Construction method of blasting excavation for large-diameter pipeline in rock cavern wall

A large-diameter pipeline and construction method technology, which is applied to the construction field of large-diameter pipeline blasting and excavation, can solve the problems of difficult blasting quality control, difficult pipe grooves, loose surrounding rock, etc., so as to reduce the number of blasting cycles, shorten the construction period, The effect of reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it should not be understood that the scope of the above-mentioned theme of the present invention is limited to the above-mentioned embodiments.

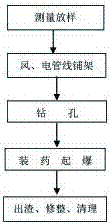

[0031] like figure 1 As shown, a construction method for blasting and excavating a large-diameter pipeline in a rock cavern wall includes the following steps:

[0032] (1) Measurement and setting out: measure the upper and lower contour lines of the pipe groove and the positions of the peripheral holes and cut holes along the axis of the hole. The peripheral holes are located on the contour line, and the cut holes are located in the middle of the upper and lower rows of peripheral holes. None greater than ± 5cm.

[0033] (2) Arrangement of wind and electricity pipelines: Arranged on the wall of the cave opposite the pipe groove not affected by excavation, the height shall not be less than 1.8m, in order to reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com