Grid type concrete faced rockfill dam

A technology of concrete face and grid type, which is applied in the field of rockfill dam engineering, can solve problems such as uneven settlement and horizontal displacement, void between concrete face and rockfill body, mutual extrusion and damage of concrete face, and achieve the goal of reducing cracking Probability, large relative displacement, and strong structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

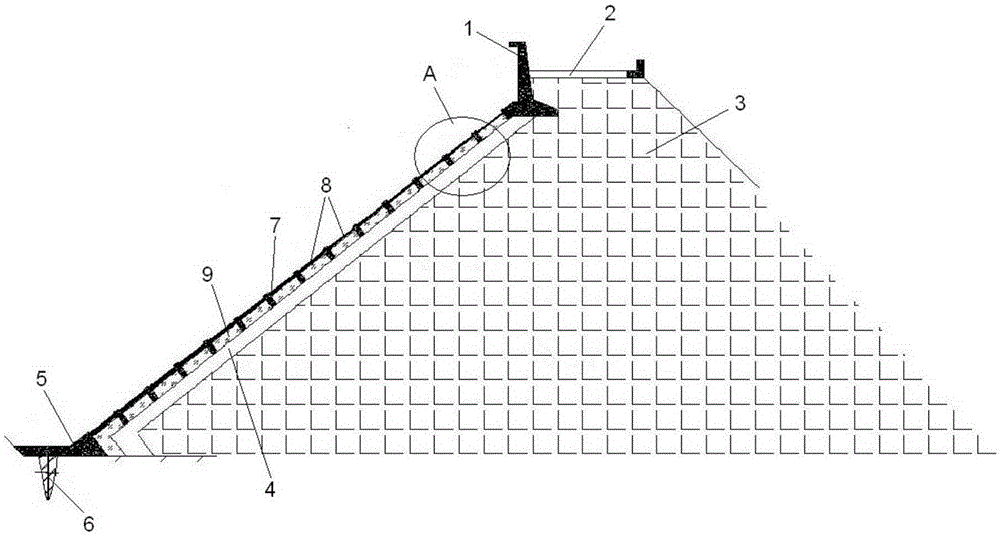

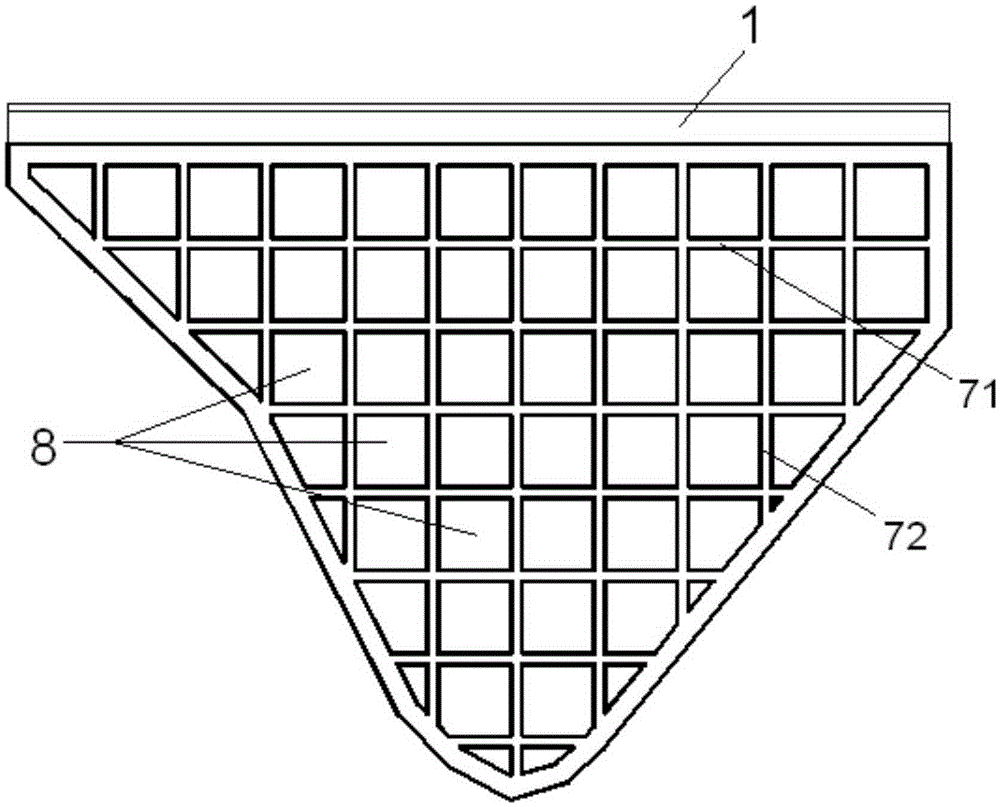

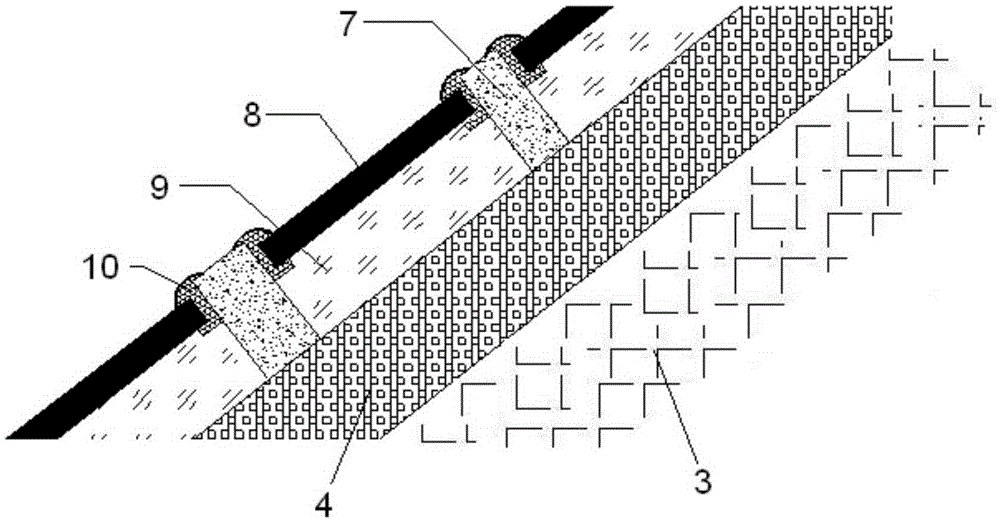

[0015] like figure 1 As shown in the figure, a grid-type concrete face rockfill dam includes: a wave break wall 1, a dam crest road 2, a rockfill area 3, a transition layer 4, a toe plate 5, and an anti-seepage curtain 6, and also includes: a reinforced concrete grid Grid 7, reinforced concrete panel 8, cushion 9, such as figure 2 As shown, the reinforced concrete grille 7 includes a transverse grille 71 and a longitudinal grille 72, a transition layer 4 is provided on the upstream surface of the rockfill area 3, and transverse grilles 71 intersecting with each other are provided on the upstream surface of the transition layer 4 , a longitudinal grid 72, a plurality of grid units are formed between the transverse grid 72 and the longitudinal grid 72, the grid unit is provided with a cushion 9, and a reinforced concrete panel 8 is provided on the cushion 9; The botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com