Easy-to-assemble split insulation cabin

A split-type, easy-to-assemble technology, applied in the field of shelters, can solve the problems of increased processing, transportation and deployment costs, high requirements for shelter transportation and deployment, unfavorable equipment overall installation and debugging, etc., to achieve airtightness Good, easy to transport, size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

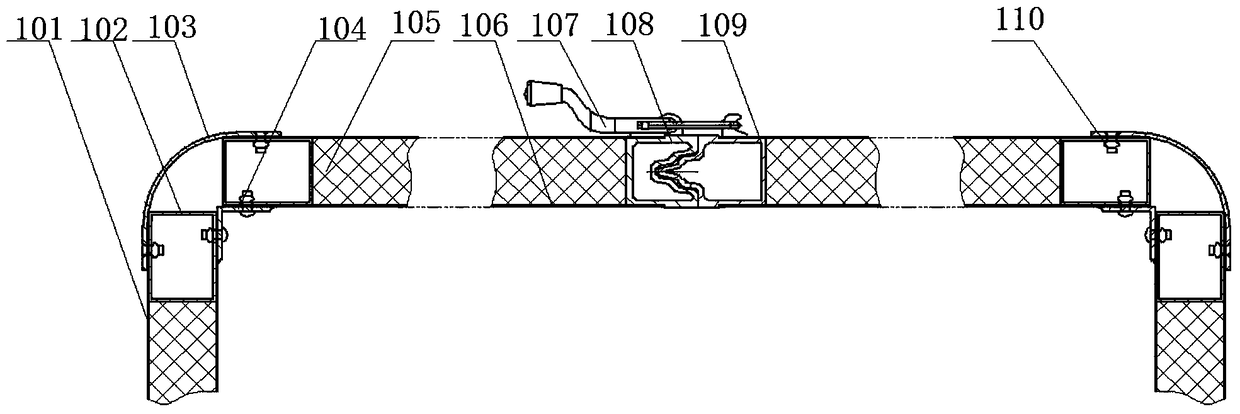

[0029] Such as figure 1 As shown, the detachable cabin body on the left side is mainly composed of an outer covering plate 101, an aluminum alloy rectangular tube 102, an outer wrapping angle 103, an inner bead 104, a polyurethane foam board 105, an inner covering plate 106, a concave aluminum profile frame 108 and a connecting device 110 The detachable cabin body on the right side is mainly made up of outer covering plate, aluminum alloy rectangular tube, outsourcing angle, inner bead, polyurethane foam board, inner covering plate, convex aluminum profile frame 109 and connecting device 110. The detachable cabin body on the left is welded with aluminum alloy rectangular tube 102 and concave aluminum profile frame 108 to form an integral frame; after installing the required embedded parts on the frame, the integral frame is filled with flame retardant, heat insulation The polyurethane foam board 105; the outer covering board 101, the inner covering board 106, the frame, and th...

Embodiment 2

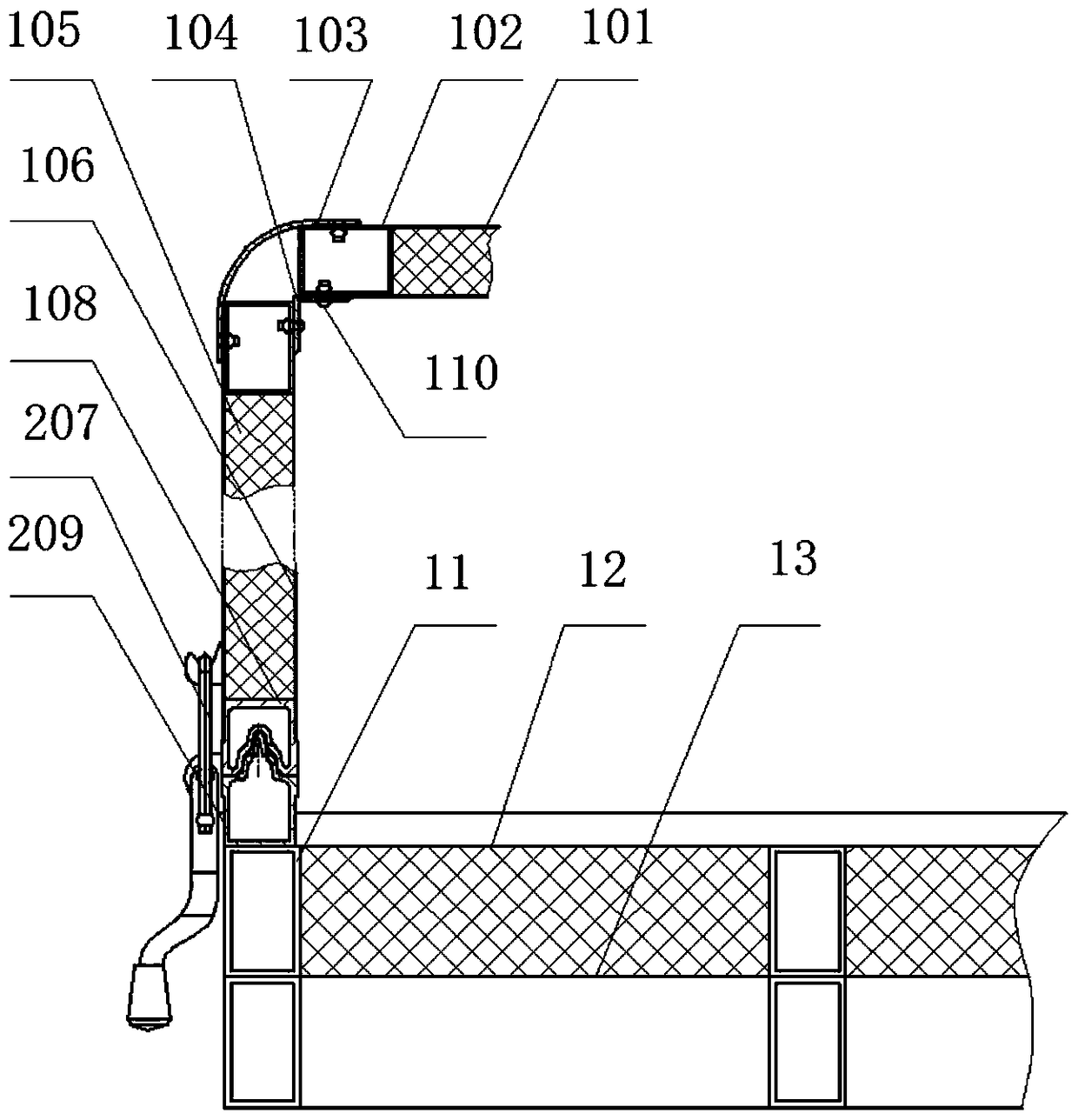

[0033] Such as figure 2 As shown: the detachable cabin body is mainly composed of outer covering board 101, aluminum alloy rectangular tube 102, outer wrapping angle 103, inner bead 104, polyurethane foam board 105, inner covering board 106, concave aluminum profile frame 108 and connecting device 110; The wall board is mainly composed of a convex aluminum profile frame 209, a rectangular tube 11, an inner bottom wall panel 12, an outer bottom wall panel 13, and a polyurethane foam board. The detachable cabin body is made the composite thermal insulation cabin body that lacks the hexahedron of two sides according to embodiment 1 method. The bottom wall plate is welded with rectangular tubes 11 to form a whole frame. After installing the required embedded parts on the frame, the polyurethane foam board with flame retardant, heat insulation and sound insulation is filled in the whole frame; 12. Bottom wall outer covering board 13, frame, and polyurethane foam board are bonded ...

Embodiment 3

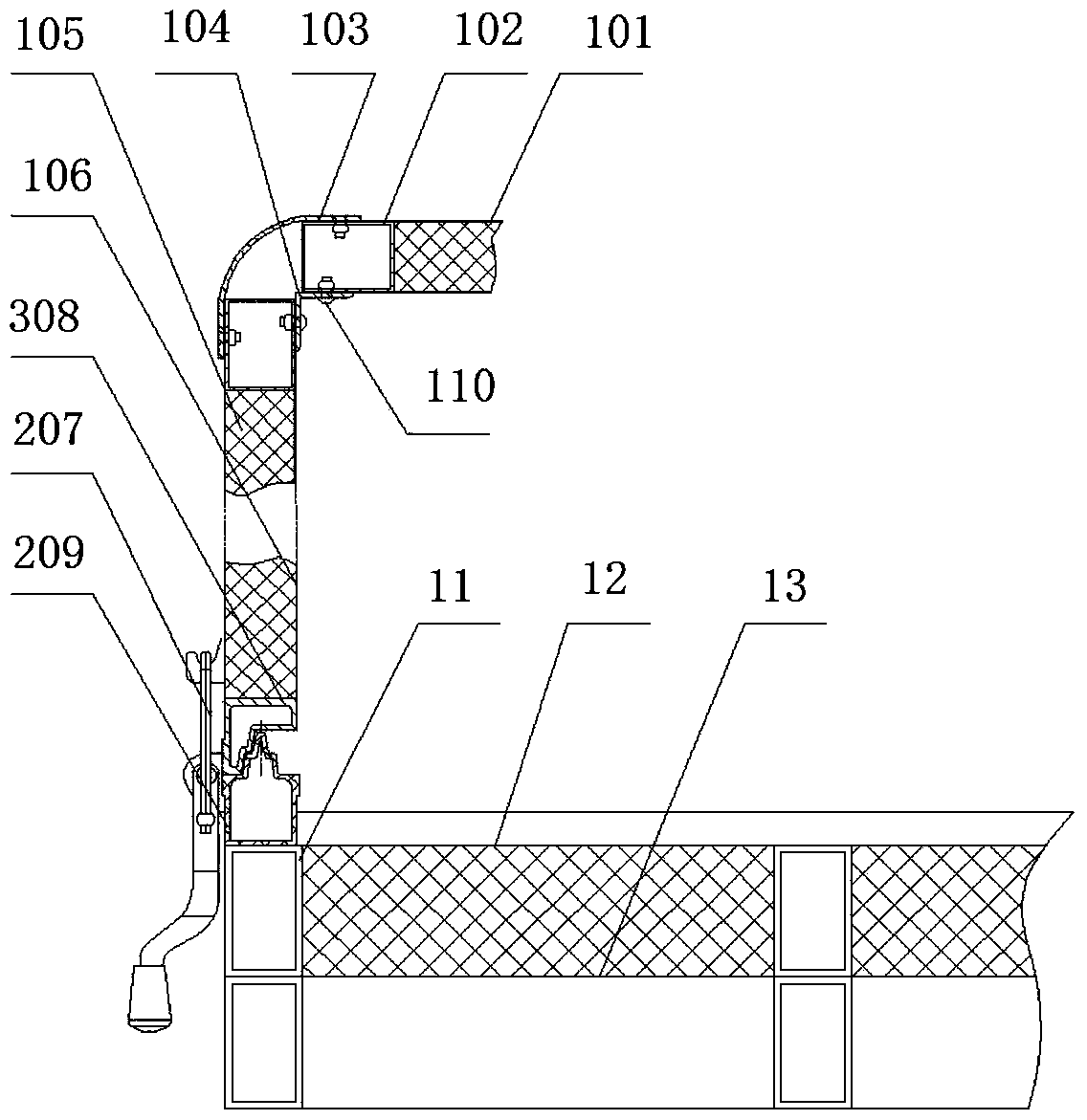

[0038] Such as image 3 As shown: the detachable cabin body is mainly composed of outer covering board 101, aluminum alloy rectangular tube 102, outer wrapping corner 103, inner bead 104, polyurethane foam board 105, inner covering board 106, semi-concave aluminum profile frame 308 and connecting device 110; The bottom wall board is mainly composed of a convex aluminum profile frame 209, a rectangular tube 11, an inner bottom wall panel 12, an outer bottom wall panel 13, and a polyurethane foam board. Detachable cabin body is made the composite insulation cabin body that lacks the hexahedron of two sides according to the method for embodiment 1. The bottom wall plate is made into a high-strength bottom plate according to the method in Example 2. It can be used as the rear wall plate structure of the detachable cabin body. After the detachable cabin body is in place using the limit guide rail in Embodiment 2, the semi-concave aluminum profile frame 308 of the detachable cabin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com