Tubing string rotation device

A technology of rotating device and tubing string, which is applied in drilling pipe, casing, production fluid, etc., can solve the problems of thinning and bursting of oil pipe, wear and tear of oil pipe, and inconspicuous structural effect, so as to improve economic efficiency and production, stop The effect of reducing the well phenomenon and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

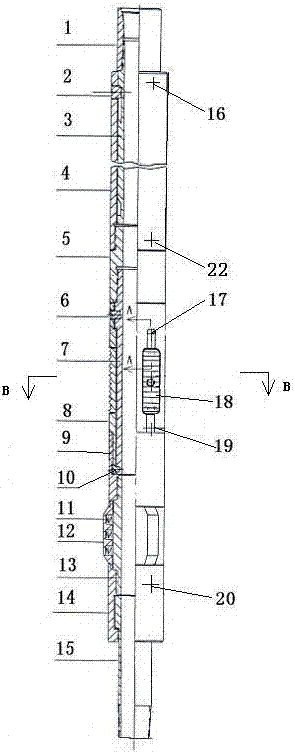

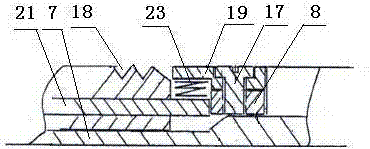

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

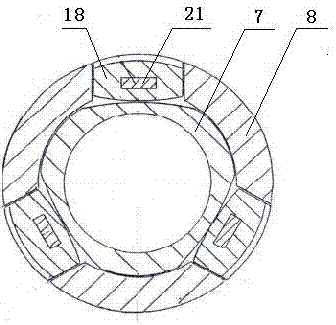

[0014] The track shaft 3 is composed of a through hole in the middle and two symmetrical 180-degree spiral track grooves 31 on the peripheral wall, such as Figure 4 , 5 , Shown in 6, there can be more than two track grooves according to the pipe diameter.

[0015] Rotation structure: the track sleeve 4 is installed outside the track shaft 3, the guide pin 2 is inserted into the track groove 31, the track shaft and the track cover are assembled into a dynamic body, and the two guide pins 2 respectively control the spiral track groove in the two track grooves 31 direction composition.

[0016] Righting resistance structure: three centering blocks 12 with springs 11 are evenly distributed on the outer periphery of the centering body 13 with a through hole in the middle and external threads at both ends, and the two ends of the centering block 12 are dyna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com