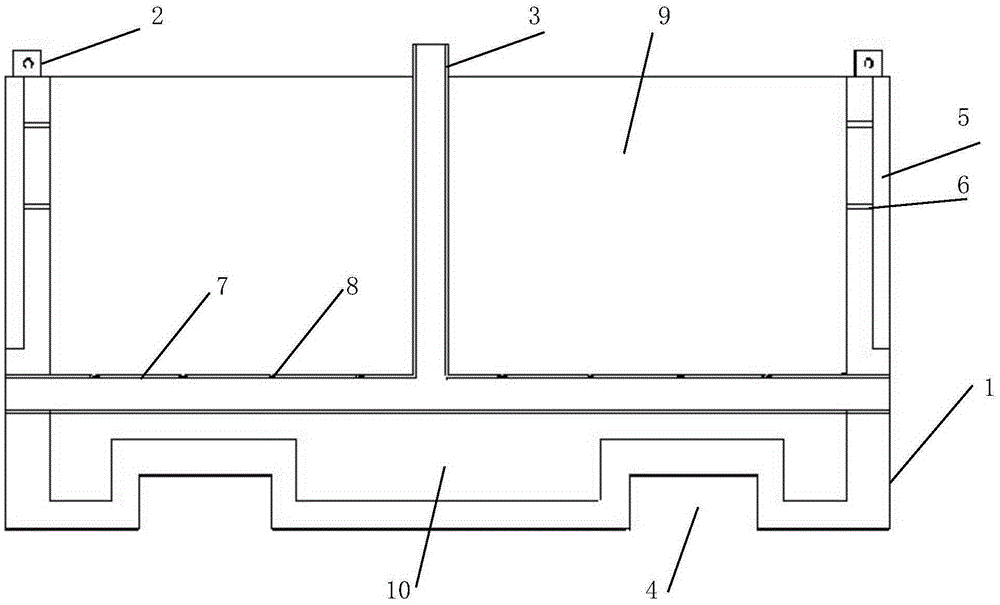

[0032] As shown in the figure: a white cement road isolation greening tank, including a greening tank body 1, a planting tank 9 is arranged in the greening tank body 1, and the described greening tank body 1 is a rectangular body, and the two ends of the rectangular body are provided with Inward groove 5, described greening tank body 1 inside is provided with the planting tank 9 that opens upwards, and the bottom of greening tank body 1 is provided with rectangular carrying hole 4, and planting tank 9 is provided with air intake pipe.

[0033] In order to increase the plant roots in the closed planting groove 9 to breathe air, in the longitudinal air intake pipe 3 in the middle of the planting groove 9, the upper end of the longitudinal air intake pipe 3 protrudes from the planting groove 9 to a certain height, and the lower end of the longitudinal air intake pipe 3 is provided with a horizontal air intake pipe. Trachea 7, the two ends of horizontal air inlet pipe 7 pass out th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com